Method for preparing metal surface laser strengthened coat

A laser strengthening, metal surface technology, applied in the direction of metal material coating process, coating, etc., can solve problems such as affecting the interface bonding force, affecting performance, easy to oxidize, etc., to achieve faster carbothermal reaction speed and high utilization rate of raw materials , reduce the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

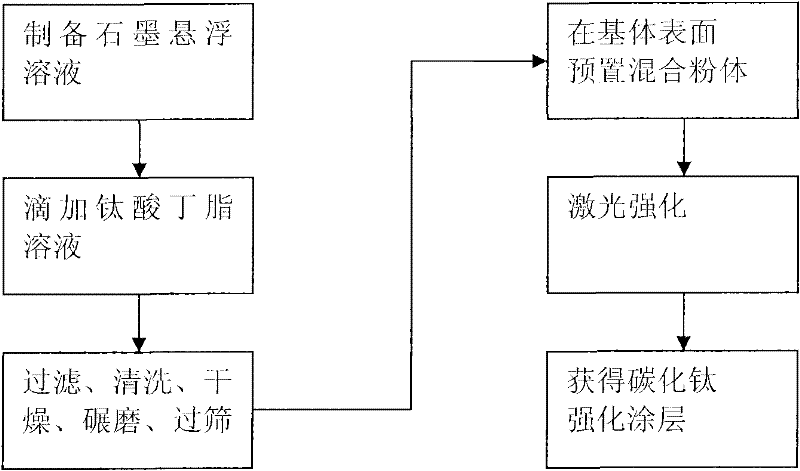

[0038] Such as figure 1 A method for preparing a metal surface laser strengthening coating shown, comprising the steps of:

[0039] (1) Prepare the mixed powder that hydrated titanium dioxide and graphite powder are evenly mixed by wet chemical method;

[0040] (2) Presetting the above-mentioned mixed powder on the surface of the substrate;

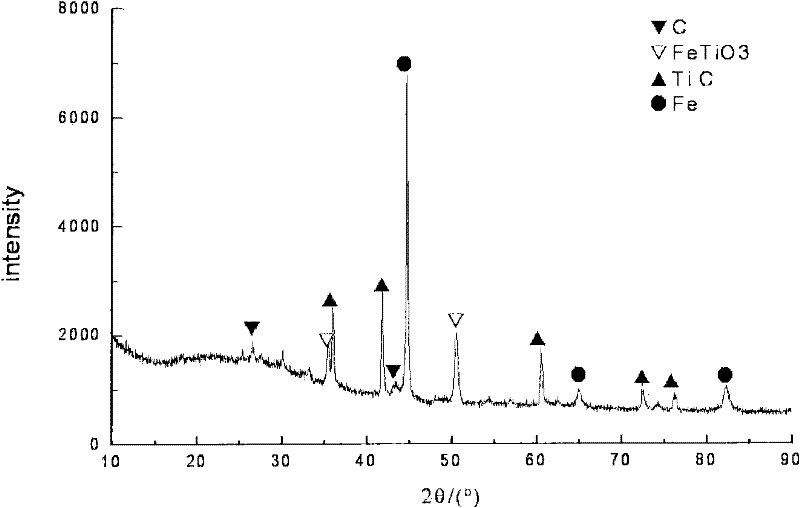

[0041] (3) In an argon atmosphere, the laser is used as a heat source to irradiate the surface of the substrate to form a molten pool. The pre-set mixed powder undergoes a carbothermochemical reaction in a high-temperature environment to form titanium carbide, and finally prepares a dense and uniform surface on the substrate. , Defect-free titanium carbide composite coating.

[0042] Step (1): uniformly mixing hydrated titanium dioxide and graphite powder;

[0043] By hydrolysis of butyl titanate, a precipitate of hydrated titanium dioxide can be obtained. Dissolve butyl titanate in absolute ethanol to prepare a solution of appropriat...

Embodiment 2

[0056] A method for preparing a laser-strengthened coating on a metal surface, comprising the steps of:

[0057] 1. After wetting 2g of graphite with absolute ethanol, add it to 400ml of deionized water, and disperse it with ultrasonic waves for a certain period of time to prevent the agglomeration of graphite particles, so as to obtain a uniformly dispersed suspension of graphite particles.

[0058] 2. Take 10ml of titanium isopropoxide and add it to 100ml of absolute ethanol. After stirring for 15 minutes, add it dropwise to the uniformly dispersed graphite suspension, so that titanium isopropoxide is completely hydrolyzed and evenly attached to the dispersed graphite particles. ((the molar ratio of titanium dioxide to graphite is 1:5), continue to stir vigorously and then filter, first wash the filtrate with deionized water to remove impurities, then wash twice with absolute ethanol, then place the filtrate at 70°C Bake for 8 hours, grind and sieve.

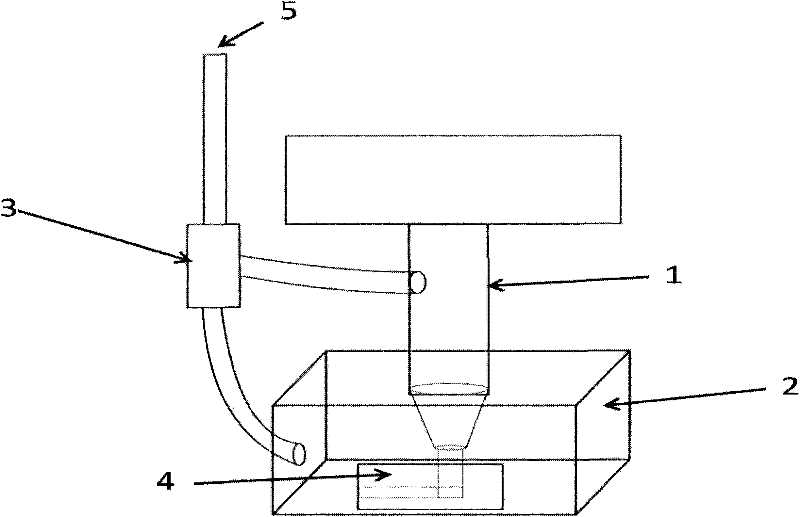

[0059] 3. To degrease...

Embodiment 3

[0062] A method for preparing a laser-strengthened coating on a metal surface, comprising the steps of:

[0063] (1) Prepare the mixed powder that hydrated titanium dioxide and graphite powder are evenly mixed by wet chemical method;

[0064] (2) Mix the above-mentioned mixed powder and urea with deionized water evenly, and preset them on the surface of the substrate;

[0065](3) In a nitrogen atmosphere, the laser is used as a heat source to irradiate the surface of the substrate to form a molten pool, and the preset mixed powder and urea undergo a carbothermal reduction and nitriding reaction in a high-temperature environment to form titanium nitride, which is finally formed on the surface of the substrate. A composite strengthening phase coating of titanium nitride and titanium carbide is prepared.

[0066] Concrete preparation process is as follows:

[0067] 1. After wetting 2g of graphite with absolute ethanol, add it to 400ml of deionized water, and disperse it with ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com