Clean production method of coproduced biologic protein feed of diosgenin

A technology of biological protein feed and diosgenin, applied in animal feed, animal feed, application, etc., can solve the problems of low concentration of sugar solution, large amount of waste water, high production cost of dehydration and concentration, and achieve high sugar yield and no production environment Harmful, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

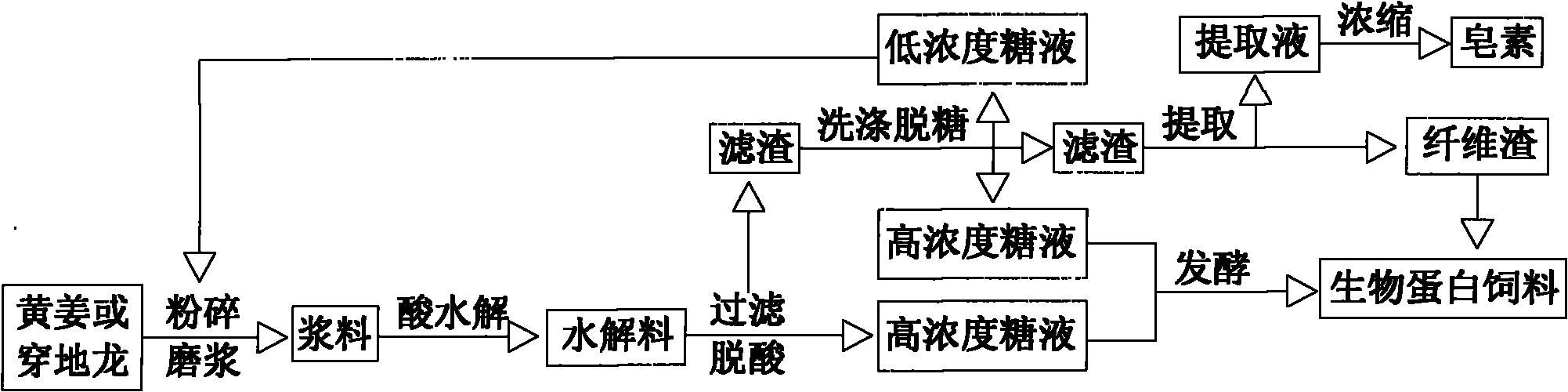

[0038] Embodiment 1: Clean production method of diosgenin co-production biological protein feed

[0039] Take fresh turmeric, wash it with water to remove the surface sediment, crush it with a crusher, add an appropriate amount of water through a colloid mill, refine it to 60 mesh, put it in a hydrolysis tank, add concentrated sulfuric acid to a concentration of 2.5N, pressurize and hydrolyze it in a conventional manner, and put it into a hydrolysis tank. Put it into the filter press cleaner with screen and stirring, add the filtrate to the neutralizer, add calcium carbonate to adjust to pH6-7, filter, put the filtrate into the filter press cleaner, stir and wash the filter residue to deacidify, press filter, and the filtrate Add a neutralizer, add calcium carbonate to adjust to pH6-7, filter, put the filtrate into a filter press cleaner to stir and wash the filter residue to deacidify, then circulate to the filter press cleaner outlet pH6-7, press dry with compressed air, and ...

