Phosphorus-containing hydroquinone derivative, phosphorus-containing flame-retardant epoxy resin, preparation method and application thereof

A technology of hydroquinone and derivatives, which is applied in the field of phosphorus-containing flame-retardant epoxy resin and its preparation, and can solve problems such as reduced heat resistance, high heat release, and the influence of processing effect on the final state dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

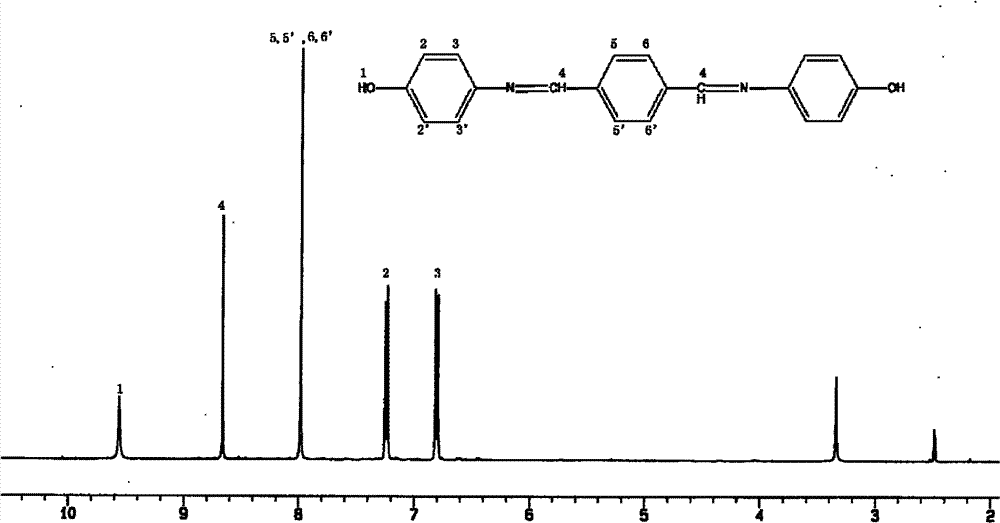

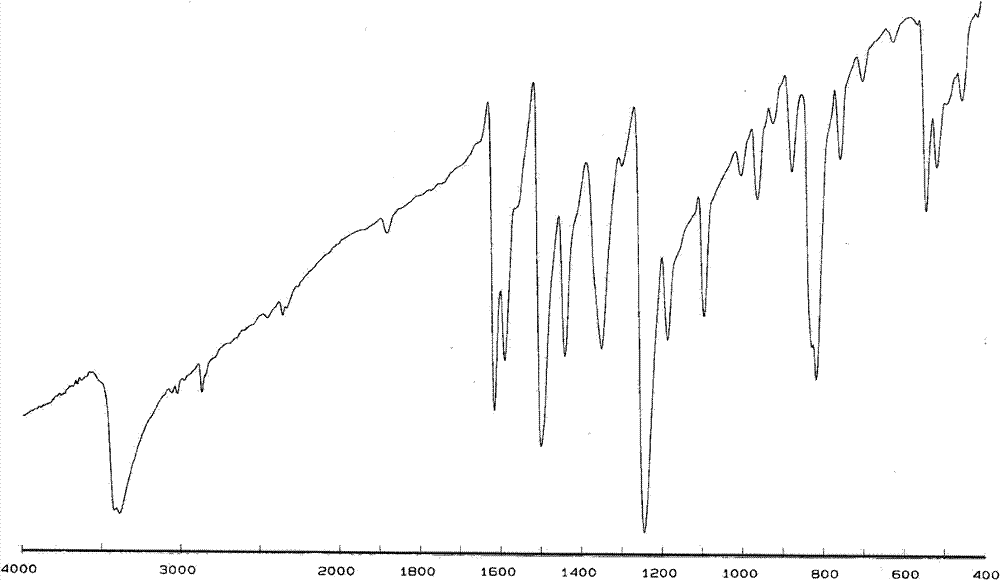

[0077] (1) With N 2 Pass into the reaction flask of device, stirring device, thermometer, condensate pipe, add 20g terephthalaldehyde, 30g p-aminophenol, and dissolve in the mixing of DMSO and ethanol (EtOH) (DMSO:EtOH=1:2 volume ratio) In the solvent, add 0.6g ZnCl 2as a catalyst. The reaction was heated to 80°C, stirred and refluxed for 3 hours, and cooled to room temperature, a large number of yellow crystals precipitated. Suction filtration, washed 3 times with deionized water, placed in a vacuum oven, dried at 75°C for 24 hours, and the product obtained was recrystallized with a mixed solvent of ethanol / DMSO (8:1) to obtain 46g of Phenolic hydroxyl group, imine dihydric phenol substance BP-1 with Schiff base structure on the skeleton. pass 1 H NMR and FT-IR detection methods, the chemical structure of the synthesized compound BP-1 has been relatively clearly characterized, and the results are respectively figure 1 with figure 2 shown.

