Ultra-fine cone electrode array and method for manufacturing same

A technology of electrode arrays and ultra-micro electrodes, which is applied in the field of micro-sensing, can solve the problems of affecting the range of use of ultra-micro electrode arrays, lack of wide-scale promotion and application, and high cost, so as to reduce the difficulty of preparation, increase the aspect ratio, and reduce the cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

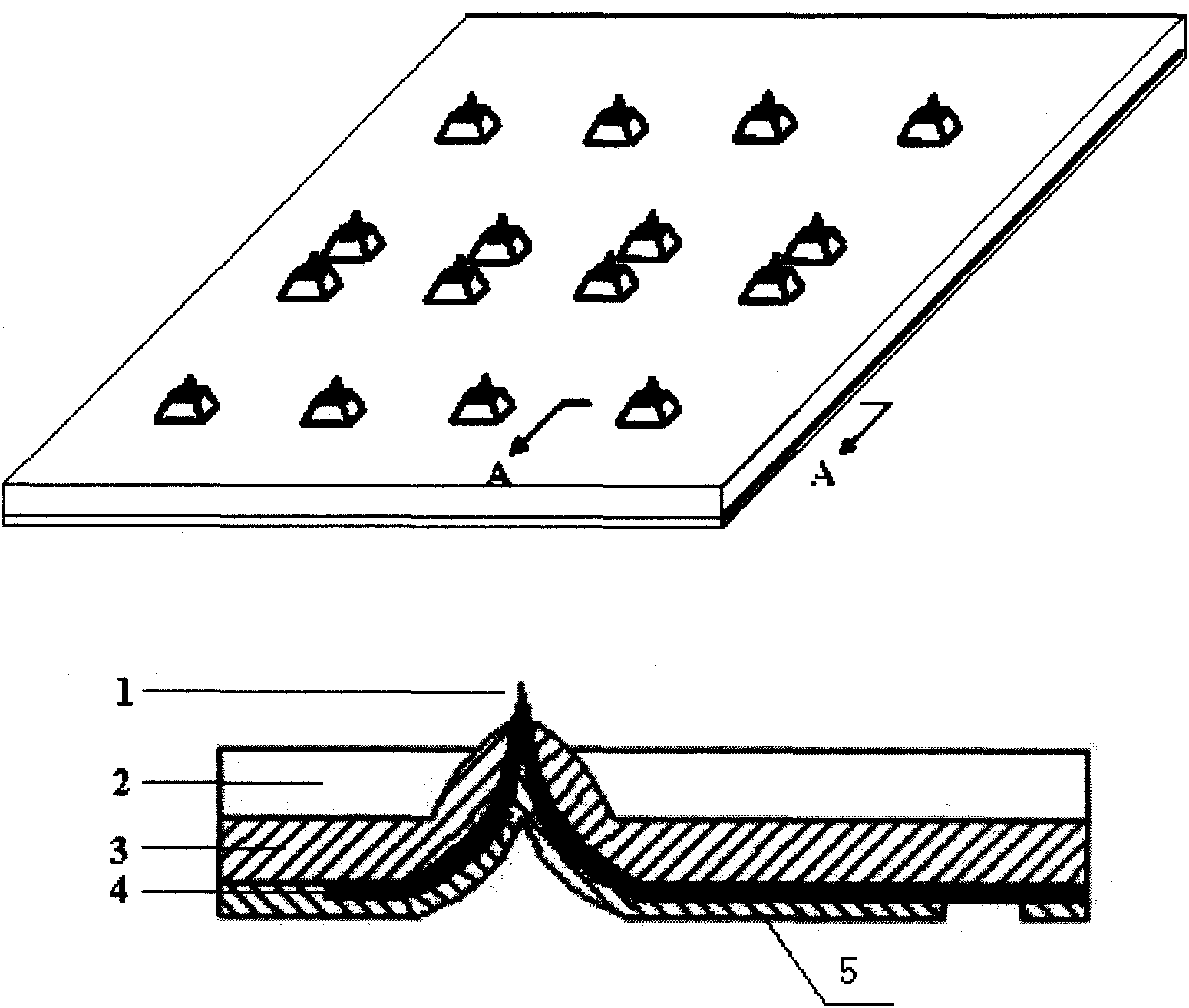

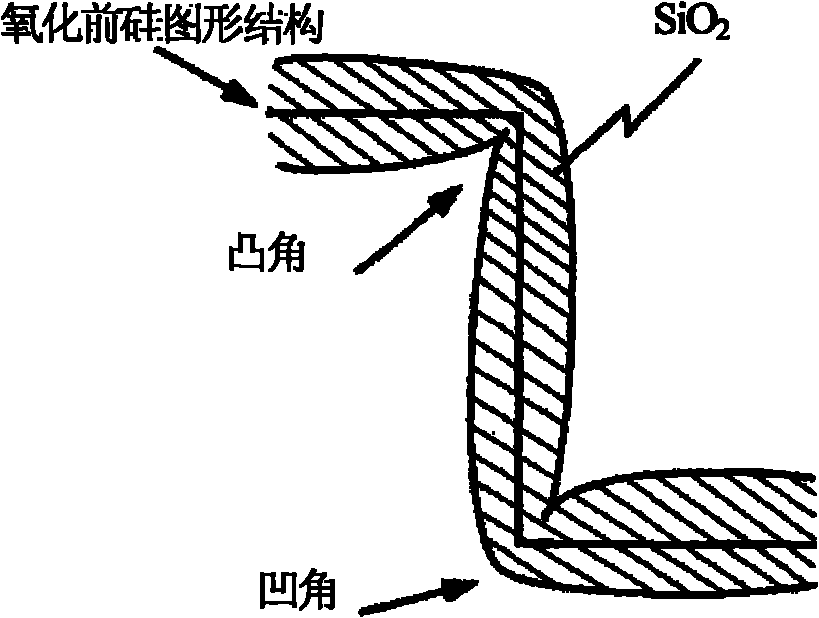

[0040] see figure 1 , the ultra-micro-cone electrode array of the present invention includes a single-sided polished silicon wafer 2 as a substrate, and the single-sided polished silicon wafer