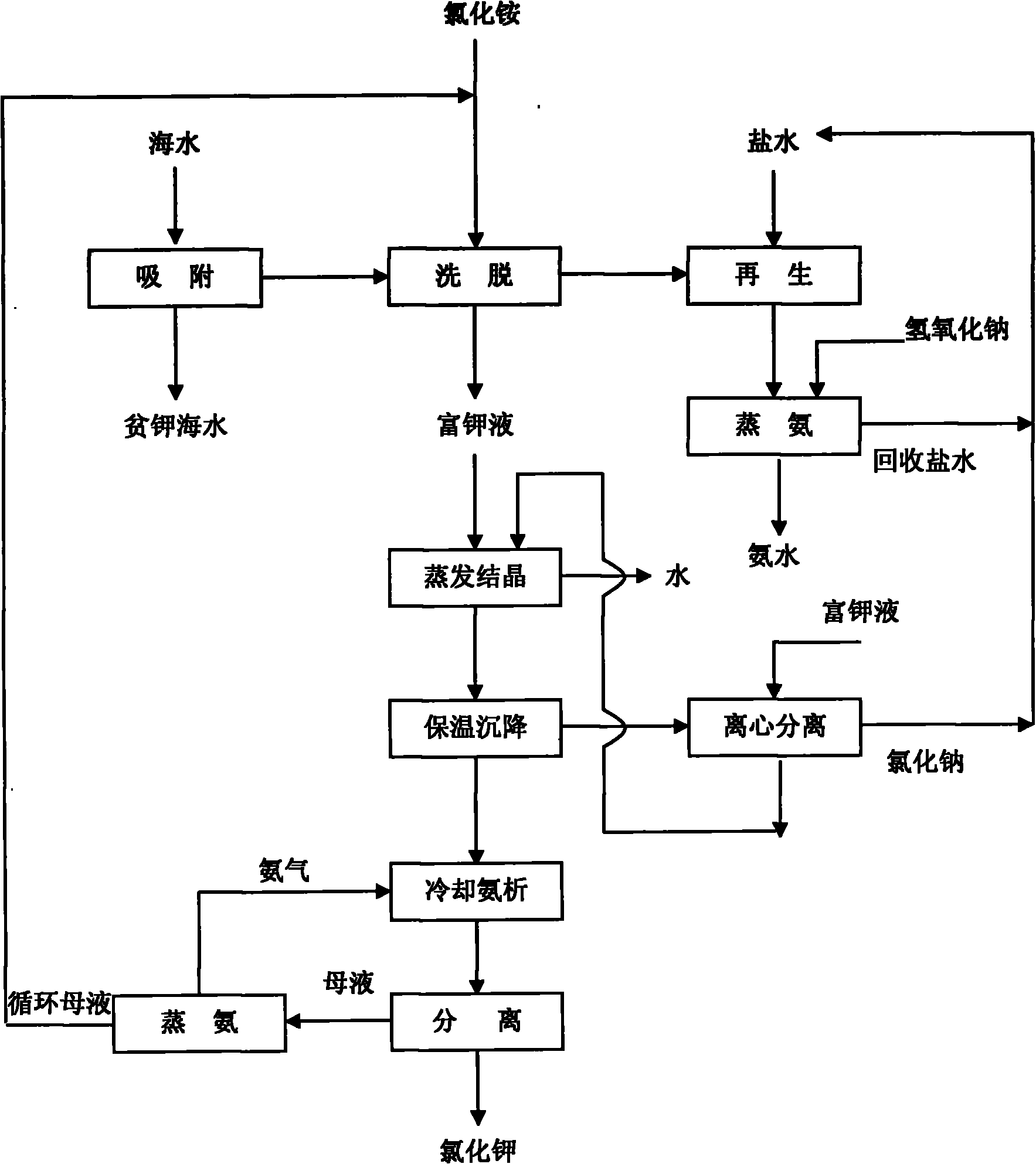

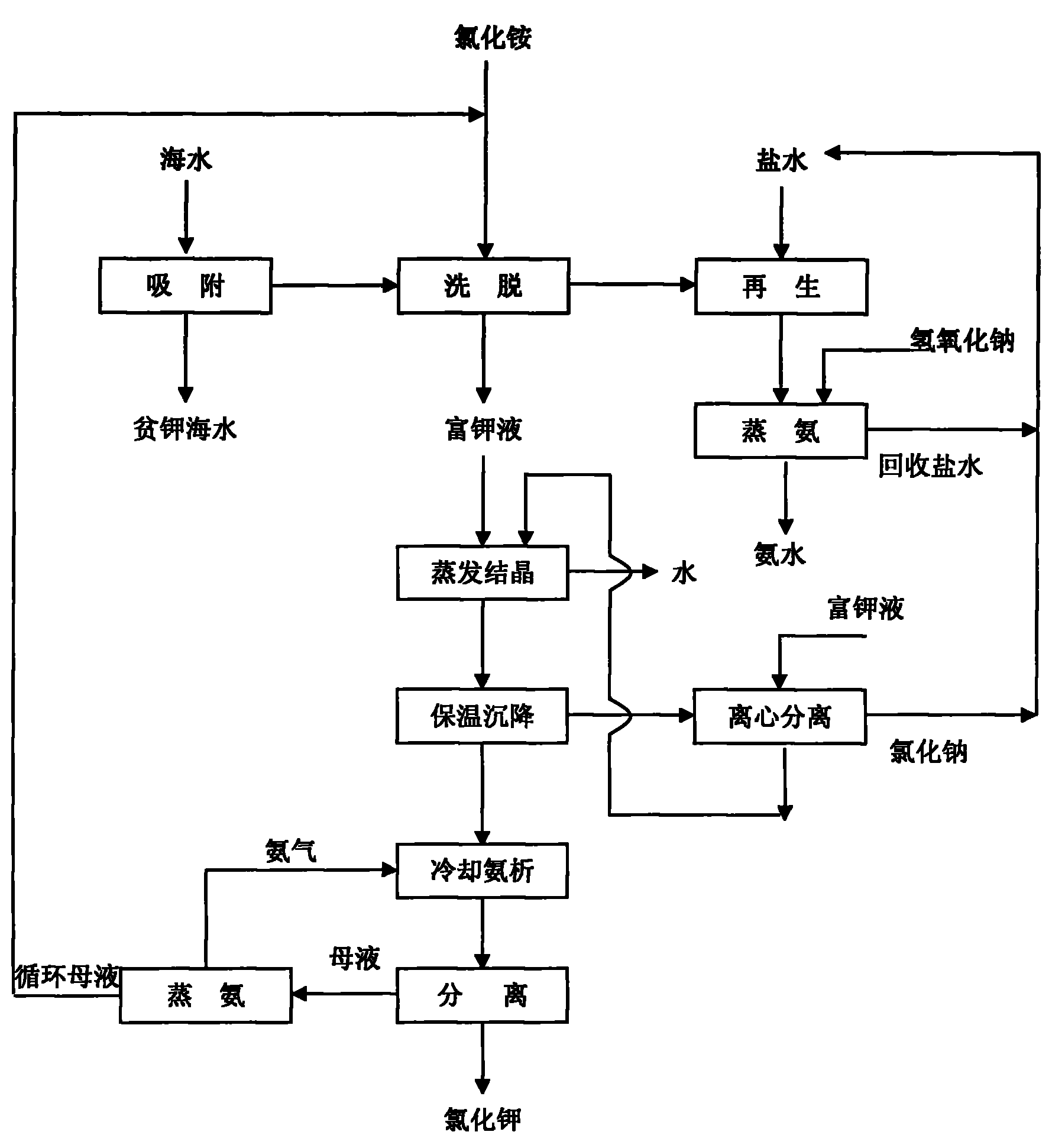

Method for preparing potassium chloride from seawater

A process method and technology of potassium chloride, applied in directions such as alkali metal chloride, can solve the problems of high overall energy consumption, high energy consumption and the like, and achieve the effects of improving economic benefits, simple process and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

