Method for preparing general nano metal sulphide

A nano metal and sulfide technology, applied in the field of material chemistry, can solve the problems of low phase purity, difficult control of size and valence, and harsh preparation conditions, and achieve easy control of reaction conditions, high yield and good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

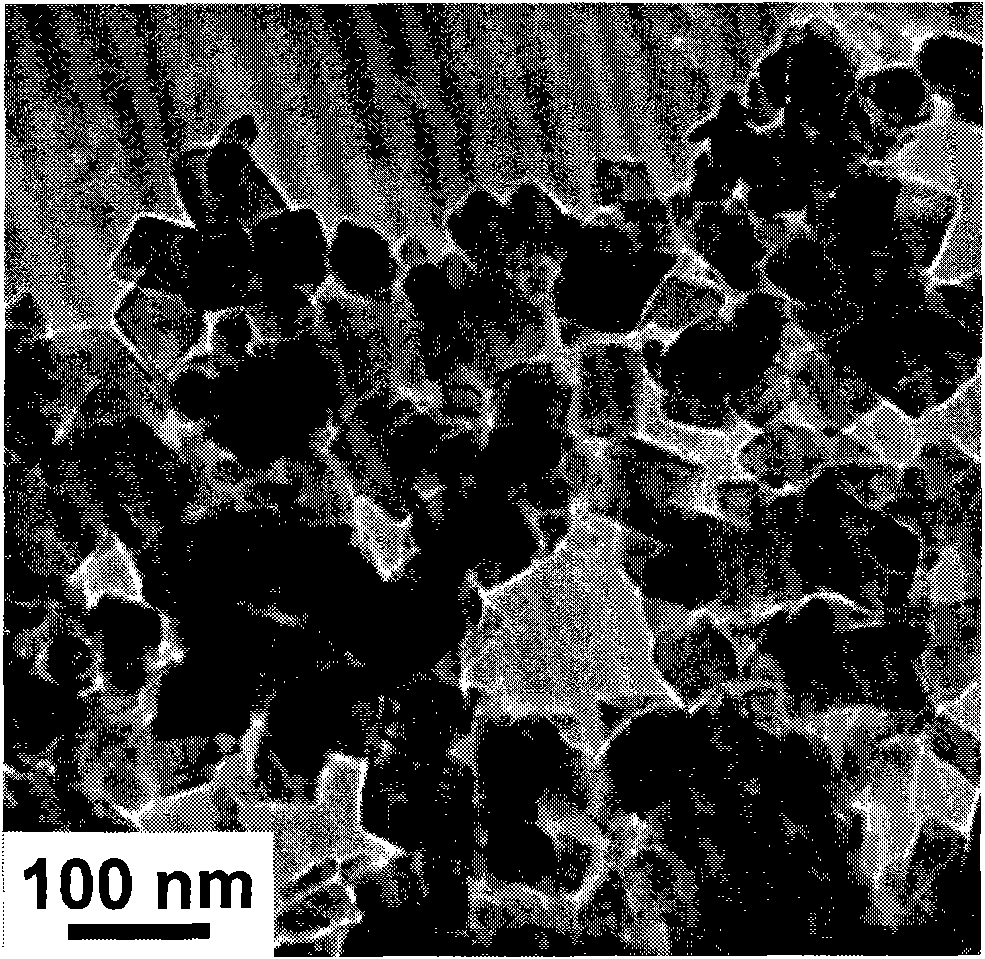

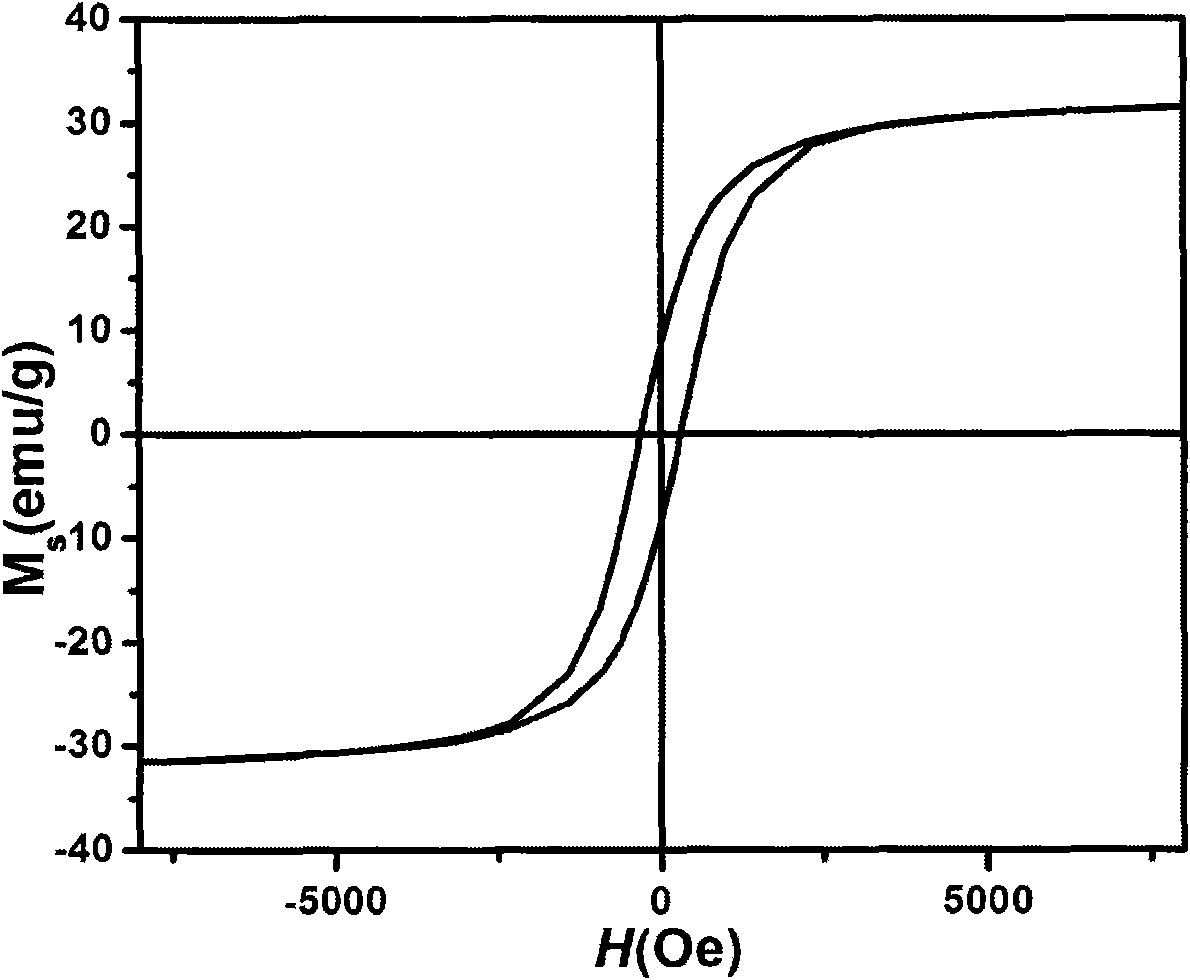

[0033] With 0.2mmol of iron diethyldithiocarbamate (Fe(DDTC) 3 ) as a raw material, dissolved in a three-necked flask equipped with a mixed solvent of oleic acid, oleylamine and octadecene (10mmol: 10mmol: 20mmol), pumped and heated to about 120°C, kept for 20min, and then heated up under the protection of an inert gas Keep it at 280°C for 1 hour. Finally, after the solution is naturally cooled to room temperature, add 50mL of absolute ethanol, centrifuge, wash and dry, and the obtained black powder is identified as cubic phase Fe by X-ray diffraction using a transmission electron microscope. 3 S 4 nanoparticles (such as figure 1 shown); the obtained nanoparticles are as figure 2 Fe 3 S 4 It has very good magnetic properties as shown in the saturation magnetization curve.

