Composite film with photocatalytic oxidability and preparation method thereof

A photocatalytic oxidation and composite thin film technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of small specific surface area and poor catalytic effect of catalytic pollutants Ideal, catalyst separation and recovery difficulties, etc., to achieve the effect of being beneficial to the photocatalytic reaction, good photocatalytic activity, and beneficial to the photocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (manufacturing process)

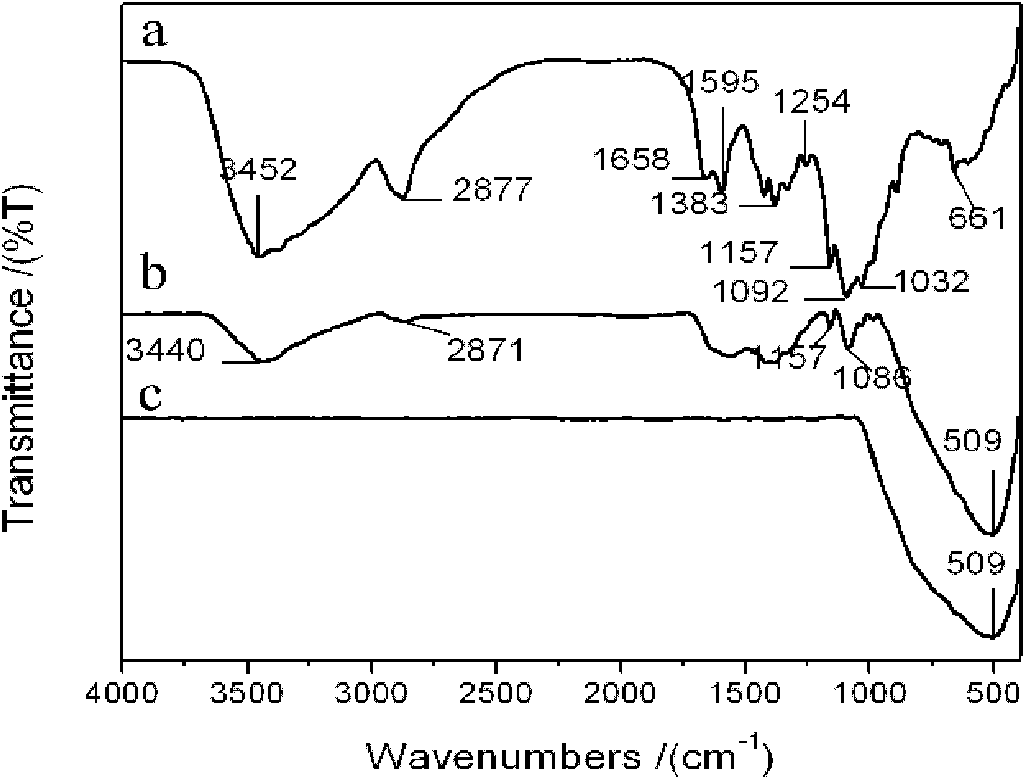

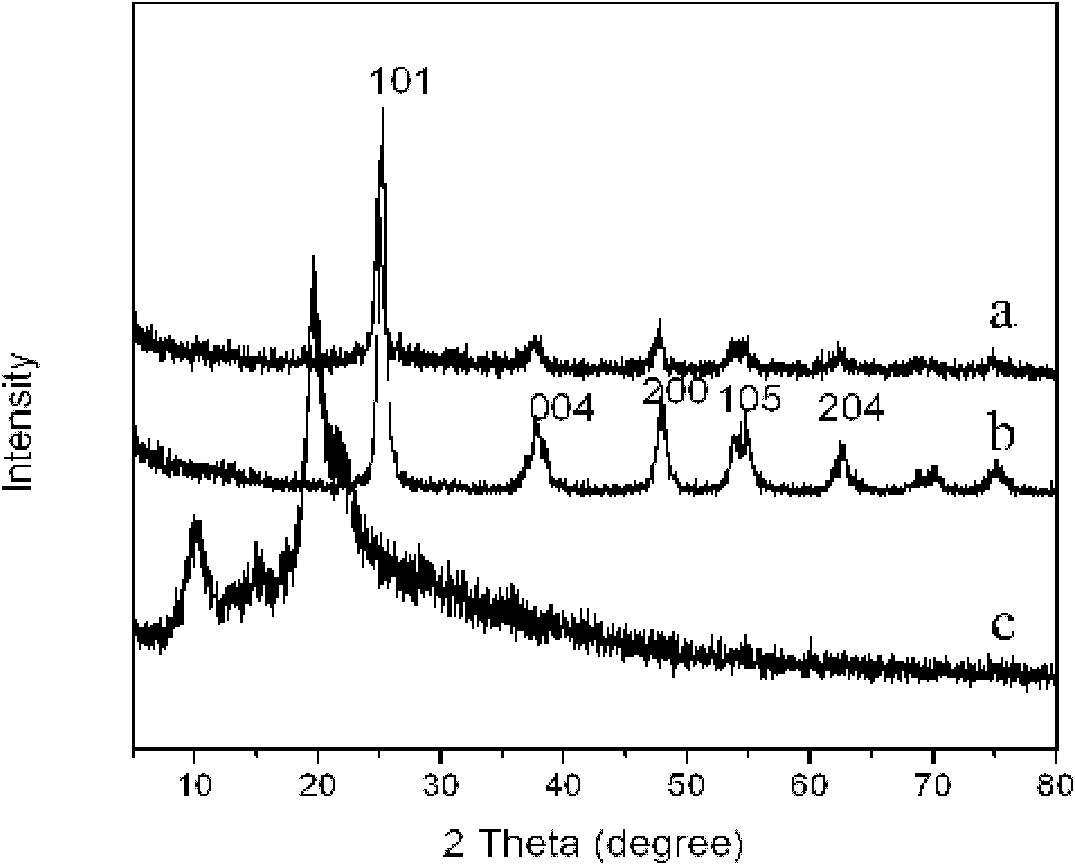

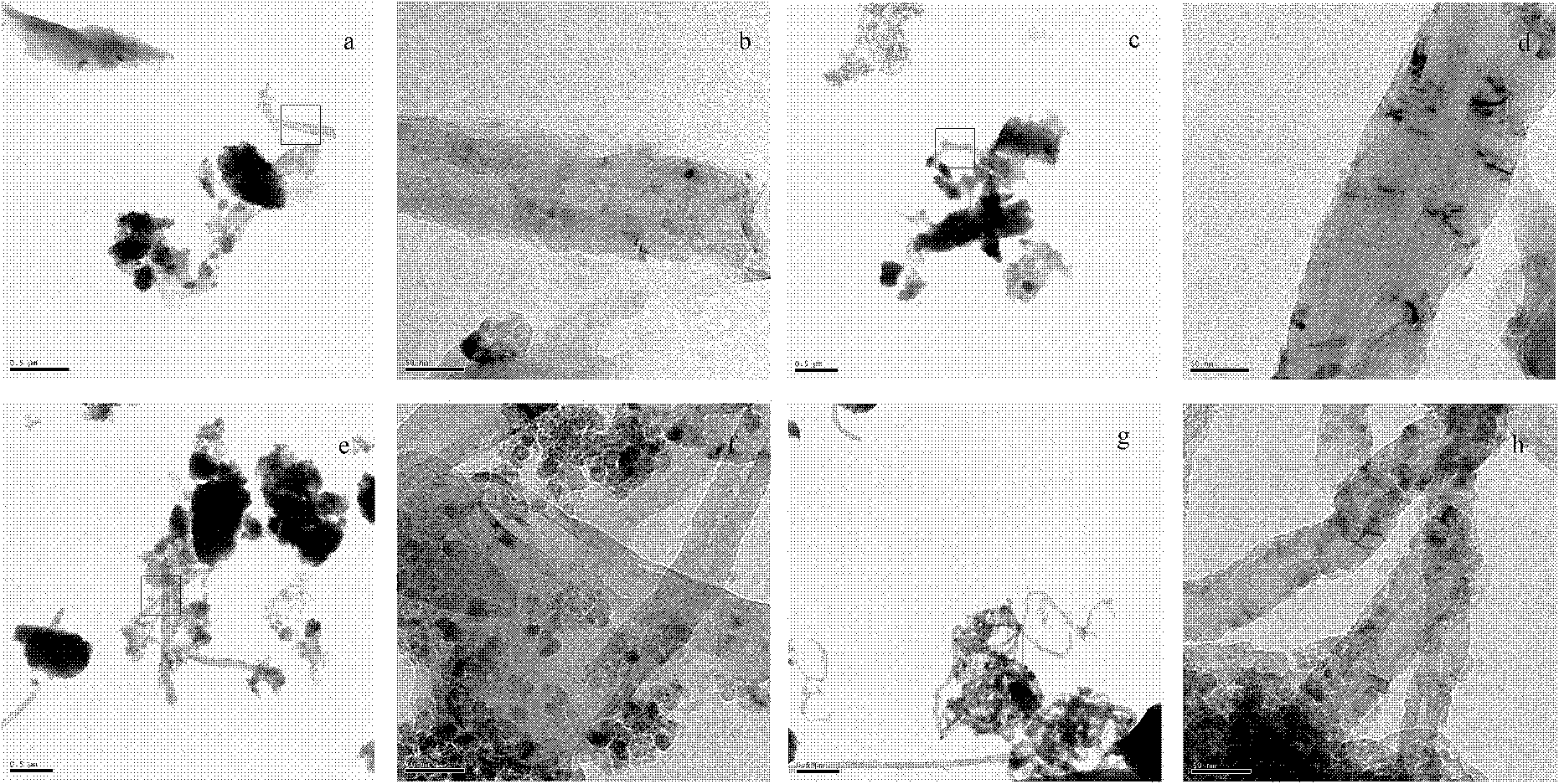

[0028] Take 5ml of tetrabutyl titanate and 10ml of absolute ethanol in a 20ml beaker, and stir for 30min to obtain a colorless and transparent solution; take another 0.112g of carbon nanotubes (40-60nm) and ultrasonically disperse them in a 10ml beaker In absolute ethanol, ultrasonically disperse for 15 minutes to obtain a uniformly dispersed suspension, then add the absolute ethanol dispersion of carbon nanotubes to the solution of tetrabutyl titanate drop by drop and stir at a rate of 0.5 drops / second After the dropwise addition, continue to vigorously stir