Acrylic pressure-sensitive adhesive sheet

An acrylic, adhesive sheet technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc. and other problems, to achieve the effect of excellent bonding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

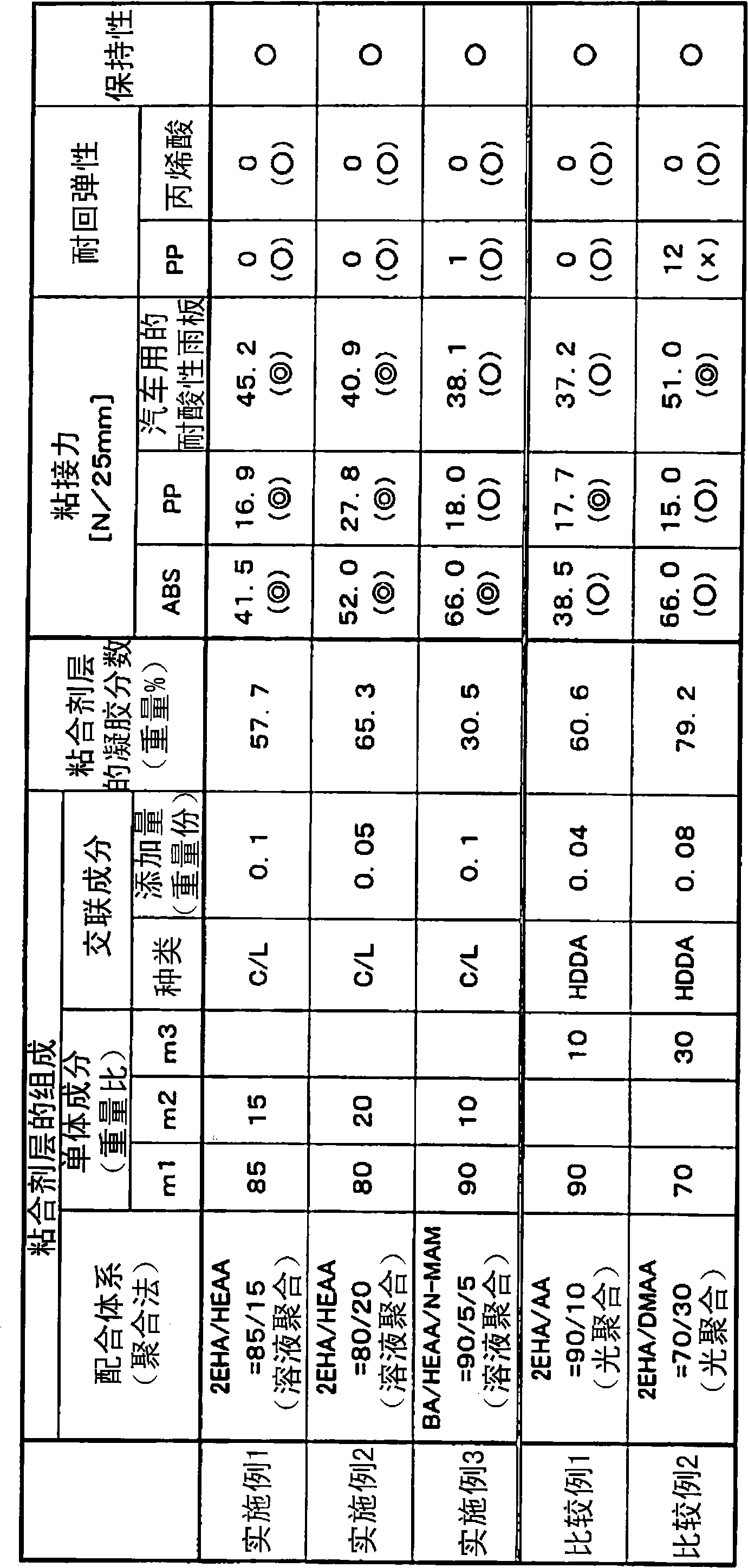

Examples

Embodiment 1

[0176] [Preparation of Viscoelastic Layer (X)]

[0177] As a monomer component, 90 parts by weight of 2-ethylhexyl acrylate and 10 parts by weight of acrylic acid were mixed, and 0.05 parts by weight of a photopolymerization initiator 2,2-dimethoxy-1,2- Diphenylethan-1-one (trade name "Irgacure 651", produced by Ciba Japan K.K.) and 0.05 parts by weight of photopolymerization initiator 1-hydroxy-cyclohexyl-benzophenone (trade name "Irgacure 184", produced by Ciba Japan K.K. production), and then irradiate ultraviolet light until the viscosity (measured under the conditions of BH viscometer, No.5 rotor, 10rpm, and measurement temperature: 30°C) is 15Pa·s, and a part of the polymerized composition ("slurry A ").

[0178] In 100 parts by weight of the above-mentioned slurry A, add 0.1 parts by weight of 1,6-hexanediol diacrylate, and then further add hollow glass spheres (trade name "Cellstar Z-27", which is 30% by volume relative to the total volume of the slurry) Manufactured...

Embodiment 2

[0188] In [Preparation of Adhesive Layer (Y)], 80 parts by weight of the monomer component 2-ethylhexyl acrylate was added to a reaction vessel equipped with a cooling pipe, a nitrogen gas introduction pipe, a thermometer, a dropping funnel, and a stirring blade. (2EHA, Tg of homopolymer: -70°C) and 82 parts by weight of solvent ethyl acetate, and make N-hydroxyethylacrylamide (HEAA, Tg of homopolymer: 98°C) prepared in the dropping funnel 20 parts by weight, 35 parts by weight of ethyl acetate as a solvent, and further 0.05 parts by weight (in terms of solid content) of an isocyanate-based crosslinking agent (trimethylolpropane and toluene diisocyanate) were added to the solution of the obtained acrylic polymer. An acrylic pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that the reaction product was a product named "CORONATEL" Nippon Polyurethane Industry Co., Ltd., C / L).

[0189] In addition, the gel fraction of the pressure-sensitive...

Embodiment 3

[0191] [Preparation of viscoelastic (X)]

[0192] In the same manner as in Example 1, a viscoelastic layer consisting of a release liner / bubble mixed pressure-sensitive adhesive / a viscoelastic layer of a release liner was produced.

[0193] [Preparation of Adhesive Layer (Y)]

[0194] In the reaction vessel equipped with cooling pipe, nitrogen inlet pipe, thermometer, dropping funnel and stirring blade, add 0.1 parts by weight of polymerization initiator 2,2-azobisisobutyronitrile (AIBN), 90 parts by weight of monomer component acrylic acid Butyl ester (BA, Tg of homopolymer: -54° C.) and 82 parts by weight of ethyl acetate as a solvent were stirred at room temperature under a nitrogen atmosphere for 1 hour. Then, the content of the reaction vessel (the solution containing the entire monomer component) was heated to 60°C, and 0.2 parts by weight of the polymerization initiator 2, 2 -Azobisisobutyronitrile (AIBN), 5 parts by weight of N-hydroxyethylacrylamide (HEAA, Tg of hom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com