Iron-carbon nano composite electromagnetic wave absorption material and preparation method thereof

A technology of carbon nanocomposite and absorbing materials, which is applied in the field of preparation of iron-carbon nanocomposite electromagnetic wave absorbing materials, to achieve the effect of improving electromagnetic wave absorbing performance, excellent electromagnetic wave absorbing performance and good wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

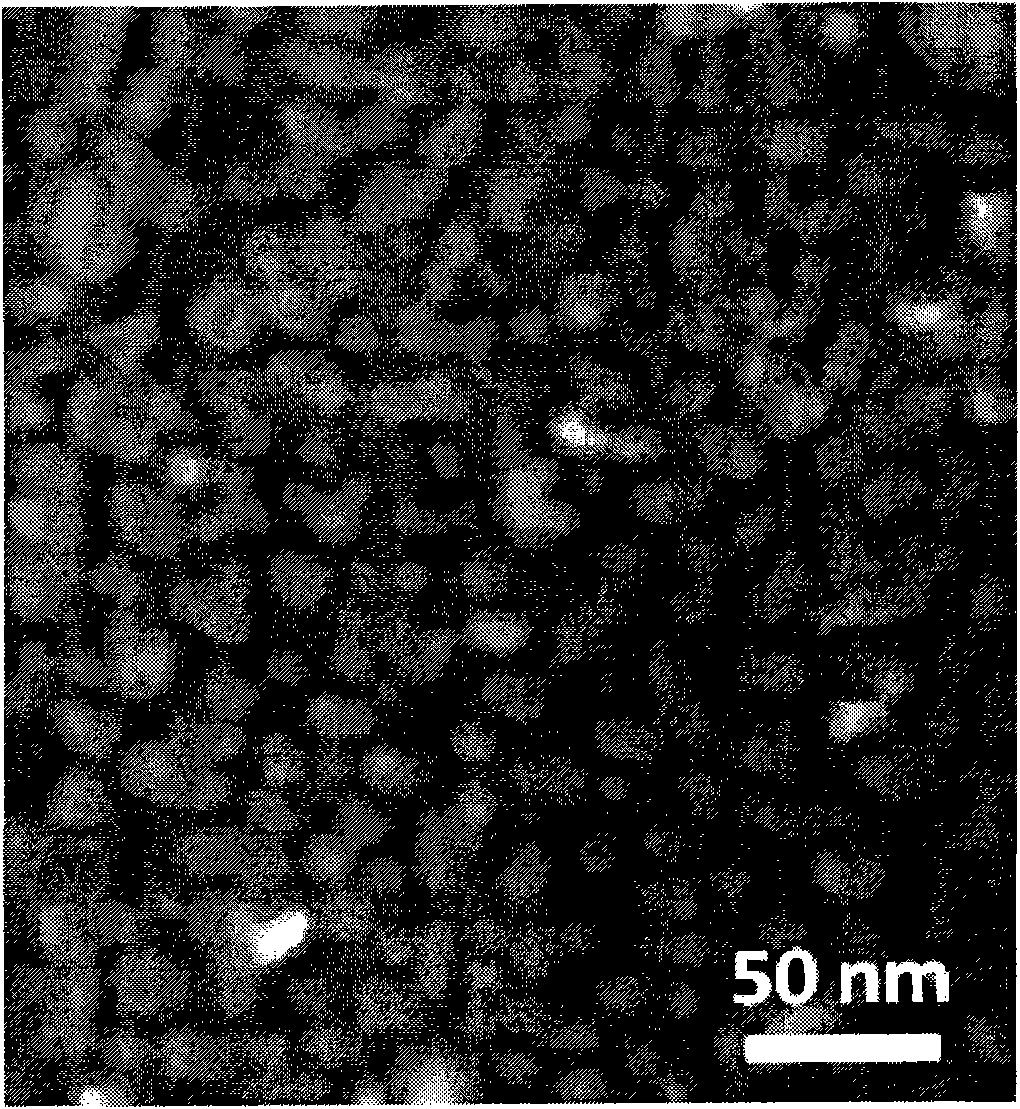

Embodiment 1

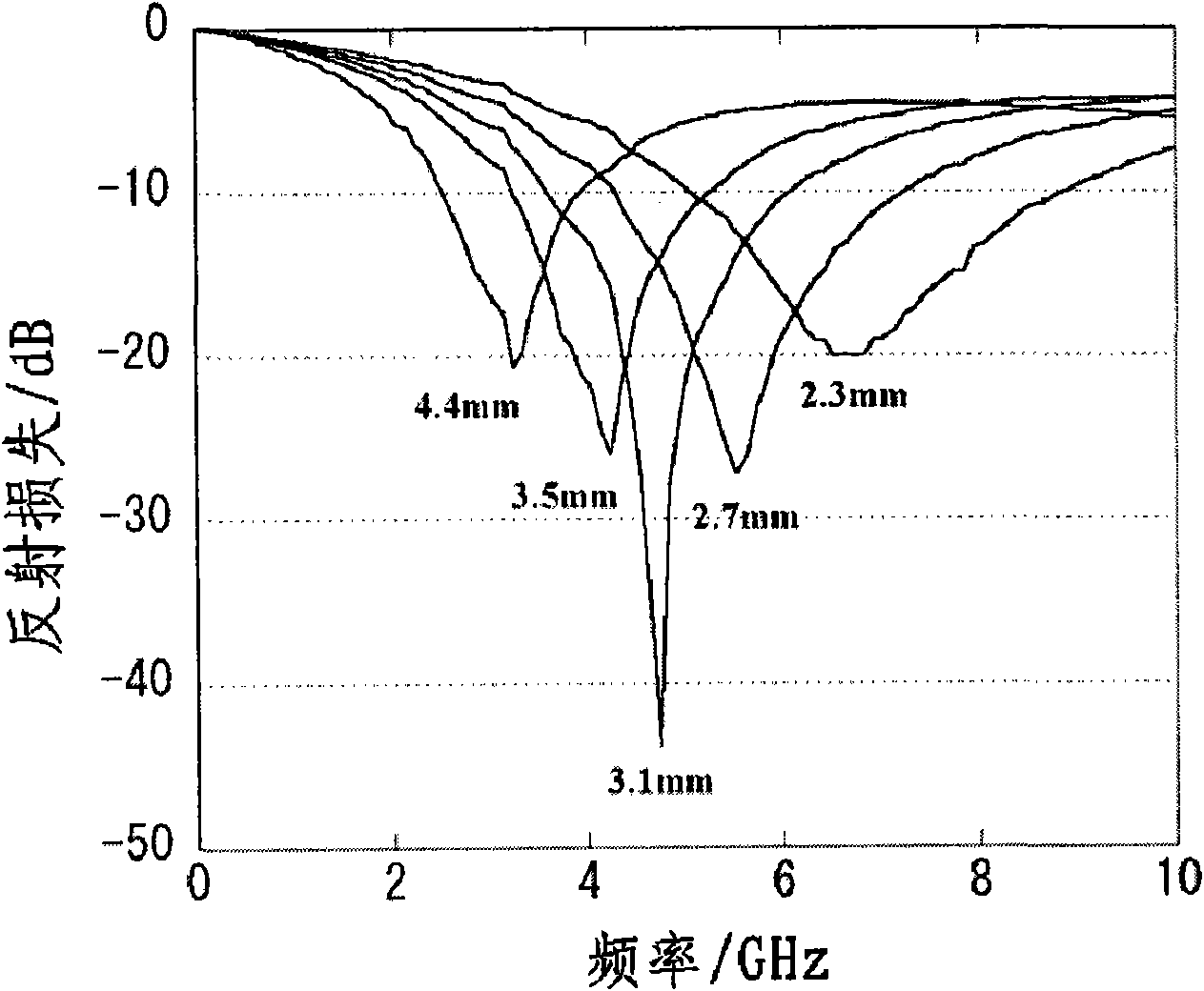

[0033] Iron carbonyl was used as the precursor of iron, methane was used as the precursor of C, and argon was used as the carrier gas of iron carbonyl. The carrier gas carries iron carbonyl into the gas reactor through a gas pipeline, and methane enters the gas reactor through another gas pipeline. The flow rate of the carrier gas is 150 SCCM, and the flow rate of the methane gas is 20 SCCM. Under the reaction conditions of 300-500°C, the mixed gas was thermally decomposed to prepare iron-carbon nanocomposites, and the contents of C and iron were measured by EDX energy spectrum to be 7% and 93%, respectively.

[0034] The obtained iron-carbon nanocomposite powder was mixed with epoxy resin at a mass ratio of 1:4 and pressed into a ring-shaped sample (D 外 × d 内 ×h=7×3.04×1.5mm), related parameter μ r and ε r Measured with an Agilent Technologies E8363A electromagnetic wave vector network analyzer, the reflection loss is measured by μ r , ε r , the absorption frequency and...

