Preparation method of soft segment lateral chain fluorine-containing waterborne polyurethane

A technology of water-based polyurethane and fluorine-containing polyether, which is applied in the field of surface coating, can solve the problems of low yield and slow synthesis reaction, and achieve the effects of low odor, reduced surface tension and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of soft segment side chain fluorine-containing water-based polyurethane of the present invention is prepared by self-made fluorine-containing polyether diol, and the production formula is composed of the following component proportions (parts by weight):

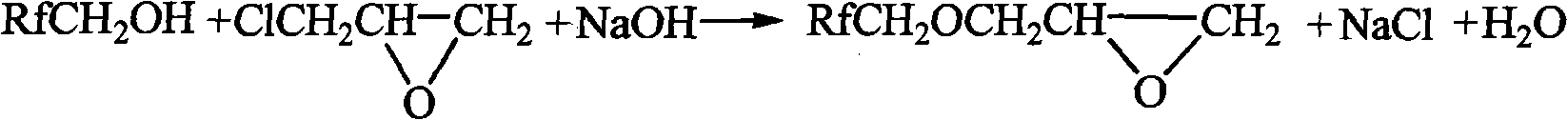

[0024] (1) Synthesis of fluorine-containing glycidyl ether: Add 22 parts of epichlorohydrin and 8 parts of sodium hydroxide into a three-necked flask, heat and stir at high speed, and slowly add octafluoropentanol 46 at 40-60°C part, continue to react for 2-3h; stop the reaction, remove the sodium chloride generated by the reaction by suction filtration, and remove the epoxy compound by distillation under reduced pressure to obtain fluorine-containing glycidyl ether; its reaction formula is

[0025]

[0026] Among them, Rf=H(CF 2 ) 6 , H(CF 2 ) 4 , or H(CF 2 ) 2 ;

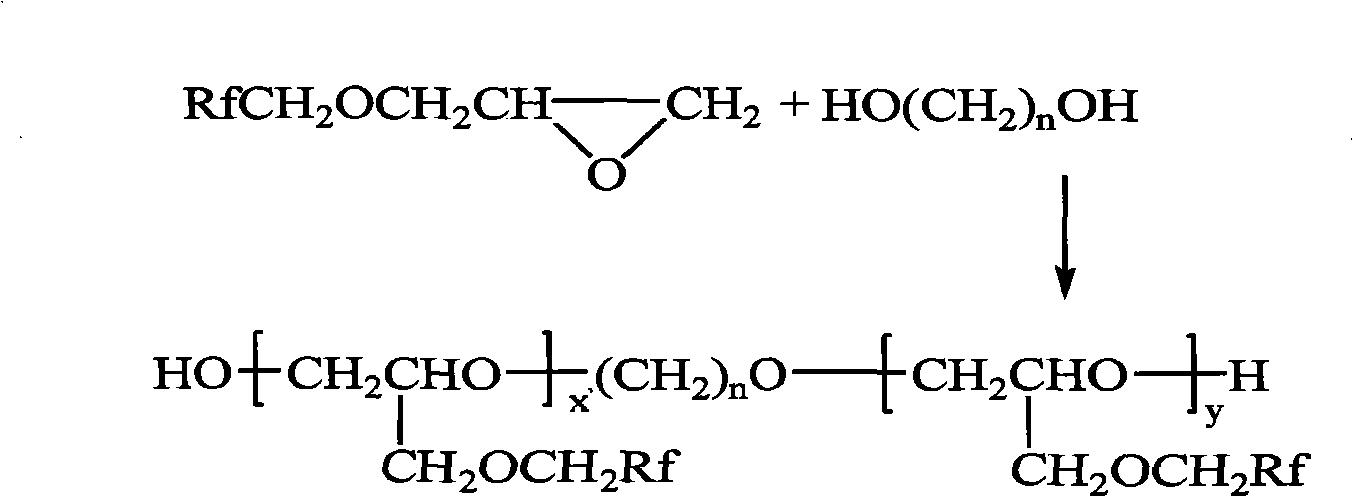

[0027] (2) Synthesis of side chain fluorine-containing polyether glycol (PFGE)

[0028] Add measured 0.18 parts of 1,4-butanediol, 0.28 p...

Embodiment 2

[0036] On the basis of the above steps (1) (2), take 60 parts of toluene diisocyanate (IPDI), 50 parts of fluorine-containing polyether glycol (PFGE), 50 parts of polybutylene adipate, and 0.02 parts of catalyst , 10 parts of dimethylolpropionic acid (DMPA), 350 parts of water.

[0037] The water-based polyurethane of the above formula is produced by the following preparation method, reacting fluorine-containing polyether glycol (PFGE), polybutylene adipate, DMPA, IPDI and catalyst at 80-85°C for 5-8h, and cooling to 40°C ℃, add neutralizing agent to react for 30 minutes, add water to disperse for 30 minutes, and then discharge.

