Cefotetan disodium hydrate and preparation method and application thereof

A technology of cefotetan disodium and hydrate, which is applied in the field of medicine and achieves the effects of good sliding property, improved operability, and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

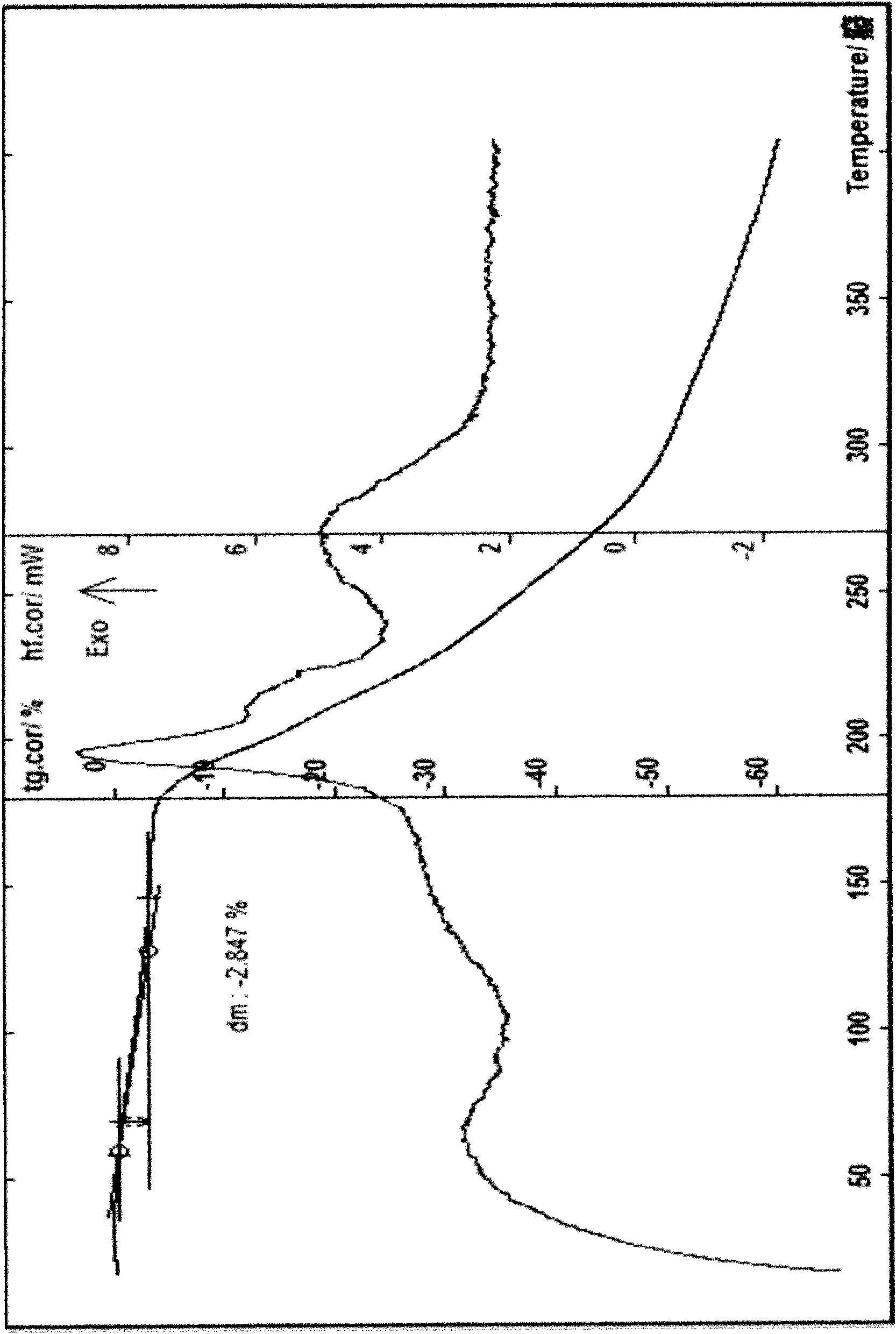

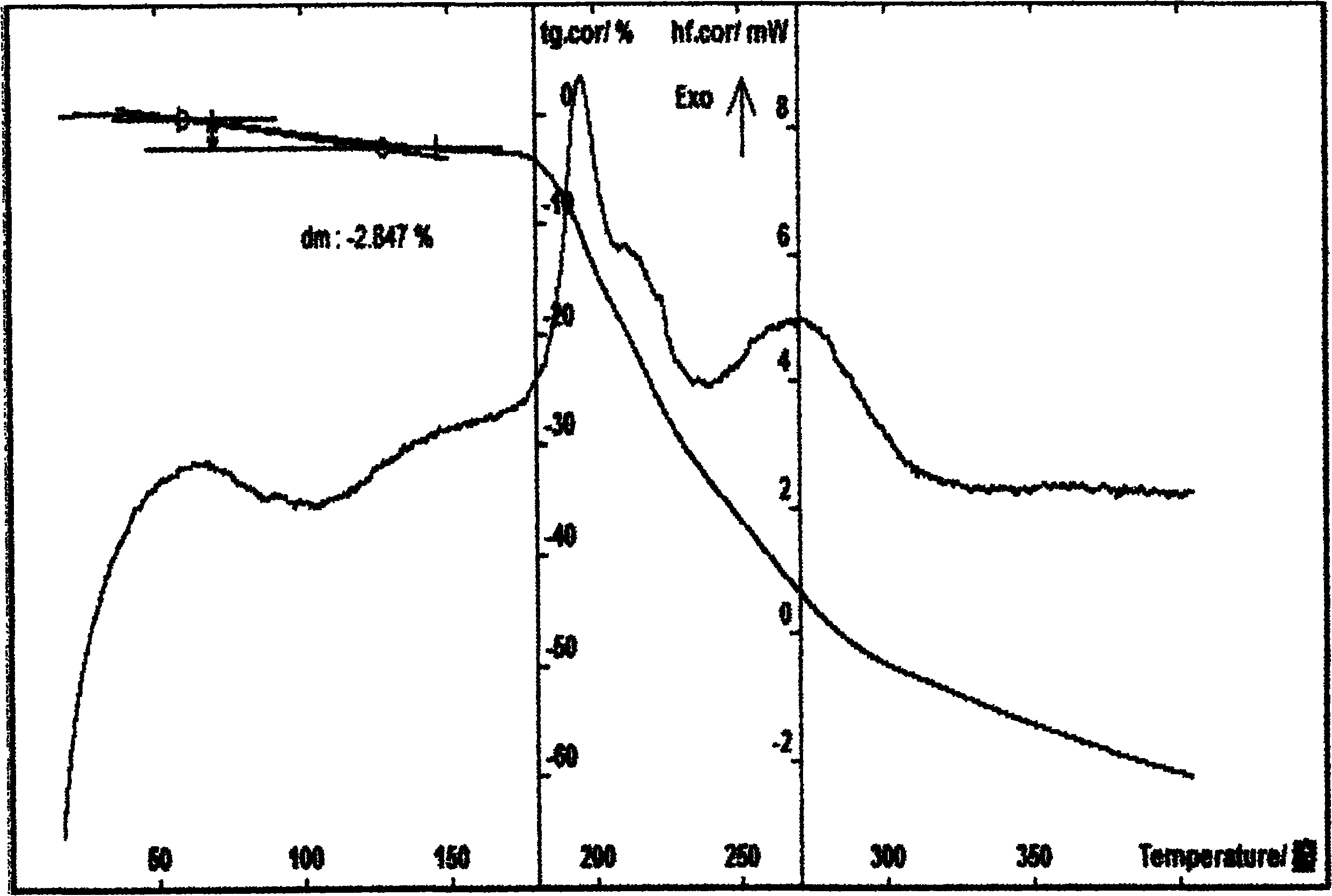

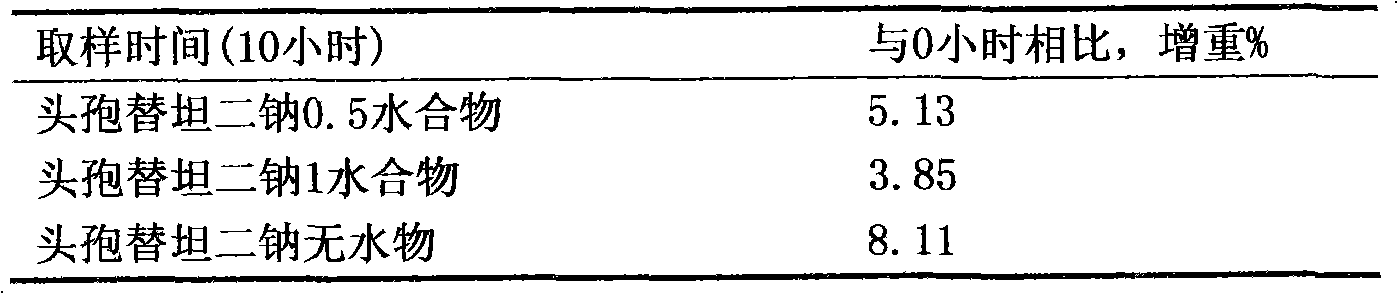

[0037]Example 1 Preparation of Cefotetan Disodium Monohydrate Add 10 g of cefotetan diacid and 50 ml of water into a reaction flask, stir to form a suspension, add triethylamine dropwise at 5° C., and stir to make the pH to 7.5 Add 0.1 g of activated carbon, stir for 30 minutes, filter with suction, wash with water, filter with suction, add dropwise an ethanol solution of 28% sodium isooctanoate (5.81 g) in the filtrate at 5° C., stir for 40 minutes, slowly add 250 ml of acetone and 250ml of ethanol, place below -5°C to fully separate out the solid, filter with suction, wash with a small amount of ethanol and chloroform for 3 times, filter with suction, dissolve the obtained solid with a small amount of water, add 200ml of acetone