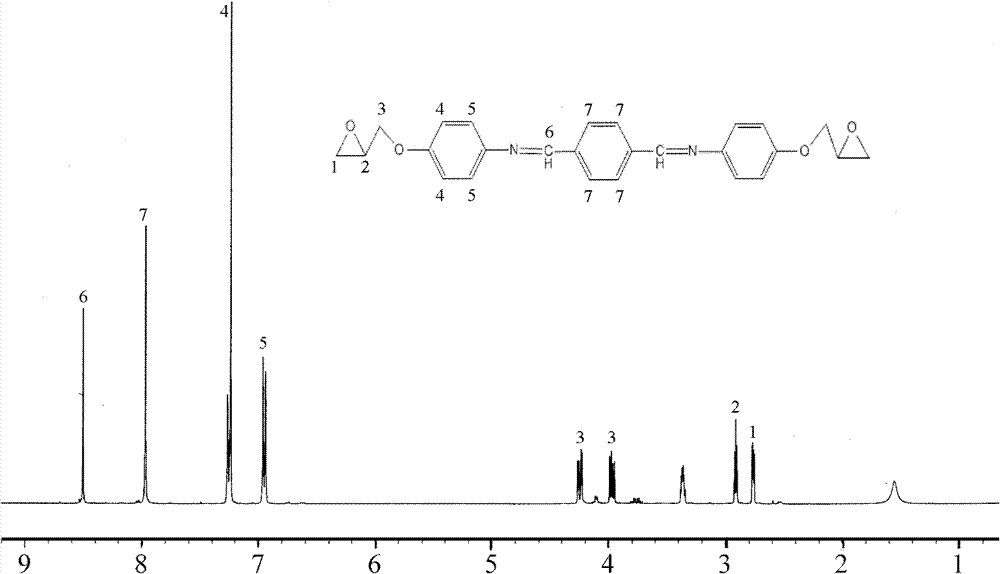

[0078] (2) Add 31.6g BP-1, ...

Embodiment 2

[0080] (1) With N 2 Pass into the reaction flask of device, stirring device, thermometer, condensate pipe, add 20g terephthalaldehyde, 30g p-aminophenol, and dissolve in the mixing of DMSO and ethanol (EtOH) (DMSO:EtOH=1:2 volume ratio) In the solvent, add 0.6g ZnCl 2 as a catalyst. The reaction was heated to 80°C, stirred and refluxed for 3 hours, and cooled to room temperature, a large number of yellow crystals precipitated. Repeat the operation of Example 1 step (1) to obtain 46g BP-1.

[0081] (2) In another reaction flask equipped with a stirring device, a thermometer, and a condensate pipe, add the BP-145g obtained by the above reaction dissolved in a mixed solvent of ethanol and DMSO (DMSO:EtOH=1:2 volume ratio), heat to 75°C, stir, dissolve, add 0.7g ZnCl 2 as a catalyst. In thru dry N 2 Under the protection of , began to slowly drop 50g diethyl phosphite, and the dropwise addition was completed in 2 hours. Then the temperature was raised to 90°C, and the reacti...

Embodiment 3

[0084] According to the epoxy equivalent value of the epoxy resin, weigh them respectively according to the equimolar stoichiometric ratio (1:1): Group A: 296.8 mg of the imine epoxy resin containing the Schiff base structure on the skeleton obtained in Example 1 Monomer EP-1 and 68.8mg curing agent 4,4'-diaminodiphenylmethane (MDA); B group: phosphorus-containing flame-retardant epoxy monomer EP-2 and 31.7mg obtained in 225.2mg embodiment 2 Curing agent 4,4'-diaminodiphenylmethane (MDA); Group C: 832.1mg common epoxy resin EPON-828 (DGEBA) and 218.2mg curing agent 4,4'-diaminodiphenylmethane (MDA ). Then use the mixed solvent of acetone and chloroform with a volume ratio of 1:10 as the solvent, stir and mix the groups A, B and C respectively, and remove the solvent under vacuum at room temperature. The obtained mixture was cured at a high temperature in a vacuum oven, and the curing conditions were: 2 hours at 160°C, 2 hours at 180°C, 2 hours at 200°C, and 1 hour at 220°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com