Embodiment 2

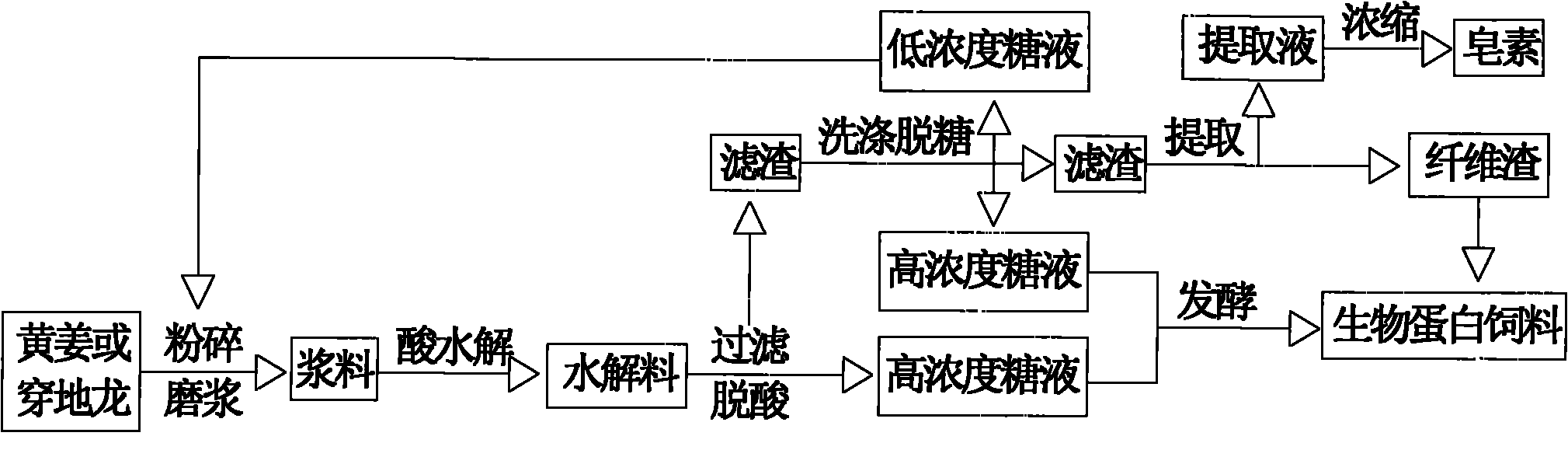

[0040] Embodiment 2: Clean production method of diosgenin co-production biological protein feed

[0041]Take fresh turmeric, wash it with water to remove the surface sediment, crush it with a crusher, add an appropriate amount of water through a colloid mill, refine it to 80 mesh, put it in a hydrolysis tank, add concentrated sulfuric acid to a concentration of 2N, and hydrolyze under pressure in a conventional manner, put Press filter in the filter press cleaner with screen and stirring, add the filtrate to the neutralizer, add calcium carbonate to adjust the pH to 7, filter, put the filtrate into the filter press cleaner, stir and wash the filter residue to deacidify, press filter, add the filtrate to neutralize add calcium carbonate to adjust the pH to 7, filter, and put the filtrate into a filter press cleaner to stir and wash the filter residue for deacidification, so circulate to the filter press cleaner outlet liquid pH7, press dry with compressed air, and obtain a 17% s...

Embodiment 3

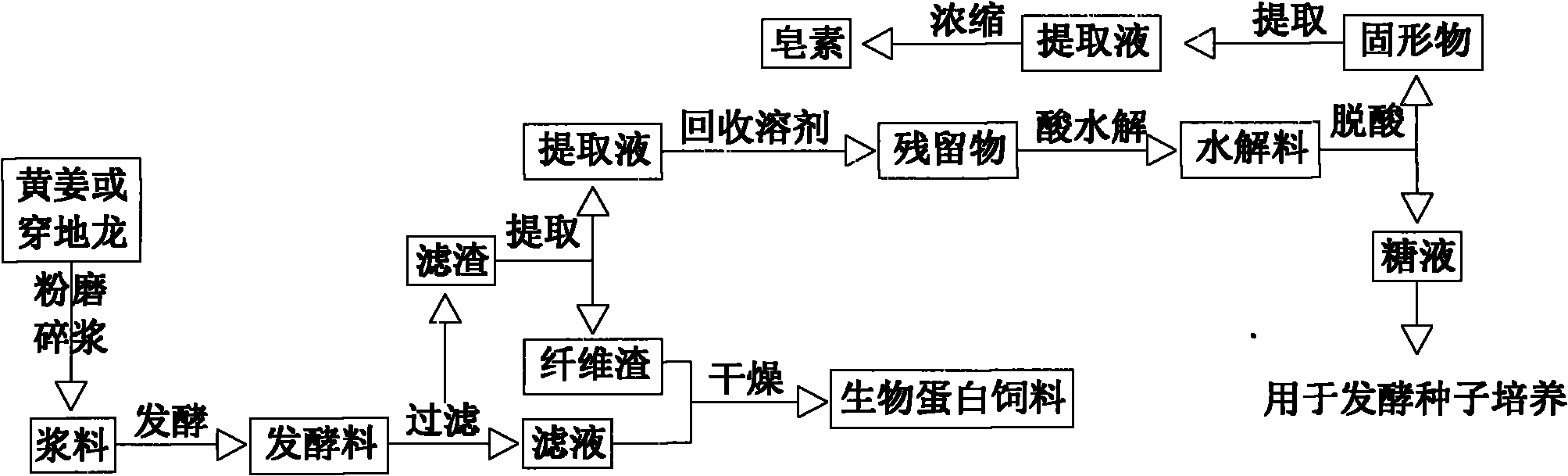

[0042] Embodiment 3: the clean production method of diosgenin co-production biological protein feed

[0043] Take fresh turmeric, wash it with water to remove the surface sediment, crush it with a crusher, add water to the colloid mill to refine it to 60 mesh, measure the sugar content to 20%, add other auxiliary materials to make the mother liquid sugar 10%, urea 0.7%, bean cake Powder 3%, potassium dihydrogen phosphate 0.08%, corn steep liquor 0.09%, sodium chloride 0.4%, aseptic inoculation of yeast seeds, inoculum size: 30%, at 40°C, under a sterile environment, aeration and stirring for 72 hours, Until the fermentation broth has no starch reaction and the sugar concentration in the water is lower than 0.5%, the fermented material is obtained, and the fermented material is press-filtered to obtain the filtrate and filter residue respectively. The filter residue is extracted with alcohol or acetone, and the extracted residue is combined into the filtrate and dried to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com