Method for preparing zinc oxide of spindle-shaped structure

A zinc oxide, spindle-shaped technology, applied in the field of zinc oxide preparation, can solve the problems of difficult separation, low zinc oxide yield, etc., and achieves the effects of low cost, simple preparation method and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

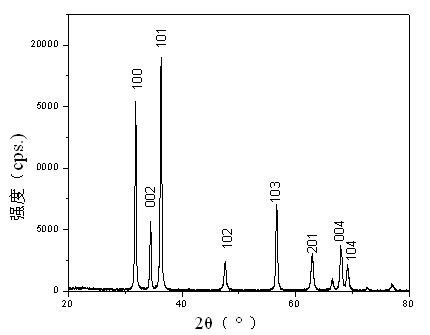

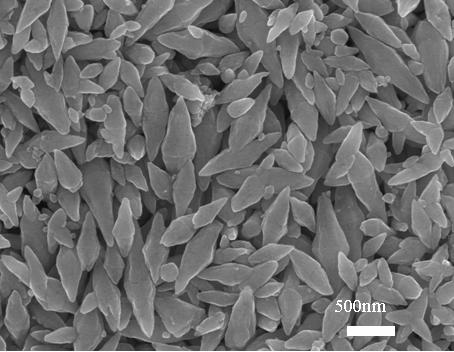

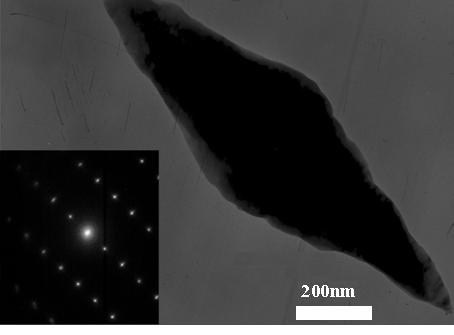

[0007] Specific embodiment one: the preparation method of a kind of spindle structure zinc oxide of this embodiment is carried out according to the following steps: one, preparation concentration is the zinc nitrate aqueous solution of 0.01mol / L~0.1mol / L; Two, under stirring condition, Add the sodium hydroxide aqueous solution with a concentration of 4.5mol / L~5.5mol / L dropwise into the zinc nitrate aqueous solution prepared in step 1 until the pH value of the solution is 9~11 to obtain a mixed solution; 3. Under stirring conditions , the temperature of the mixed solution obtained in step 2 was raised to 73°C-78°C and kept for 10h-24h to obtain the mixture; 4. The mixture obtained in step 3 was washed with deionized water and ethanol in sequence, and then heated at 60°C-90 Drying for 10h-24h at ℃ to obtain a white powder; 5. heat-treat the white powder obtained in step 4 in a sintering furnace at 500℃-700℃ for 1.5h-3h to obtain zinc oxide with a spindle structure.

[0008] The ...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the zinc nitrate aqueous solution in step 1 is 0.02 mol / L˜0.09 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the zinc nitrate aqueous solution in step 1 is 0.05 mol / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com