Method and device for processing laboratory exhaust gas

A waste gas treatment and laboratory technology, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve difficult problems such as effective treatment of waste gas, and achieve the effect of improving biodegradability and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Target exhaust gas

[0063] Hospital exhaust gas, mainly volatile formaldehyde, with an exhaust gas volume of 2000m 3 / h, the formaldehyde content is 8~50mg / m 3 , containing some volatile gases of disinfectants, such as ethanol, hydrogen peroxide, etc.

[0064] 2. Process parameters

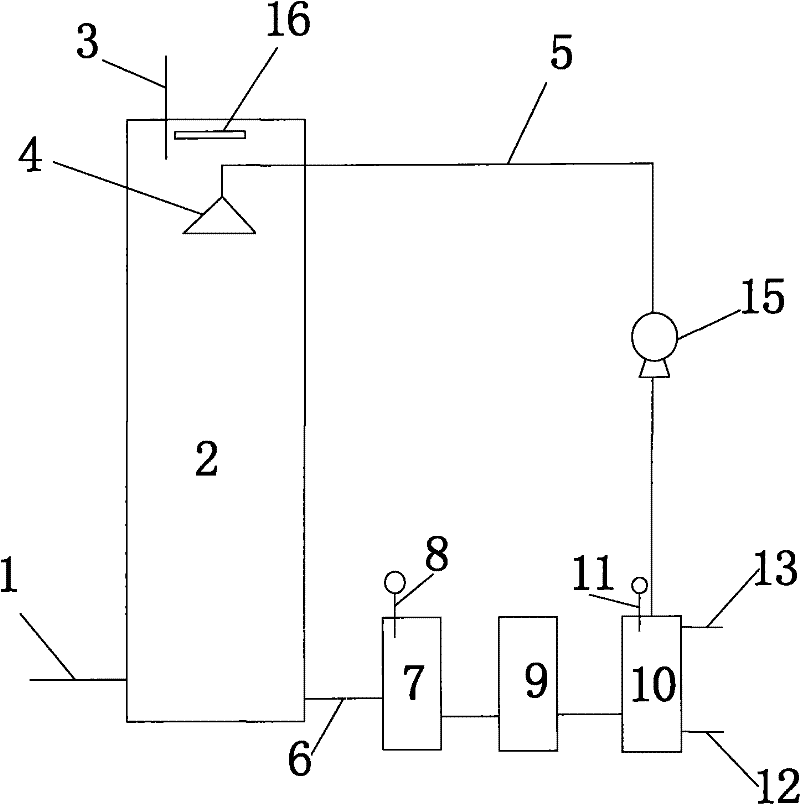

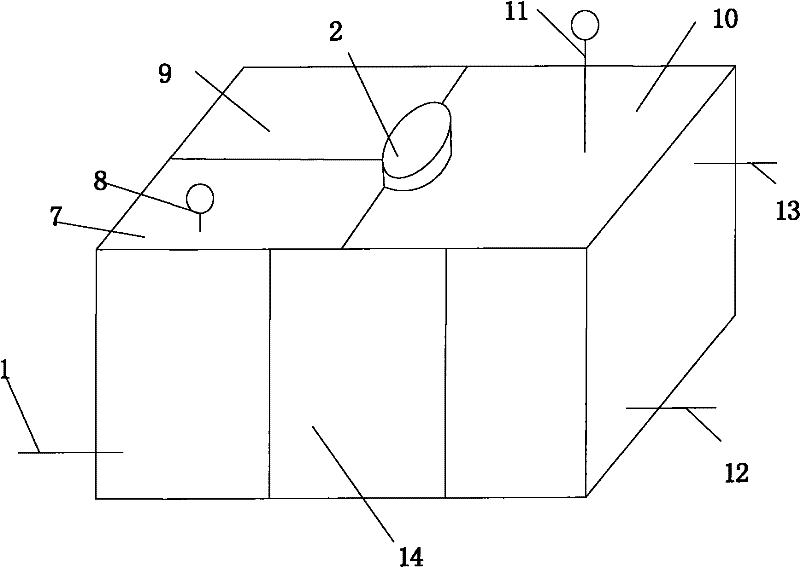

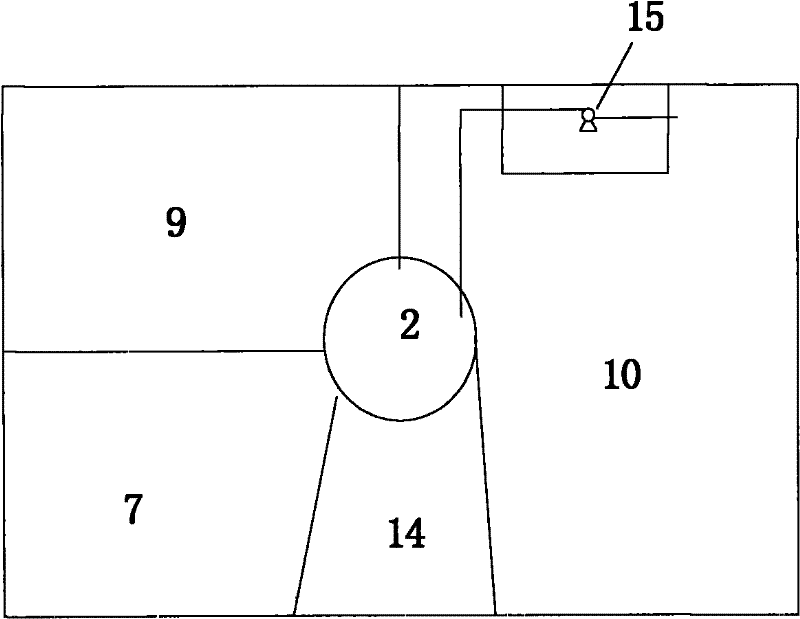

[0065] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

[0066] (1) Centrifuge speed 1200r.p.m

[0067] (2) Motor power 2.2kw

[0068] (3) Centrifugal washing machine: diameter × height = 400mm × 800mm

[0069] (4) Neutralization pool 7, because the waste gas contains less acid, it is mainly used for regulating the pool.

[0070] (5) Inner electrolytic cell 9:

[0071] Electrolytic material: It is composed of calcium carbonate, iron powder, carbon powder, magnesium phosphate salt, copper powder and titanium dioxide powder, and the proportions of each component are: 2%, 60%, 33%, 4.4%, 0.3%, 0.3% %.

[0072] The preparation m...

Embodiment 2

[0081] 1. Target exhaust gas

[0082] The waste gas is the acid waste gas discharged from the drug cabinet, which contains perchloric acid, hydrogen chloride, sulfuric acid, nitric acid and its mixture aqua regia. Exhaust gas volume at 450m 3 / h~800m 3 / h.

[0083] 2. Process parameters

[0084] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

[0085] (1) The speed of the centrifuge is 1350r.m.p.

[0086] (2) Motor power 0.75kw

[0087] (3) Centrifugal washing machine: diameter × height = 250mm × 700mm

[0088] (4) Neutralize pool 7 and adjust the pH to 8

[0089] (5) Inner electrolytic cell 9:

[0090] Electrolytic material: It is composed of calcium carbonate, iron powder, and carbon powder, and the proportions of each component are: 25%, 40%, 35%,

[0091] (6) Biological adsorption pool 10:

[0092] Filler: Suspended activated carbon powder, cellulose ether filler can be omitted.

[0093] 3. The effect of wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com