Easy-cutting antimony-zinc alloy and preparation method of bar thereof

An aluminum alloy and easy-cutting technology, which is applied in the field of preparation of antimony zinc aluminum alloy and its bars, achieves the effects of good cutting performance, easy processing and improved machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 87.00wt% of zinc, 10.00wt% of aluminum and 3.00wt% of antimony were uniformly mixed, and a master alloy billet with a diameter of 170 mm was produced by semi-continuous casting. Then it is hot-extruded into a rod blank at a temperature of 300°C, and then a rod with a required diameter is made by a combined drawing method. After measurement, the tensile strength of the rod is 320 MPa, the elongation is 12%, and the hardness is HB=85. The bar is drilled into parts with a cam-type automatic lathe, and the chips are fragile, and the efficiency can reach 90% of that of C3604 lead brass rods; at the same time, the surface of the parts can be nickel-plated, chrome-plated, tin-plated and other surface treatments as required.

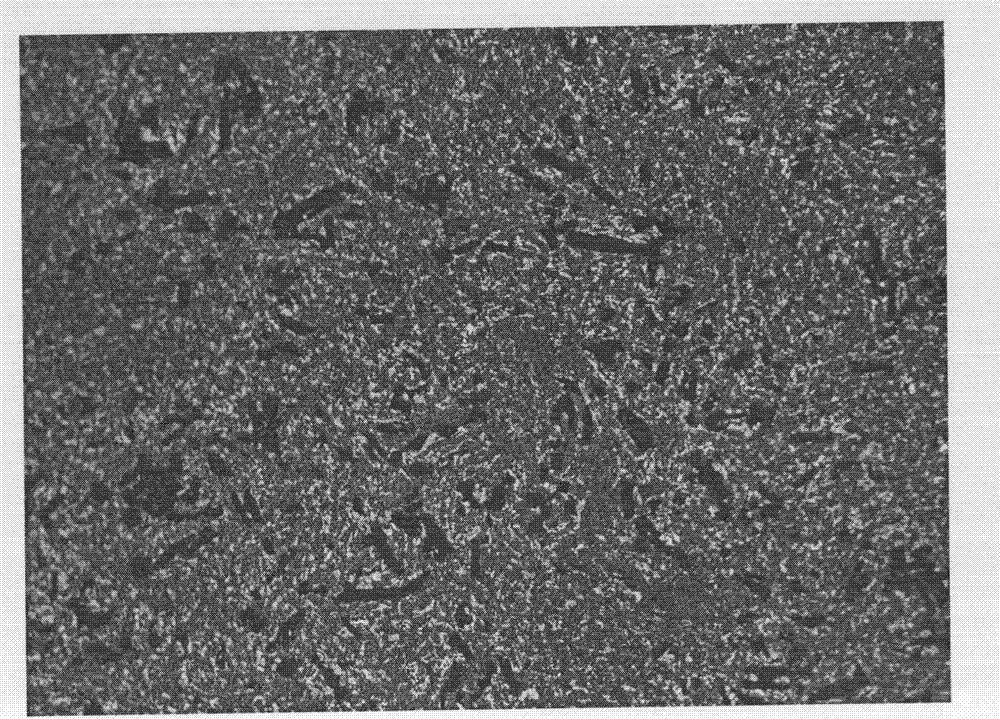

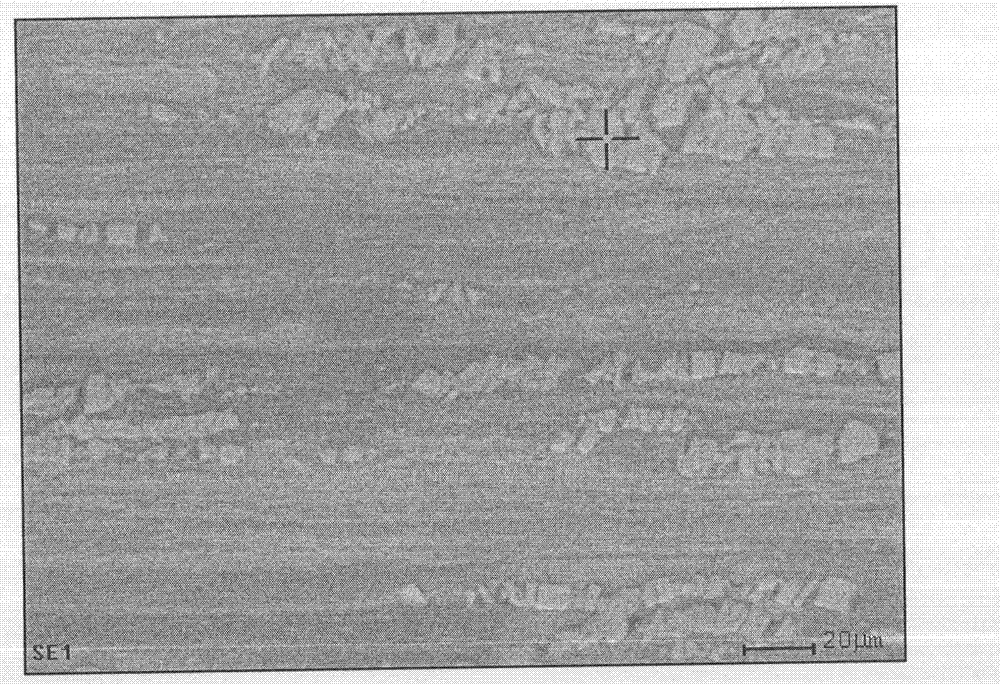

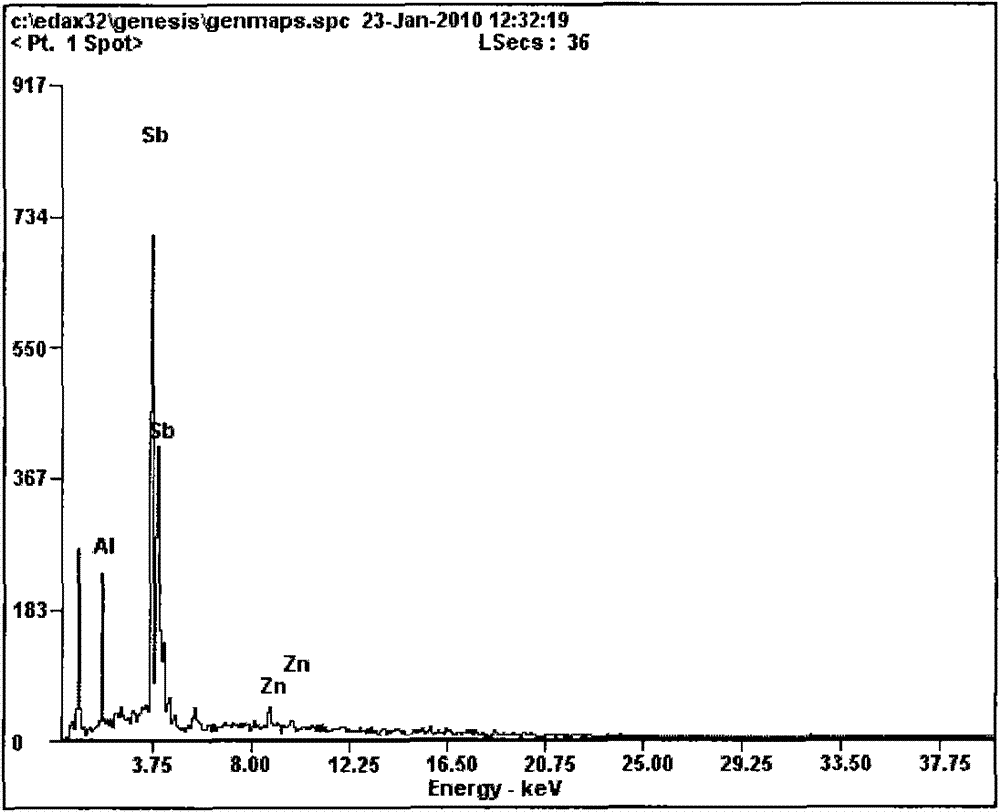

[0024] figure 1 It is the 500 times metallographic diagram of the master alloy billet in the state of hot extrusion at 300 °C. figure 1 The black structure in is the intermetallic compound phase AlSb. AlSb has an irregular shape and a micron-scale si...

Embodiment 2

[0029] 83.00wt% of zinc, 15.00wt% of aluminum and 2.00wt% of antimony are evenly mixed, the alloy is smelted by induction heating, and the alloy cast billet is made by die casting. Then the cast slab is extruded into a bar billet at a temperature of 200°C, and a zinc alloy bar is made by a crawler broaching machine. The measured tensile strength of the bar is 380Mpa, and the elongation is 15%. After polishing and straightening, electronic products are processed on CNC machine tools, and its processing efficiency can reach 85% of that of C3604 lead brass rods. The surface of the parts can be treated with nickel plating, chrome plating, tin plating, etc.

Embodiment 3

[0031] Mix 91.00wt% of zinc, 1.00wt% of aluminum, and 8.00wt% of antimony evenly, melt by induction heating, and use steel mold casting to obtain a master alloy billet, which is extruded into an alloy at 180°C The blank of the bar is passed through the multi-die wire drawing machine to the size before the finished product, and then the finished product is obtained after combined drawing reduction, straightening and polishing. The finished product is processed by a cam type automatic lathe, and the processing efficiency can reach 90% of that of C3604 lead brass of the same specification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com