Anti-aging light conversion film and preparation method thereof

An anti-aging and thin-film technology, which is applied in chemical instruments and methods, luminescent materials, plant protection covers, etc., can solve the problem of unsatisfactory utilization, decline of light conversion performance of organic light conversion agents, weak anti-ultraviolet aging ability of light conversion agents, etc. Problems, to achieve the effect of improving application value, improving anti-ultraviolet aging ability, and improving anti-ultraviolet aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

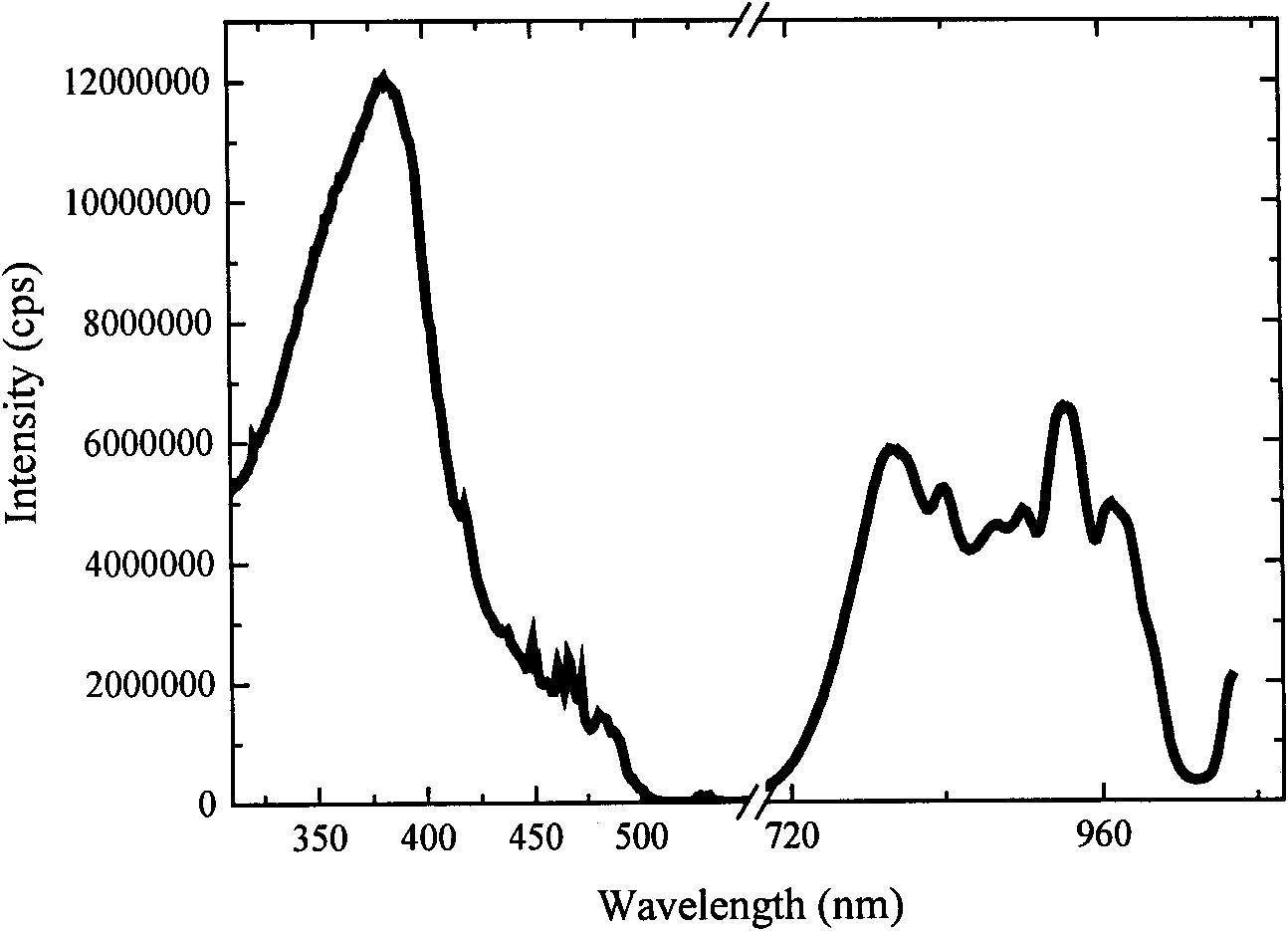

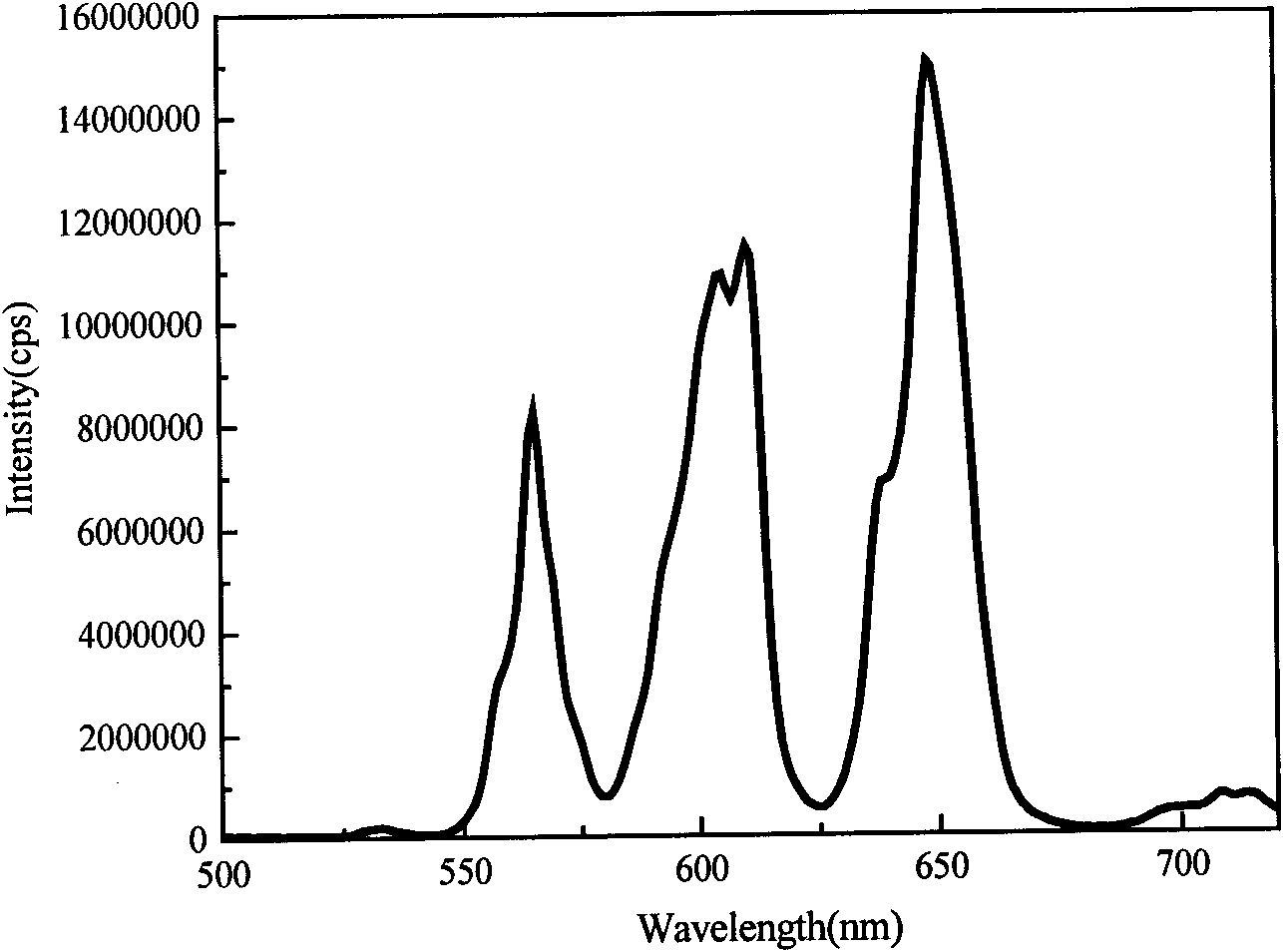

[0022] Weigh tetraethyl orthosilicate and absolute ethanol according to the ratio of 1:25 by volume to form solution I; weigh distilled water and solution I according to the ratio of 1:15 by volume, and pass through 0.1M ammonia water Adjust the pH value to 9 to prepare Sol II; make the rare earth light converting agent Sm 0.5 Yb 0.5 (TTA) 3 Add phen to Sol II at a ratio of 5.0g / L, heat and react in a water bath at 40°C for 8 hours to obtain a precipitated product; filter the reaction product, wash twice with absolute ethanol and distilled water, and dry in an oven at 60°C , making SiO 2 Surface Modified Sm 0.5 Yb 0.5 (TTA) 3 phen light conversion agent, the excitation spectrum and emission spectrum of the light conversion agent are as follows figure 1 with figure 2 shown. Then, the SiO 2 Surface Modified Sm 0.5 Yb 0.5(TTA) 3 The phen light-changing agent is dispersed in 100 parts by weight of PVC polymer in parts by mass of 1.5 parts, dispersed by a blending meth...

