Method for synthesizing fluorine-silicon-oxygen polymer body through anion ring-opening polymerization and reactive extrusion

An anionic ring-opening and polymerization technology, which is applied in the field of polymer polymerization, can solve the problems that the initiator system cannot respond to the use of extrusion technology, and achieve the effect of good industrialization prospects, high quality and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

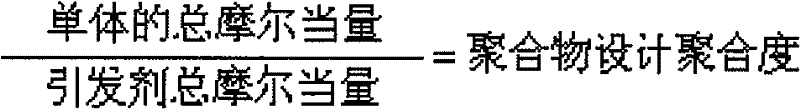

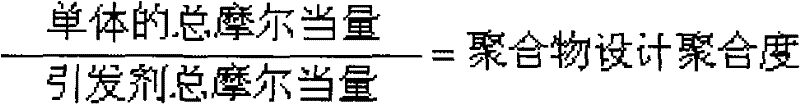

Method used

Image

Examples

Embodiment 1

[0030] The trifluoropropyltrimethylcyclotrisiloxane monomer that has been purified to meet the polymerization requirements of the present invention is heated to 35-40°C. The mass ratio of trifluoropropyltrimethylcyclotrisiloxane / sodium hydroxide is 50:1, protected by argon, and prepolymerized at 120°C for 30 minutes to prepare the sodium silanolate initiator, and according to the volume ratio of 20 / 3 Add trifluoropropyltrimethylcyclotrisiloxane to dilute the initiator. There are 5 feed inlets on the twin-screw extruder, which are respectively located in the first, second, third, fourth, and eighth barrel sections, which are the feed inlets for the above-mentioned monomers in turn, and the accelerator dimethyl sulfoxide Feed inlet, sodium silanolate initiator feed inlet, methyl vinyl cyclotetrasiloxane feed inlet, chloropentamethyldisiloxane feed inlet; under the delivery of metering pump, the refined The monomer, accelerator, and initiator are input into the twin-screw extrud...

Embodiment 2

[0035] The trifluoropropyltrimethylcyclotrisiloxane monomer that has been purified to meet the polymerization requirements of the present invention is heated to 35-40°C. The mass ratio of trifluoropropyltrimethylcyclotrisiloxane / sodium hydroxide is 50:1, protected by argon, and prepolymerized at 120°C for 30 minutes to prepare the sodium silanolate initiator, and according to the volume ratio of 20 / 3 Add trifluoropropyltrimethylcyclotrisiloxane to dilute the initiator. There are 5 feeding ports on the twin-screw extruder, which are respectively located in the first, second, third, fifth, and eighth screw barrel sections, which are the above-mentioned monomer feeding ports in turn, and the accelerator ethyl acetate feed Inlet, sodium silanolate initiator inlet, hexamethylcyclotrisiloxane and methylvinylcyclotetrasiloxane mixed monomer inlet, trimethylchlorosilane inlet; delivery in metering pump Next, the refined monomers, accelerators, and initiators are input into the twin-s...

Embodiment 3

[0040] Heating the mixed monomers of trifluoropropyltrimethylcyclotrisiloxane and octamethylcyclotetrasiloxane in an equimolar ratio required by the polymerization of the present invention to 35-40°C. The mass ratio of trifluoropropyltrimethylcyclotrisiloxane / sodium hydroxide is 50:1, protected by argon, and prepolymerized at 120°C for 30 minutes to prepare the sodium silanolate initiator, and according to the volume ratio of 20 / 3 Add trifluoropropyltrimethylcyclotrisiloxane to dilute the initiator. There are 4 feed inlets on the twin-screw extruder, which are respectively located in the first, second, third, fourth, and eighth screw barrel sections, which are the feed inlets for the above-mentioned mixed monomers in turn, and the accelerator ethyl acetate feed inlet. Feed port, sodium silanolate initiator feed port, methyl vinyl cyclotetrasiloxane feed port, chloropentamethyldisiloxane feed port; under the delivery of the metering pump, the refined single The body, accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com