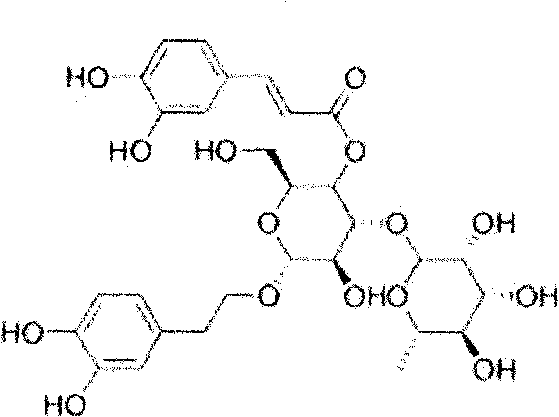

Process for preparing verbascoside

A technology of verbascoside and process, which is applied in the field of preparing verbascoside, can solve the problems of inconvenient continuous operation, low yield, poor product quality, etc., and achieve the effects of short production cycle, high extraction rate and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 20kg of large plantain seed (8.6mg / g), put it into an extraction tank, add 300L saturated lime water and soak at 60°C for 1.5 hours, then ultrasonically extract for 1 hour, filter, extract twice, adjust the pH to 7 with hydrochloric acid solution, and obtain Add 2.9kg of activated carbon to 580L extract, stir for half an hour, filter, then add 2 times the amount of petroleum ether to degrease. The degreased liquid is first processed through the microfiltration membrane system, and then passed through the ultrafiltration membrane system to collect the permeate, add the permeate to D101 macroporous resin for adsorption, first use 6 times the column volume of deionized water to elute impurities, and then use 5 times the column volume of n-butanol for elution, collect the eluent, recover the solvent, concentrate it into an extract, mix the extract with an equal amount of polyamide and put the sample on the column, first use 2 times the column volume of ethyl acetate / met...

Embodiment 2

[0033] Pulverize Budisma japonica (2%), put 10kg into the extraction tank, add 120L of 2% sodium carbonate solution and soak at 40°C for 2 hours, then ultrasonically extract for 1 hour, filter, extract twice, adjust the pH to 8 with hydrochloric acid solution, and obtain 200L of extract, add 1.5kg of activated carbon and stir for 1 hour, filter, then add double amount of 1 petroleum ether to degrease. The degreased liquid is first processed through the microfiltration membrane system, and then passed through the ultrafiltration membrane system to collect the permeate, add the permeate to HPD100 macroporous resin for adsorption, first use 5 times the column volume of deionized water to elute and remove impurities, and then use 6 times the column volume of n-butanol for elution, collect the eluent, recycle the solvent, concentrate it into an extract, mix the extract with an equal amount of polyamide and put the sample on the column, first use 3 times the column volume ethyl aceta...

Embodiment 3

[0035] Grind Artemisia annua (1.4%), put 10kg into the extraction tank, add 180L saturated lime water to soak for 3 hours at 50°C, then ultrasonically extract for 0.5 hour, filter, extract twice, adjust the pH to 7 with hydrochloric acid solution, and obtain 340L Add 3.4kg of active carbon to the extract, stir for 0.5 hour, filter, then add 3 times the amount of petroleum ether to degrease. The degreased liquid is first processed through the microfiltration membrane system, and then passed through the ultrafiltration membrane system to collect the permeate, add the permeate to AB-8 macroporous resin for adsorption, and first use 4 times the column volume of deionized water to elute and remove impurities. Use 7 times the column volume of n-butanol to elute, collect the eluate, recover the solvent, concentrate it into an extract, mix the extract with an equal amount of polyamide and put it on the column, first use 2 times the column volume ethyl acetate / methanol ( 9:1) and 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com