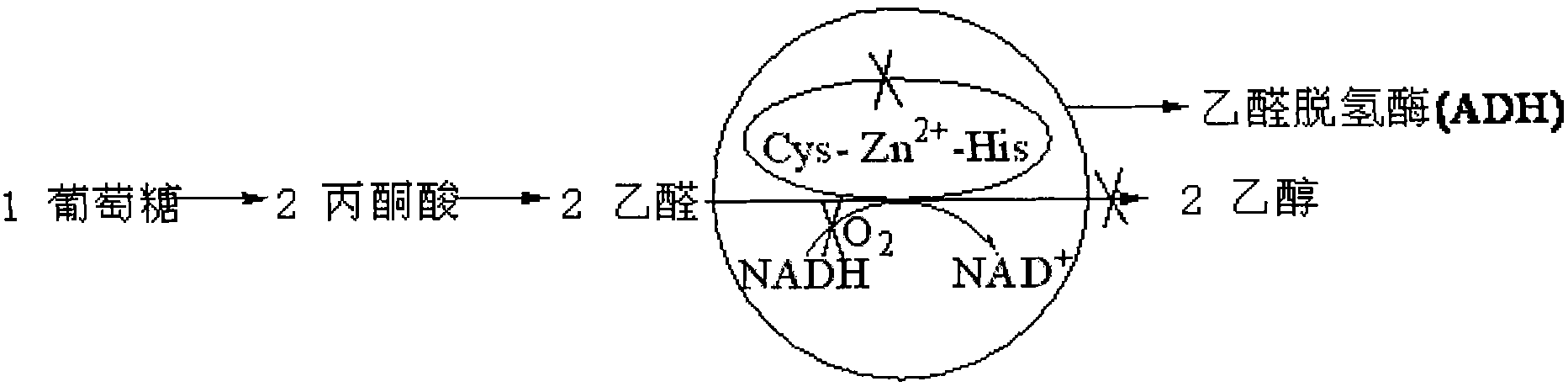

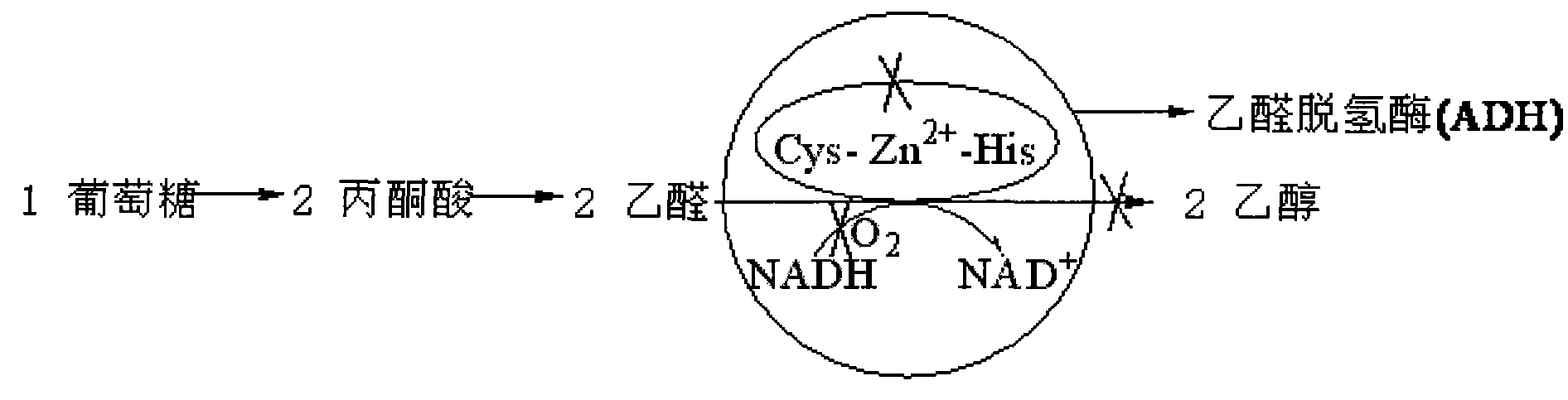

Technology for producing acetaldehyde in one step in microbial fermentation method

A microbial fermentation method, acetaldehyde technology, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problem of high cost of acetaldehyde, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