adopts p-Si (100) with a resistivity of 0.01-0.1Ω·cm, and the thickness of the substrate is 200 μm , and several groups of regular pyramidal pits with a taper angle of 70.52° in the silicon wafer 2, and a layer of SiO with inconsistent thickness covering the silicon wafer 2 and the regular quadrangular pyramidal pits 2 Thin film 3, on SiO 2 A layer of 400nm and patterned conductive metal film electrode material layer 4 is provided on the surface of the film 3, and a 700nm and patterned Si layer is provided on the conductive metal film electrode material layer 4. 3 N 4 protective film5.

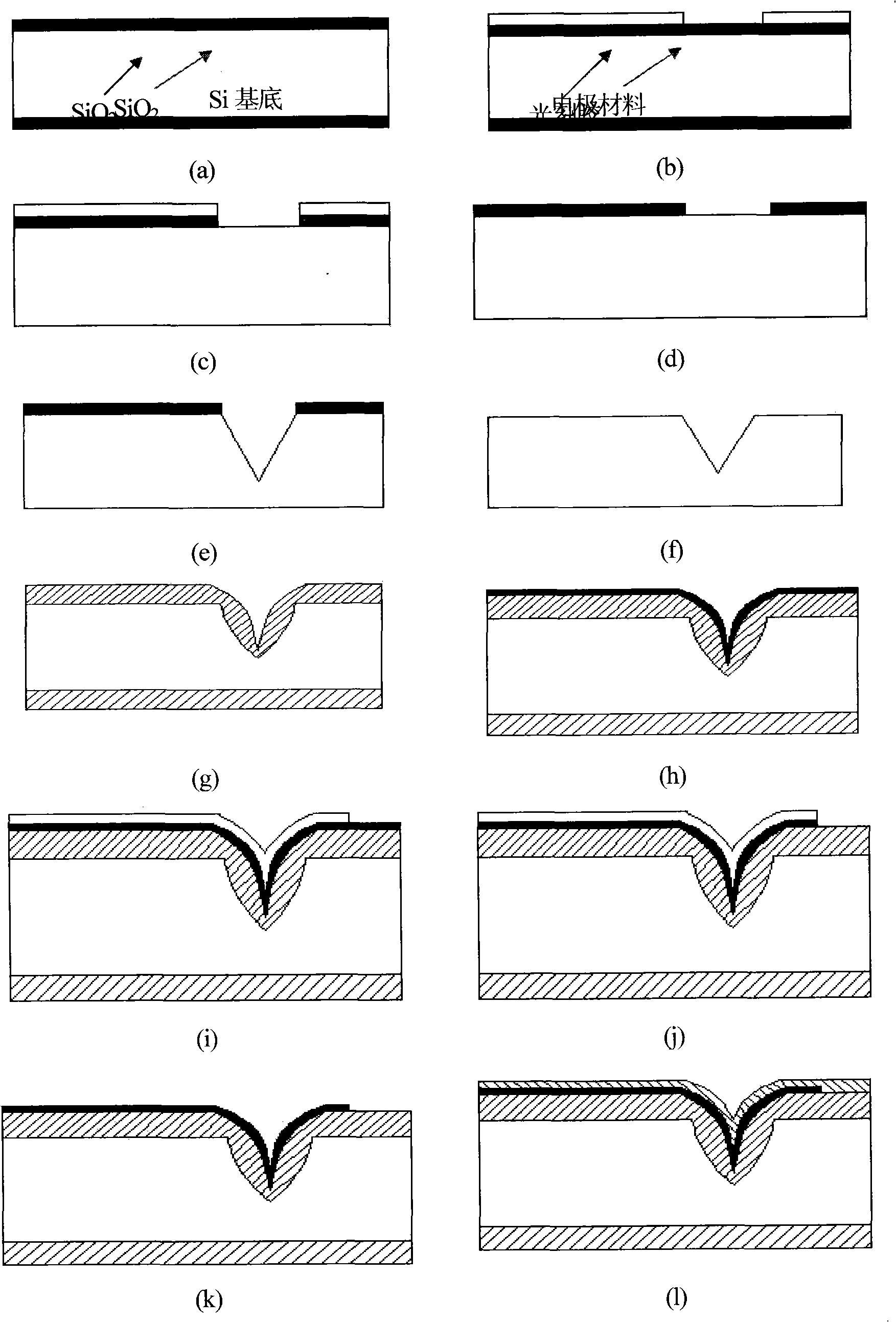

[0041] The manufacture process of the present invention sees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com