Preparation method of nanometer fiber immobilization beta-D-galactosidase

A technology of galactosidase and nanofibers, which is applied in the fields of immobilization on/in organic carriers, fiber treatment, textiles and papermaking, etc., to achieve the effect of mild immobilization conditions and high vitality maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Accurately weigh 3.5 g of PSMA and dissolve it in 10 mL of N,N-dimethylformamide, and stir it with magnetic stirring at room temperature to make it fully dissolved to obtain an electrospinning solution with a concentration of 35% (W / V). 5 mL of electrospinning solution was sucked into a syringe equipped with an 8-gauge needle for electrospinning, the distance from the syringe needle to the receiving plate was 25 cm, the flow rate of the electrospinning solution was 250 μL / h, the voltage was 21 kV, and PSMA nanofibers were obtained after electrospinning for 30 min. Leave at room temperature until the solvent evaporates completely.

[0016] 1 mg of PSMA nanofibers were soaked in 1 mL of 25% (V / V) ethanol aqueous solution for 15 min, and washed twice with deionized water and 0.2 mol / L acetic acid-sodium acetate buffer solution (pH 4.0) respectively. A β-gal solution with a concentration of 1.0 mg / mL was prepared with acetic acid-sodium acetate buffer solution (0.2 mol / L) a...

Embodiment 2

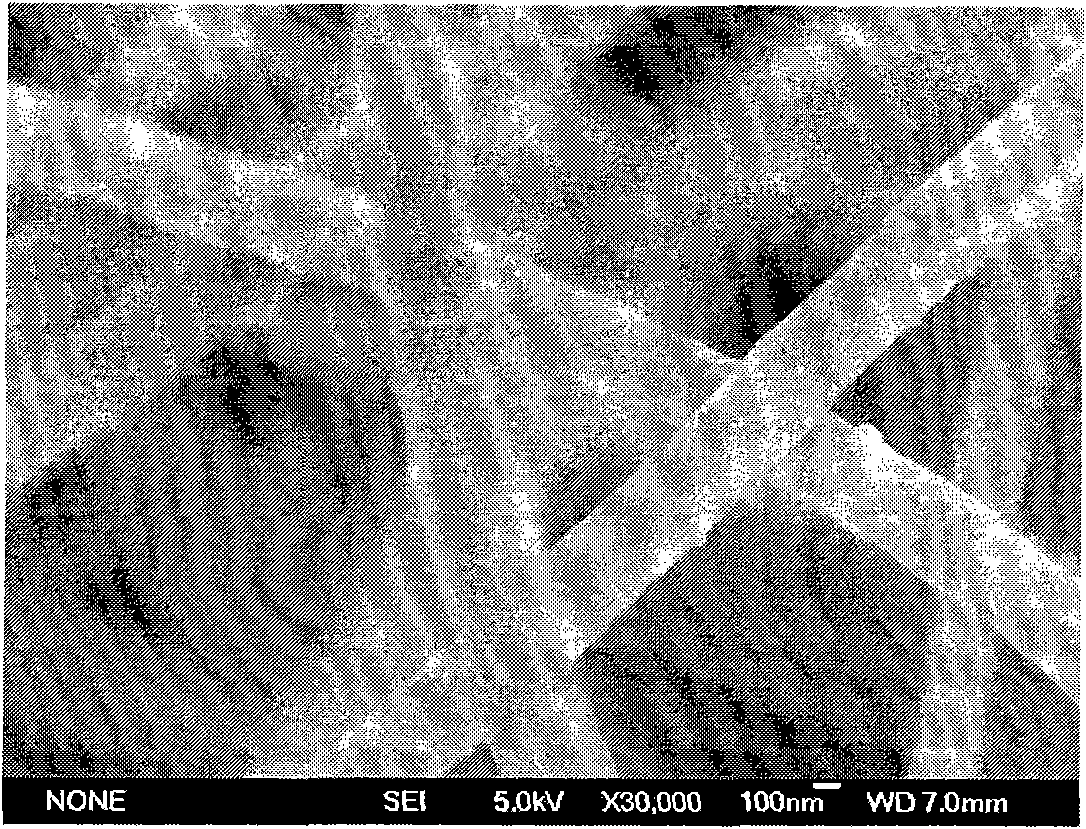

[0018] Accurately weigh 3.5 g of PSMA and dissolve it in 10 mL of N,N-dimethylacetamide, and stir it with magnetic stirring at room temperature to make it fully dissolved to prepare an electrospinning solution with a concentration of 35% (W / V). 5 mL of electrospinning solution was sucked into a syringe equipped with an 8-gauge needle for electrospinning, the distance from the syringe needle to the receiving plate was 25 cm, the flow rate of the electrospinning solution was 250 μL / h, the voltage was 21 kV, and PSMA nanofibers were obtained after electrospinning for 30 min. After the solvent was completely evaporated at room temperature, the microscopic morphology of the nanofibers was characterized by a scanning electron microscope (SEM). The SEM pictures showed that the diameter of the fibers was about 300 nm.