and 100ml of ethanol as a crystallization solvent for recrystallization , placed below -5°C to fully separate the crystals, filter with suction, and vacuum-dry at about 45°C for about 5 hours to obtain 5.2g of off-white crystals, melting point: 140°C ...

Embodiment 2

[0038] Example 2 Preparation of Cefotetan Disodium Monohydrate Add 10 g of cefotetan diacid and 60 ml of water into a reaction flask, stir to form a suspension, add saturated sodium carbonate aqueous solution dropwise at 5°C to bring the pH to 7.0, and stir For 30 minutes, add 0.2 g of activated carbon, stir for 30 minutes, filter with suction, wash with water, and filter with suction, slowly add 300 ml of acetone and 200 ml of acetonitrile dropwise to the filtrate, and place it below -10°C to fully separate out the solid, filter with suction, wash with chloroform three times, and Filter and dissolve the obtained solid with a small amount of water, add 300ml of acetone, 200ml of acetonitrile, and 80ml of diethyl ether as the crystallization solvent for recrystallization, and place it below -10°C overnight to allow the crystals to fully separate out, filter with suction, and dry in vacuum at 45°C for about 5 hours. Obtained 5.6g of off-white crystals, melting point: 141°C discol...

Embodiment 3

[0039] Example 3 Preparation of Cefotetan Disodium 0.5 Hydrate Add 20 g of cefotetan diacid and 130 ml of water into the reaction flask, stir, add saturated sodium bicarbonate solution dropwise to the filtrate at 5°C to bring the pH to 6.9, and stir for 30 Minutes, add 0.2g of activated carbon, stir for 30 minutes, filter with suction, wash with water, filter with suction, slowly add 500ml of acetone and 150ml of diethyl ether dropwise to the filtrate, place it below -5°C to fully separate out the solid, filter with suction, wash with acetone and chloroform for 3 times , suction filtration, the resulting solid was just dissolved with a small amount of water, recrystallized with 300ml of acetone, 300ml of isopropanol, and 20ml of diethyl ether as the crystallization solvent, and placed overnight at -5°C to allow the crystals to fully separate out, suction filtered, and vacuum at 40°C After drying for about 24 hours, 11.2 g of off-white crystals were obtained. Melting point: 142°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com