Embodiment 2

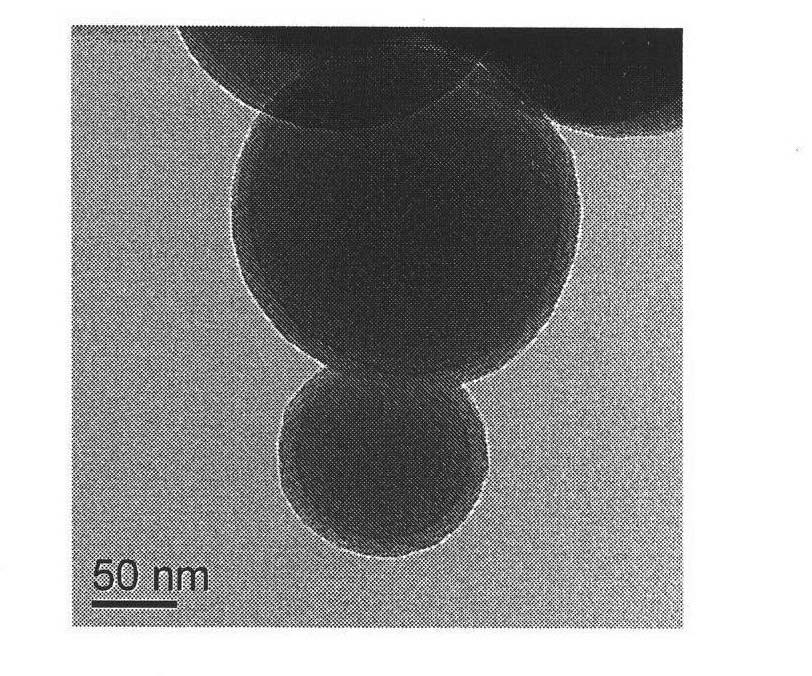

[0024] Weigh tetraethyl orthosilicate and absolute ethanol at a ratio of 1:15 by volume to form solution I; weigh distilled water and solution I at a ratio of 1:12 by volume, and adjust the pH with 0.05M sodium hydroxide solution value to 8, formulated as Sol II; the rare earth light-transforming agent Sm 0.5 Tb 0.5 (TTA) 3 Add phen to Sol II at a ratio of 5g / L, heat and react in a water bath at 50°C for 6 hours to obtain a precipitated product; filter the reaction product, wash twice with absolute ethanol and distilled water, and dry it in an oven at 80°C. Prepared SiO 2 Surface Modified Sm 0.5 Tb 0.5 (TTA) 3 phen light conversion agent, its transmission electron microscope picture is as follows image 3 As shown, it can be seen from the transmission electron microscope that the light conversion agent Sm 0.5 Tb 0.5 (TTA) 3 phen has been replaced by SiO 2 Wraps up nicely. SiO 2 Surface Modified Sm 0.5 Tb b 0.5 (TTA) 3 The phen light-changing agent is dispersed i...

Embodiment 3

[0026] Weigh absolute ethanol and butyl titanate at a volume ratio of 6:1, dissolve them, and make solution I; weigh absolute ethanol, distilled water, and acetic acid at a volume ratio of 6:2:1, and make solution II ; Solutions I and II were mixed and reacted in a volume ratio of 8:1, and the pH value was adjusted to 5 with 1.0M HCl, and Sol III was obtained after sufficient stirring; the Sm 0.3 Gd 0.4 Yb 0.3 (TTA) 3 Dipy 2 Rare earth light-changing agent was added to Sol III at a ratio of 6.0g / L, reacted in a water bath at 40°C for 6 hours, and a precipitated product was obtained; the product was filtered, washed repeatedly with absolute ethanol and distilled water for 3 times, and dried in an oven at 50°C , making TiO 2 Surface Modified Sm 0.3 Gd 0.4 Yb 0.3 (TTA) 3 Dipy 2 Rare earth organic light conversion agent. TiO 2 Surface Modified Sm 0.3 Gd 0.4 Yb 0.3 (TTA) 3 Dipy 2 The rare-earth organic light-changing agent is dispersed in 100 parts of PE polymer in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com