[0019] 1 mg of PSMA nanofibers were soaked in 1 mL of 25% (V / V) ethanol aqueous solution for 15 min, and washed twice with deionized water and 0.2 mol / L acetic acid-sod...

Embodiment 3

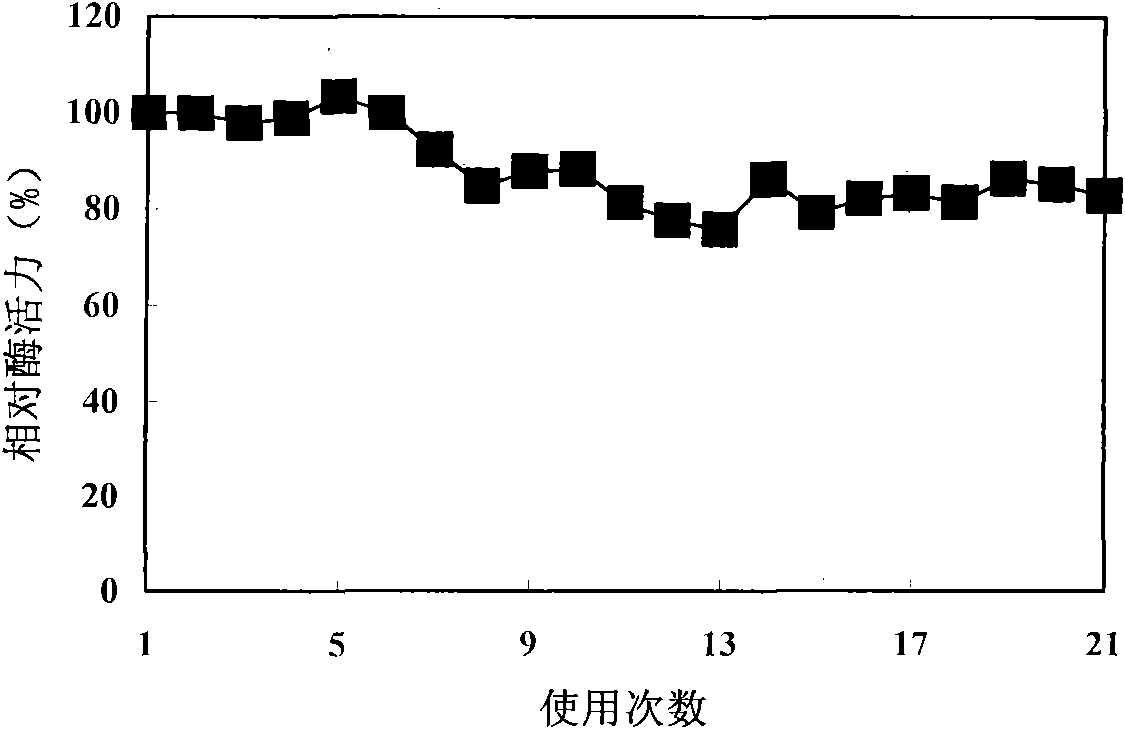

[0021] The immobilized β-gal prepared in Example 2 was used to catalyze the hydrolysis of 2-nitrophenol β-D-galactopyranoside (ONPG), and 1 mg of immobilized β-gal was added to 5 mL of ONPG preheated to 37 °C In the solution (0.2mol / L acetic acid-sodium acetate buffer solution, pH4.5), place the reaction solution in a 70rpm shaker for 20min, take out 100μL of the reaction solution and add 1mol / LNa 2 CO 3 100 μL to stop the reaction. The absorbance value of the solution was measured at 405 nm to calculate the enzymatic activity. After the reaction was completed, the immobilized enzyme was washed with 5 mL of 0.2 mol / L acetic acid-sodium acetate buffer solution (pH 4.5), and then put into the next reaction. The immobilized β-gal could still maintain 85% catalytic activity after repeated use for 21 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com