Embodiment 2

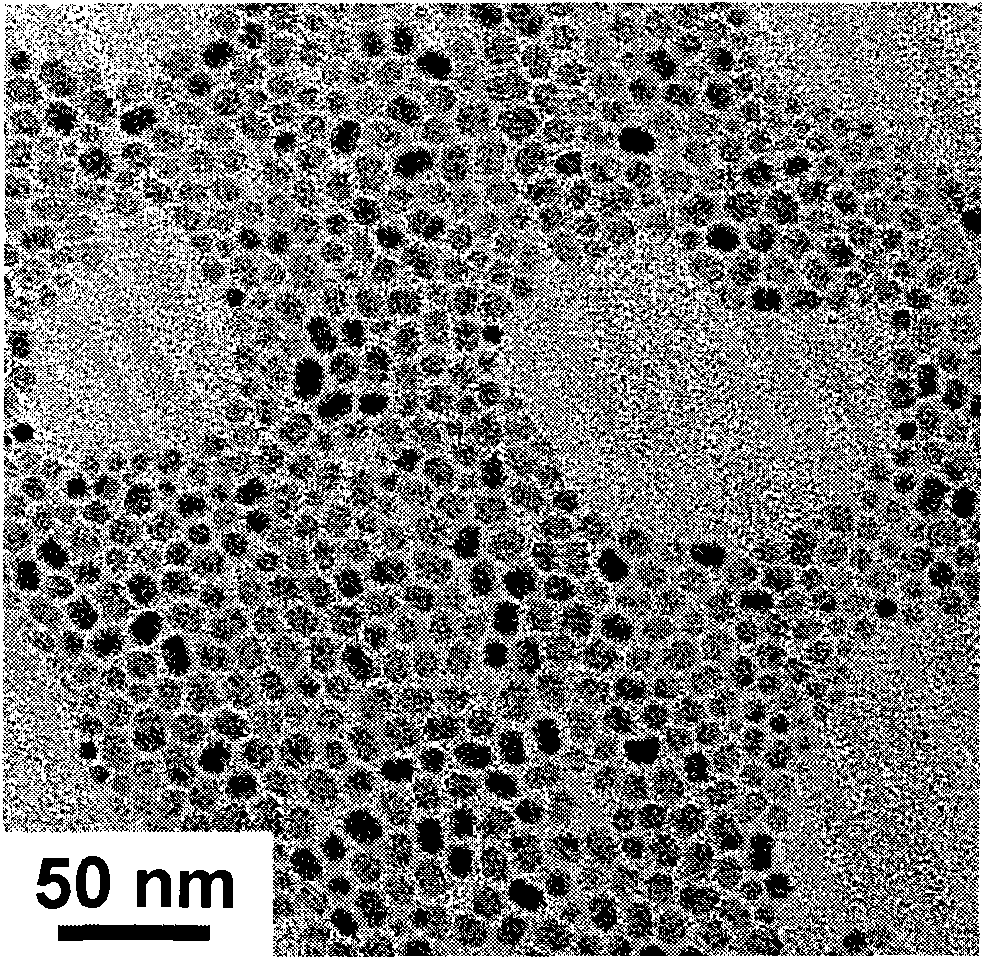

[0035] With 0.2mmol of zinc diethyldithiocarbamate (Zn(DDTC) 2) as a raw material, dissolved in a three-necked flask equipped with a mixed solvent of oleic acid and oleylamine (40mmol: 40mmol), pumped and heated to about 100°C, kept for 30min, and then heated to 300°C for 1 hour under the protection of an inert gas , after the solution is naturally cooled to room temperature, add 50mL absolute ethanol, centrifuge, wash and dry, the white powder of gained is identified as the ZnS nanoparticle of hexagonal phase through X-ray diffraction (such as image 3 shown). The resulting nanoparticles have excellent optical properties (e.g. Figure 4 shown).

[0036] In summary, the present invention utilizes the method of thermal decomposition of high-boiling point mixed solvents, through the control of the thermal decomposition process of the precursor and the solvent composition, to realize the control of the crystal nucleation and growth process, and further obtain high yield, unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com