Primer coating for extrusion complex of soft package and applications thereof

A technology of extrusion compounding and flexible packaging, which is applied in the field of fine chemistry, can solve the problems that packaging materials cannot be used for boiling, poor drying of the composite layer, and narrow range of composite substrates, etc., to increase the interface bonding strength and water resistance , improve composite fastness, good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

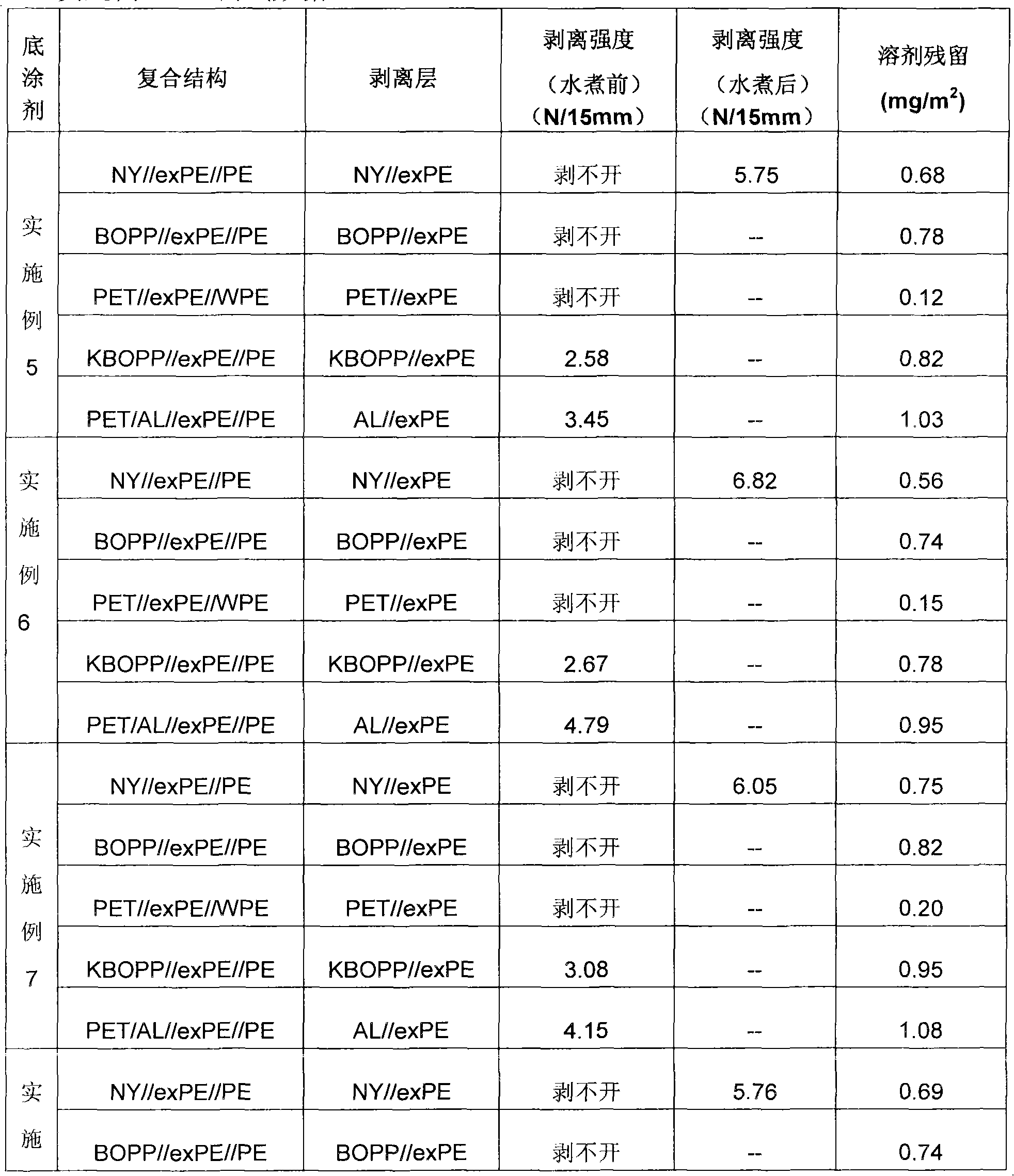

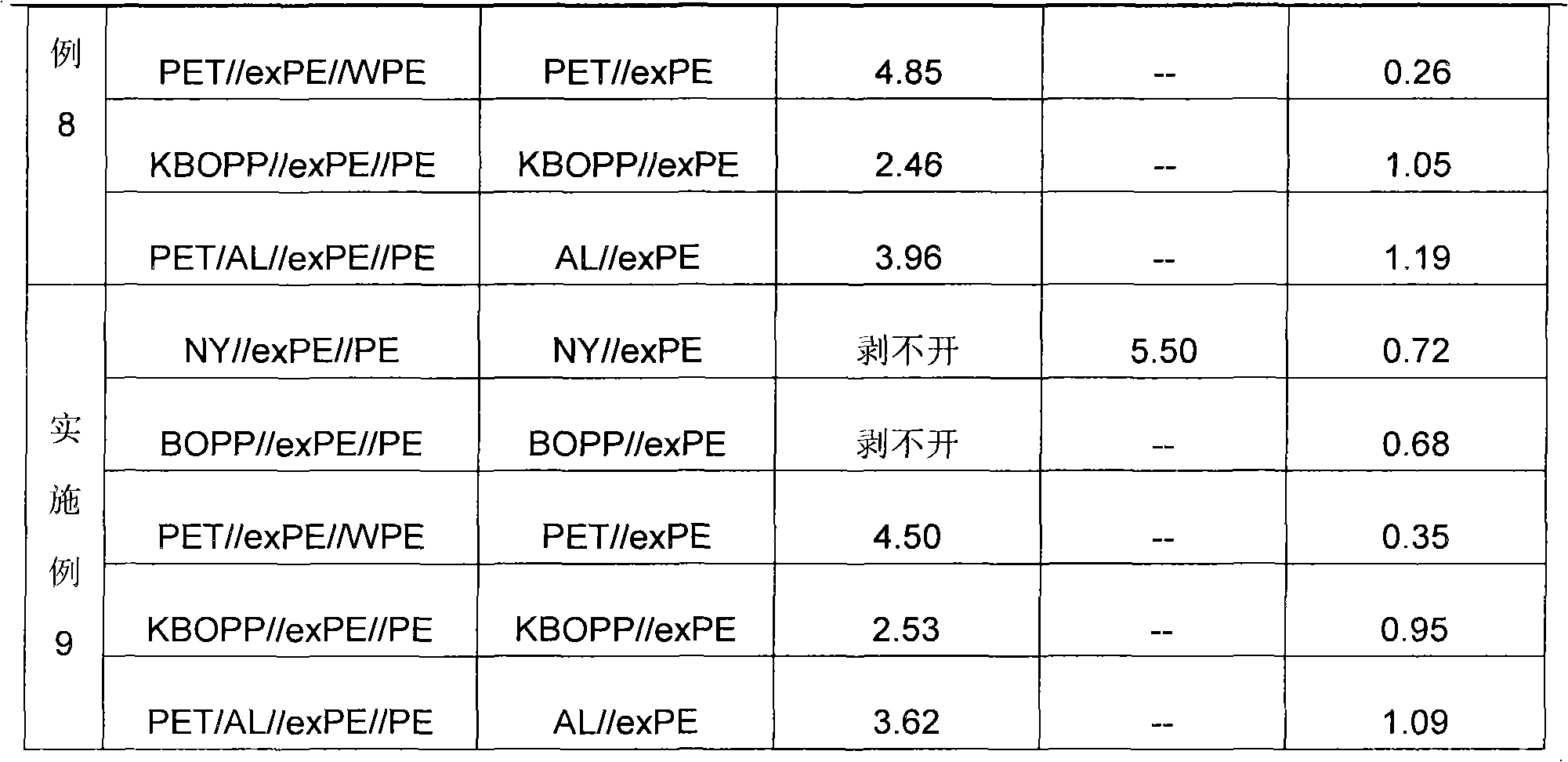

Examples

Embodiment 1

[0018] Embodiment 1: Containing hydroxy-terminated styrene-butadiene liquid rubber polyester polyol

[0019] In this example, polyester polyol containing hydroxy-terminated styrene-butadiene liquid rubber is composed of dibasic acid compounded with adipic acid and isophthalic acid, polyol compounded with diethylene glycol and trimethylolpropane, and hydroxy-terminated styrene-butadiene liquid rubber is bulk polymerized Formed, the raw material additions by weight percentage are respectively: 20% adipic acid, 29% isophthalic acid, 45% diethylene glycol, 2% trimethylolpropane, 4% hydroxy-terminated styrene-butadiene liquid rubber %, the polymerization operation is: add isophthalic acid, adipic acid, diethylene glycol, trimethylolpropane, and hydroxy-terminated styrene-butadiene liquid rubber into the reactor, heat up and stir, and the temperature in the kettle is controlled at 150- 300°C, when the water output reaches the required water output (for example, 5-15g of water per 10...

Embodiment 2

[0021] The operation process is the same as in Example 1. In this example, the polyester polyol containing hydroxy-terminated styrene-butadiene liquid rubber is formed by bulk polymerization of dibasic acid compounded with adipic acid and terephthalic acid, diethylene glycol, and hydroxy-terminated styrene-butadiene liquid rubber. , The raw materials calculated by weight percentage are respectively: 22% of adipic acid, 28% of terephthalic acid, 44% of diethylene glycol, and 6% of hydroxy-terminated styrene-butadiene liquid rubber.

Embodiment 3

[0023] The operation process is the same as in Example 1. This example contains polyols composed of hydroxy-terminated styrene-butadiene liquid rubber polyester polyols composed of dibasic acids composed of terephthalic acid and isophthalic acid, ethylene glycol and diethylene glycol compounded polyols and Hydroxy-terminated styrene-butadiene liquid rubber is polymerized. The raw materials in terms of weight percentage are: 20% terephthalic acid, 25% isophthalic acid, 35% diethylene glycol, 12% ethylene glycol, and hydroxy-terminated butyl Benzene liquid rubber 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com