for 30 minutes to obtain a uniform mixed solution. Then use a syringe to add 1.5ml of acetic acid solution (the molar ratio of acetic acid to water is 0.055:1) dropwise into the mixed solution and stir at a rate of 0.2 drops / second. After the dropwise addition, continue to stir for 30 minutes to obtain titanium dioxide / carbon The nanotube sol was then dried at room temperatur...

Embodiment 2

[0030] Embodiment 2 (manufacturing process)

[0031] Take 5ml of tetrabutyl titanate and 10ml of absolute ethanol in a 20ml beaker, and stir for 30min to obtain a colorless and transparent solution; another 0.056g of carbon nanotubes (40-60nm) are ultrasonically dispersed in a 10ml beaker In absolute ethanol, ultrasonically disperse for 15 minutes to obtain a uniformly dispersed suspension, then add the absolute ethanol dispersion of carbon nanotubes to the solution of tetrabutyl titanate drop by drop and stir at a rate of 0.5 drops / second After the dropwise addition, continue to vigorously stir for 30 minutes to obtain a uniform mixed solution. Then use a syringe to add 1.5ml of acetic acid solution (the molar ratio of acetic acid to water is 0.055:1) dropwise into the mixed solution and stir at a rate of 0.2 drops / second. After the dropwise addition, continue to stir for 30 minutes to obtain titanium dioxide / carbon The nanotube sol was then dried at room temperature and age...

Embodiment 3

[0033] Embodiment 3 (manufacturing process)

[0034] Take 5ml of tetrabutyl titanate and 10ml of absolute ethanol in a 20ml beaker, and stir for 30min to obtain a colorless and transparent solution; another 0.0224g of carbon nanotubes (40-60nm) are ultrasonically dispersed in a 10ml beaker In absolute ethanol, ultrasonically disperse for 15 minutes to obtain a uniformly dispersed suspension, then add the absolute ethanol dispersion of carbon nanotubes to the solution of tetrabutyl titanate drop by drop and stir at a rate of 0.5 drops / second After the dropwise addition, continue to vigorously stir for 30 minutes to obtain a uniform mixed solution. Then use a syringe to add 1.5ml of acetic acid solution (the molar ratio of acetic acid to water is 0.055:1) dropwise into the mixed solution and stir at a rate of 0.2 drops / second. After the dropwise addition, continue to stir for 30 minutes to obtain titanium dioxide / carbon The nanotube sol was then dried at room temperature and ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com