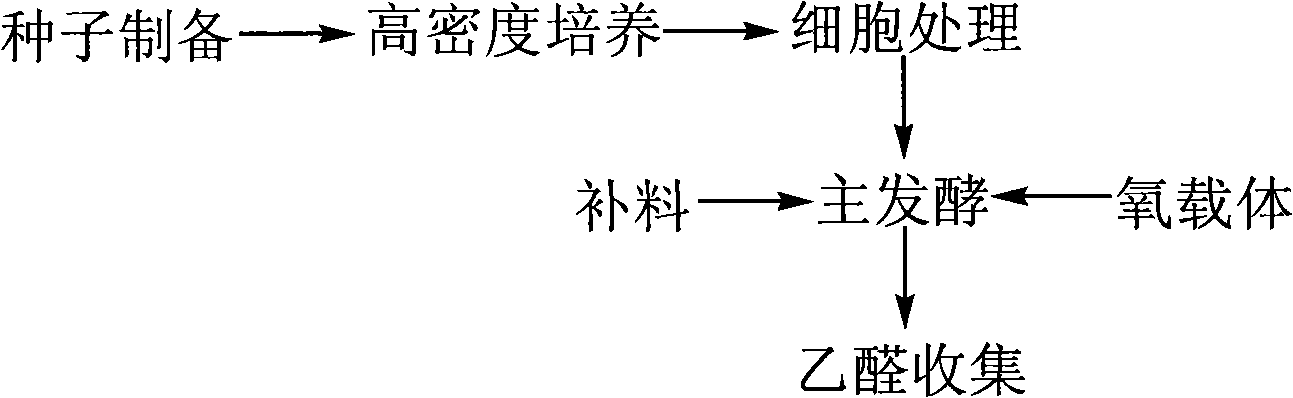

Method used

Image

Examples

Embodiment 1

[0028] Scrape the slanted seeds and inoculate them into 250mL Erlenmeyer flasks filled with liquid medium, each containing 50mL of medium. Seed medium (g / 100mL) consists of glucose: 4, yeast extract: 0.5, potassium dihydrogen phosphate: 0.1, ammonium sulfate: 0.1, magnesium sulfate: 0.05, agar: 2 (for solid medium, liquid seed medium Not added), pH: 7. After the medium is prepared, it is sterilized at 121°C for 20 minutes, cooled and then inoculated. Place the inoculated Erlenmeyer flask on a constant temperature shaker at 25° C., and vibrate at 220 rpm for 48 hours to obtain liquid seeds.

Embodiment 2

[0030] Configure a high-density fermentation medium (g / L), and its composition is as follows: glucose: 150, yeast extract: 10, peptone: 10, ammonium sulfate: 1, potassium dihydrogen phosphate: 1, magnesium sulfate: 1, pH: 7.

[0031] In a 15L full-automatic fermenter, add the above culture medium according to the filling volume of 70% (v / v), and cool to about 25° C. after steam sterilization. Insert the cultured liquid seeds according to the inoculum amount of 5%, carry out aerobic cultivation at a temperature of 25° C. and a stirring speed of 150 rpm, so that the dissolved oxygen level of the fermentation liquid in the tank fluctuates between 30% and 35%. The residual sugar content was detected every 6 hours. When the residual sugar concentration was lower than 5g / L, feed was carried out. After 2 feeds, the wet weight of the cells reached 14.3g / L. At this time, the tank was selected.

Embodiment 3

[0033] Evenly disperse the wet cells obtained by centrifugation in PBS buffer solution with a concentration of 0.2mol / L and a pH of 7.5 to make a 20g / L bacterial suspension, and add hydrogen peroxide at a volume ratio of 1:6 at 25°C Immediately after 10 minutes of solution treatment, the hydrogen peroxide-containing mixture was inoculated.

[0034]In a 100L fermenter, add a 60% (v / v) liquid volume to the fermentation medium, and its composition (g / L) is: glucose: 100, yeast extract: 10, ammonium sulfate: 1, potassium dihydrogen phosphate : 1, magnesium sulfate: 0.5, pH: 7, steam sterilized and cooled to 30°C. Pasteurized n-dodecane was added in a ratio of 2% (v / v), the stirring speed was 150 rpm, and the mixture was thoroughly mixed for 15 minutes. Insert the above-mentioned cell fluid treated with hydrogen peroxide at an inoculum amount of 5% (v / v), control the temperature at 30°C, and ventilate at 0.2v / v.min. The stirring speed is automatically controlled within 500rpm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com