[0038] The emulsion properties of this product are as follows:

[0039]

[0040] The film characteristics of this product are as follows:

[0041]

[0042]

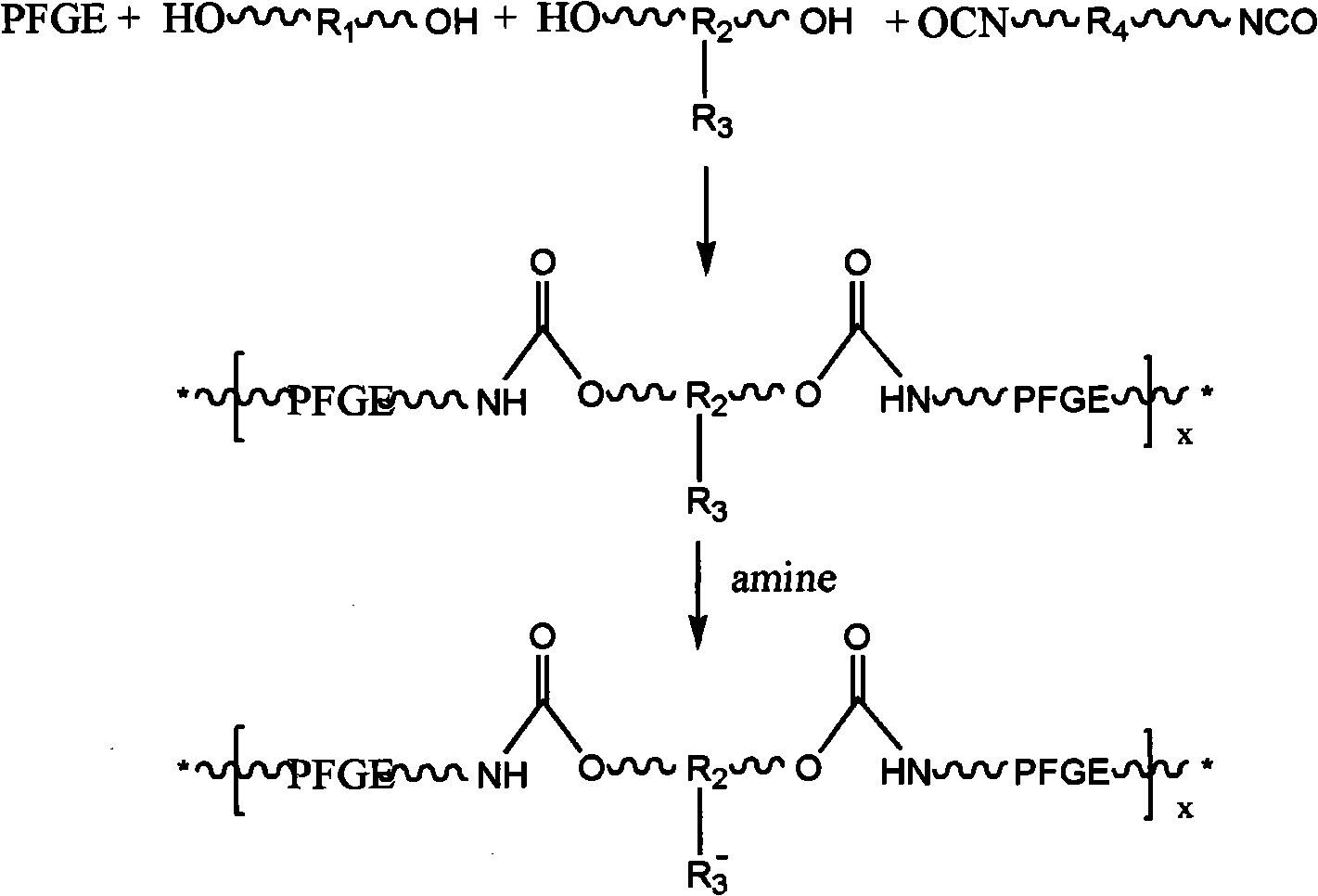

[0043] Among them, HO-R 1 -OH is the general formula of polyester diol, HO-R 2 (R 3 )-OH is a hydrophilic chain extender, R 3 - for-COO - Anionic hydrophilic group, OCN-R 4 -NC...

Embodiment 3

[0049] On the basis of the above steps (1) (2), take 60 parts of toluene diisocyanate (TDI), 80 parts of fluorine-containing polyether glycol (PFGE), 20 parts of polybutylene adipate, and 0.02 parts of catalyst , 10 parts of dimethylolpropionic acid (DMPA), 350 parts of water.

[0050] The water-based polyurethane of the above formula is produced by the following preparation method, reacting fluorine-containing polyether glycol (PFGE), polybutylene adipate, DMPA, TDI and catalyst at 80-85°C for 5-8h, cooling to 40°C ℃, add neutralizing agent to react for 30 minutes, add water to disperse for 30 minutes, and then discharge.

[0051] The emulsion properties of this product are as follows:

[0052]

[0053] The film characteristics of this product are as follows:

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com