Embodiment 2

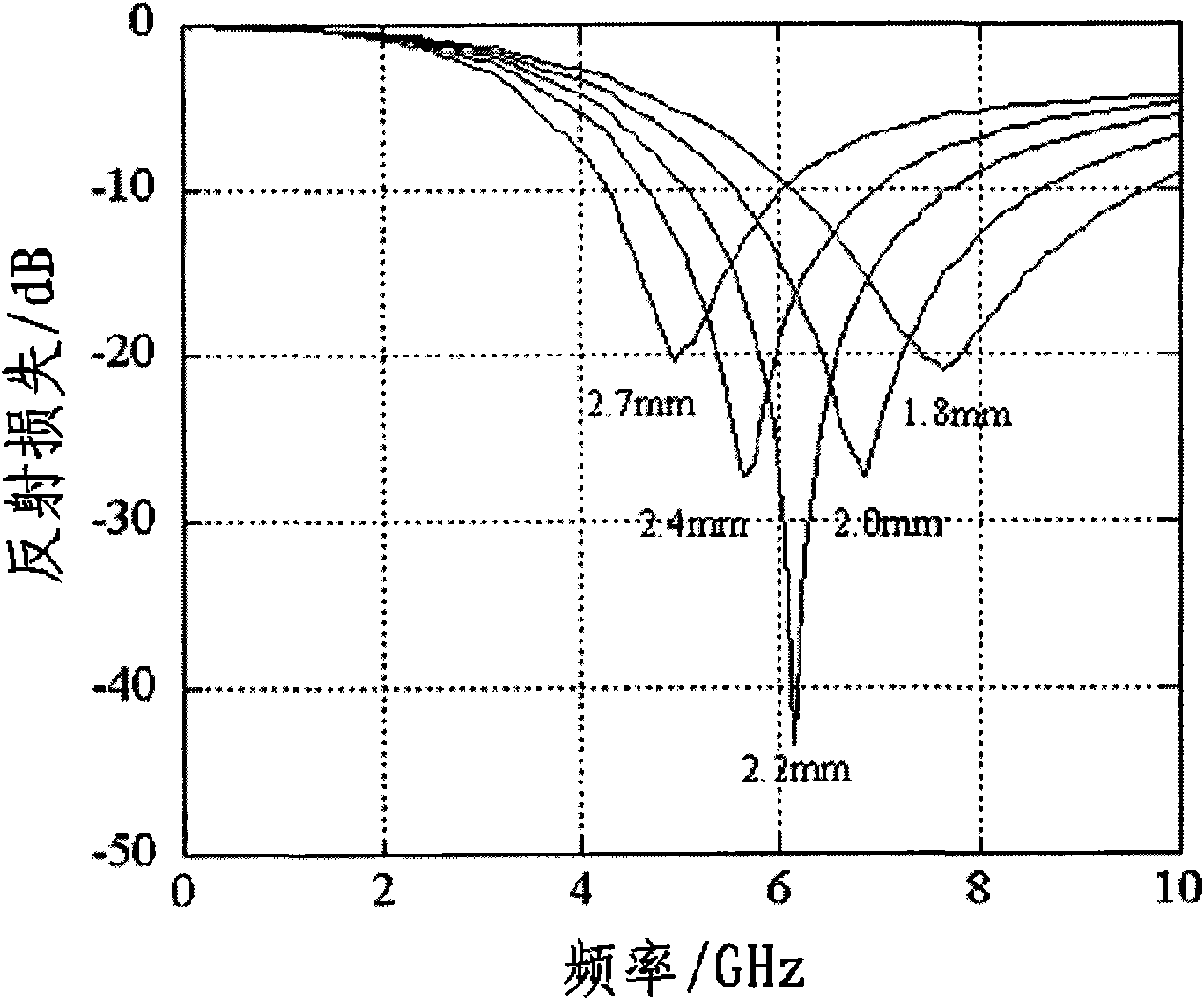

[0036] Iron carbonyl was used as the precursor of iron, acetylene was used as the precursor of C, nitrogen was used as the carrier gas of iron carbonyl, and the flow rate of the carrier gas was 150 SCCM. The flow rate of acetylene gas is 20SCCM. Under the reaction conditions of 300-500°C, the mixed gas is thermally decomposed to prepare iron-carbon nanocomposites. The contents of C and iron measured by EDX energy spectrum are 5% and 95% respectively.

[0037] The obtained iron-carbon nanocomposite powder was mixed with epoxy resin at a mass ratio of 1:4 and pressed into a ring-shaped sample (D 外 × d 内 ×h=7×3.04×1.5mm), related parameter μ r and ε r Measured with an Agilent Technologies E8363A electromagnetic wave vector network analyzer, the reflection loss is measured by μ r , ε r, the absorption frequency and the thickness of the sample. Measured ε r ’ and ε r ” almost keeps a constant in the range of 0.05-20.05GHz with values of 17 and 0.9 respectively, μ r ’ has ...

Embodiment 3

[0039] As described in Example 1, the difference is that under the reaction conditions of 500-700 ° C, the mixed gas is prepared by thermal decomposition to obtain iron-carbon nanocomposites, and the contents of C and iron measured by EDX energy spectrum are 8% respectively and 92%.

[0040] The obtained iron-carbon nanocomposite powder was mixed with epoxy resin at a mass ratio of 1:4 and pressed into a ring-shaped sample (D 外 × d 内 ×h=7×3.04×1.5mm), related parameter μ r and ε r Measured with an Agilent Technologies E8363A electromagnetic wave vector network analyzer, the reflection loss is measured by μ r , ε r , the absorption frequency and the thickness of the sample. Measured ε r ’ and ε r ” almost keeps a constant in the range of 0.05-20.05GHz with values of 13 and 0.7 respectively, μ r ’ has a maximum value of 3.7, μ r The maximum value of "is 0.94, the minimum value of its absorption peak is -37dB (decibels), the bandwidth of the absorption rate is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com