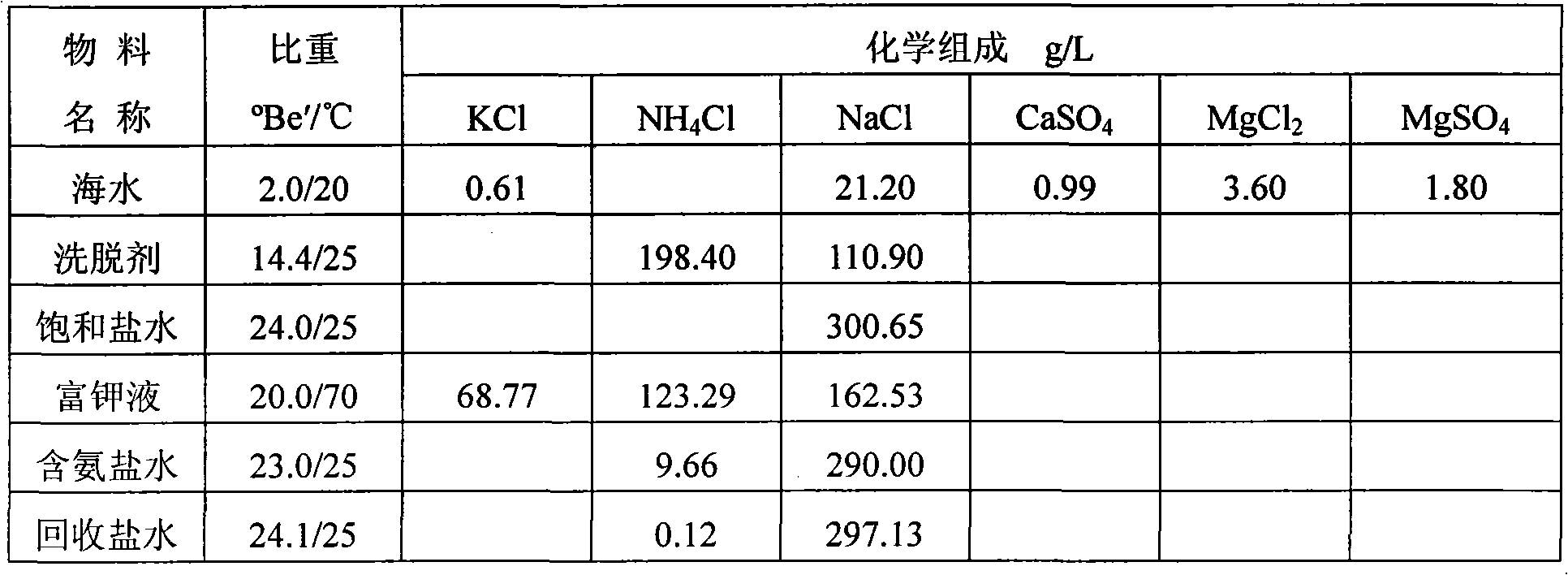

[0021] The first step, preparation of potassium-rich solution

[0022] Firstly, 6000 grams of sodium-type modified zeolite is filled in 6 ion exchange columns with a jacket of φ30×12000 mm, and the ion exchange device is formed in series. Pass into 1000 liters (1014 kilograms) 2 ° of Be ' raw seawater to ion-exchange column with the flow velocity (empty tower flow velocity) of 45 meters / hour then, carry out adsorption, and adsorption temperature is 10 ℃. The potassium concentration in the raw seawater is 0.32 g / L, and the potassium concentration in the seawater discharged after adsorption is 0.22 g / L, and the potassium ions in the seawater are exchanged into the zeolite. Wash all the seawater in the zeolite column with tap water. According to the data in table 1, to above-mentioned ion-exchange column with the flow velocity (superficial tower flow velocity) of 5 meters / hour, pass into the eluent 2700ml (2999 grams) that temperature is 25 ℃ and carry out elution, when obtainin...

Embodiment 2

[0030] The first step, preparation of potassium-rich solution

[0031] Firstly, 6000 grams of sodium-type modified zeolite is filled in 6 ion exchange columns with a jacket of φ30×12000 mm, and the ion exchange device is formed in series. Then feed 150 liters (164 kilograms) of 12 ° Be ' raw material concentrated seawater to the ion exchange column with a flow velocity of 25 m / h for adsorption, and the adsorption temperature is 0 ° C. The potassium concentration in the raw seawater is 1.52 g / L, and the potassium concentration in the discharged seawater after adsorption is 0.70 g / L. Wash all the seawater in the zeolite column with tap water. According to the data in Table 3, the eluent 3000ml (3368 grams) of 95 ℃ of temperature is passed into the above-mentioned ion-exchange column with the flow velocity of 8 meters / hour to carry out elution, stops when obtaining potassium-rich liquid 2700ml (3155 grams) elute. The composition of the potassium-rich liquid is shown in Table 3...

Embodiment 3

[0039] The first step, preparation of potassium-rich solution

[0040] Firstly, 6000 grams of sodium-type modified zeolite is filled in 6 ion exchange columns with a jacket of φ30×12000 mm, and the ion exchange device is formed in series. Then feed 600 liters (631 kilograms) of 7 ° Be ' raw material concentrated seawater to the ion exchange column with a flow velocity of 35 m / h for adsorption, and the adsorption temperature is 30 ° C. The potassium concentration in the raw seawater is 0.71 g / L, and the potassium concentration in the discharged seawater after adsorption is 0.55 g / L. Potassium ions in seawater are exchanged into zeolites. Wash all the seawater in the zeolite column with tap water. According to the data in Table 5, 2300ml (2586 grams) of eluent 2300ml (2586 grams) of 85 ℃ of temperature is passed into the above-mentioned ion-exchange column with the flow velocity of 10 meters / hour to carry out elution, stop when obtaining potassium-rich liquid 2100ml (2482 gram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com