Rare earth complex and preparation method and application thereof

A technology of rare earth complexes and rare earth salts is applied in the field of rubber additives to achieve the effects of improving heat resistance, promoting vulcanization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

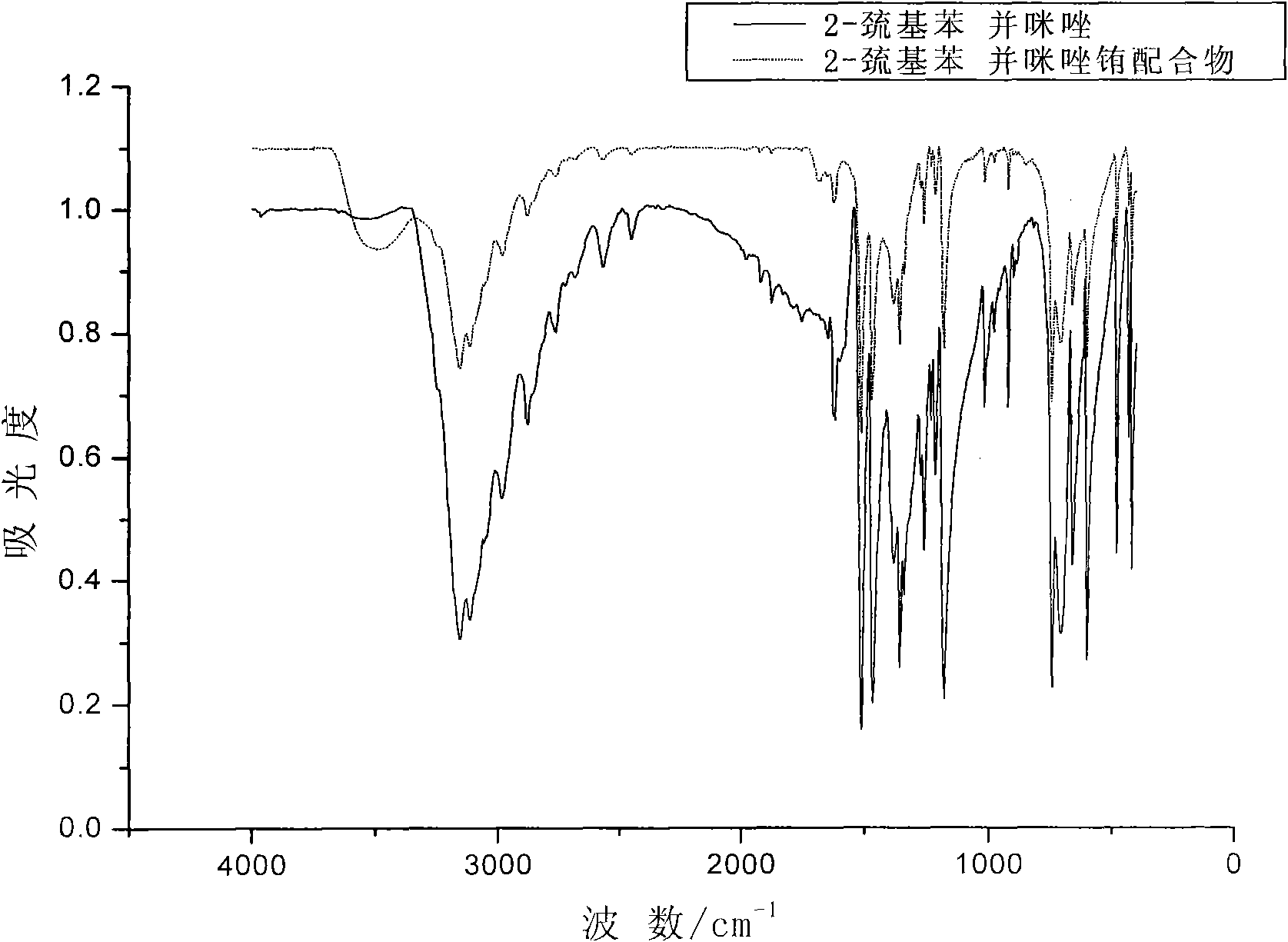

[0023] 22.5g (0.15mol) 2-mercaptobenzimidazole (MB) was dissolved in 200ml ethanol-water solution, and 150ml 0.33mol / l europium chloride (EuCl 3 ·6H 2 O 0.05mol) ethanol solution, stirred and reacted at 70°C for 1 hour. The precipitate generated by the reaction was filtered, washed with 1:1 ethanol-acetone solution until no chloride ions were found in the filtrate with acidified silver nitrate solution, and then dried in a vacuum oven to constant weight to obtain a light yellow powder product. Yield: 92%. Elemental analysis: the Eu, C, H, N, and S contents of the product are 30.01%, 33.11%, 2.80%, 11.08%, and 12.23%, respectively, and the chemical formula Eu(MB) 2 (OH)·2H 2 O match. Infrared spectroscopy (FTIR) analysis results are as follows figure 1 shown. Among them, the complex is at 1464cm -1 and 645cm -1 The nearby absorption peaks are the resonance absorption peak N=C-S of the exocyclic sulfur atom and the imidazole ring and the C-S stretching vibration absorpti...

Embodiment 2

[0025] Dissolve 9.84g (0.06mol) of 2-mercaptomethylbenzimidazole (MMB) in 100ml of ethanol-water solution, slowly add 100ml of 0.2mol / l samarium chloride (SmCl 3 ·6H 2 (0.02mol) ethanol solution, stirred and reacted at 20°C for 5 hours. The precipitate formed by the reaction was filtered under reduced pressure, washed with 1:1 ethanol-acetone solution until the filtrate was tested with acidified silver nitrate solution to detect no chloride ions, and then dried in a vacuum oven to constant weight to obtain a light yellow powder product. Yield: 89%. Elemental analysis: the Sm, C, H, N, and S contents of the product are 28.01%, 36.13%, 3.80%, 10.08%, and 12.03%, respectively, and the chemical formula Sm(MMB) 2 (OH)·2H 2 O match. FTIR: The characteristic absorption peak of the organic segment of the complex is basically consistent with the spectrum of the ligand MMB, where the complex is at 1466 and 660cm -1 The nearby absorption peaks are the resonance absorption peak N=C-S...

Embodiment 3

[0027] With 2-mercaptobenzimidazole as a ligand and rare earth lanthanum as a central ion, the lanthanum complex of 2-mercaptobenzimidazole is prepared according to the above steps, and the structural formula is La(MB) 2 (OH)·H 2 O, denoted as La-MB.

[0028] Rare earth complex anti-aging performance test basic formula: natural rubber 100; zinc oxide 3; stearic acid 2; accelerator CZ 1.5; accelerator DM 0.5; sulfur 1.5; antioxidant La-MB or 4010NA2.

[0029] Mixing and vulcanization process: First pass the natural rubber on the φ160 open mill for 6 times (roll distance 0.5mm). Add the rare earth organic complex and other compounding ingredients according to the conventional mixing method, and add sulfur at the end. The rubber is vulcanized on a flat vulcanizer at 143°C and 15MPa, and the positive vulcanization time T90 is measured by a vulcanizer. The vulcanized samples were placed at room temperature for 24 hours, and then tested for physical and mechanical properties.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com