Preparation and application of natural polymer binder capable of realizing photopolymerization

A natural polymer and adhesive technology, applied in the direction of dextran adhesives, adhesive types, chitin adhesives, etc., can solve the problems of adhesives that cannot be fast and degraded, and achieve easy operation , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

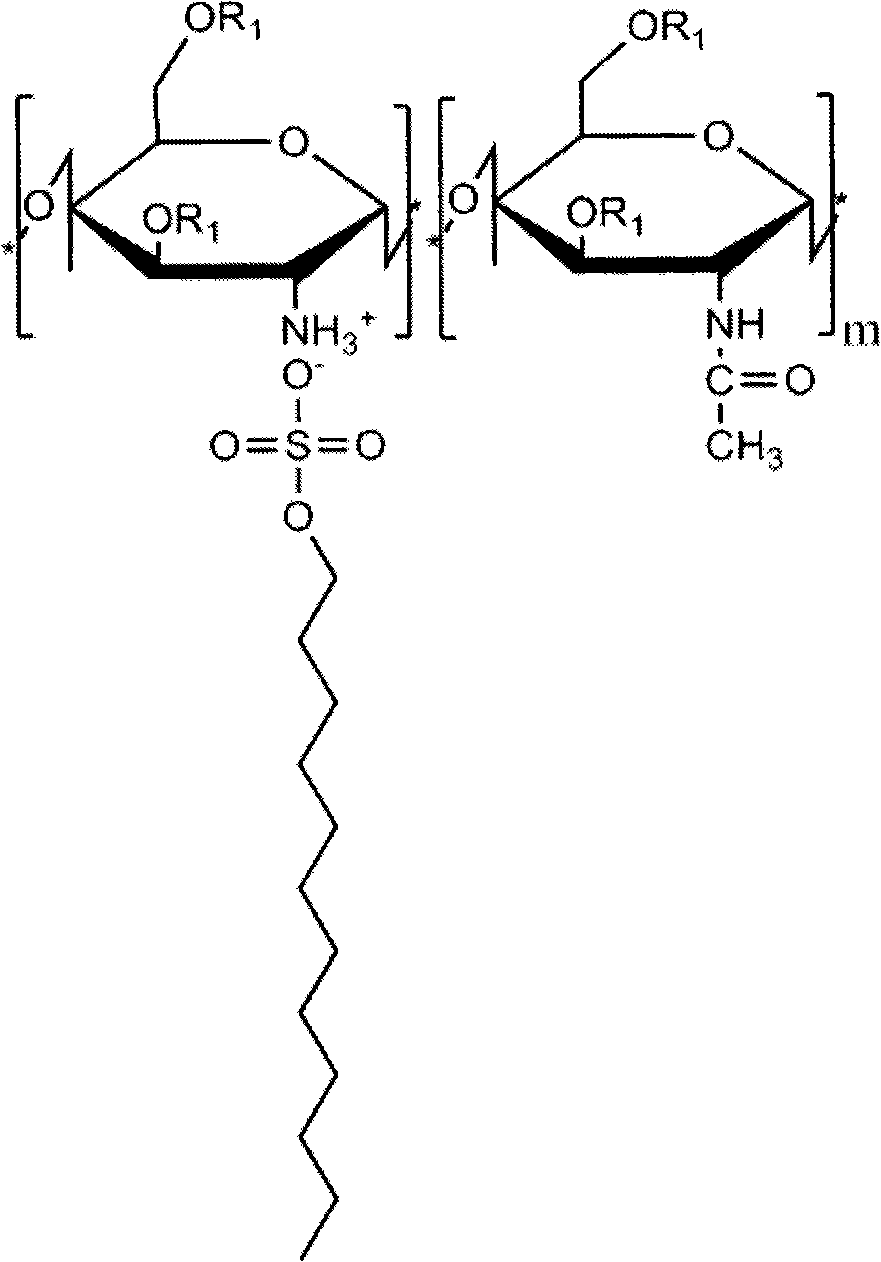

[0028] Dissolve 8g of chitosan in 500mL of 2% acetic acid aqueous solution, then dissolve 28.8g of sodium dodecylsulfonate in 500mL of water, mix the two solutions, stir vigorously for 2 hours and then filter with suction. The product was washed three times with suction and then freeze-dried. Take 8 g of the freeze-dried product and dissolve it in 250 mL of dimethyl sulfoxide, put it into the reaction vessel after being completely dissolved, and then add 5 drops of the catalyst dibutyltin dilaurate. Add 8 g of ethyl methacrylate isocyanate into 100 mL of dimethyl sulfoxide, drop it into the reaction vessel through a constant pressure dropping funnel under nitrogen atmosphere, stir vigorously, and heat in a water bath at 35°C. Use FTIR to monitor the reaction progress in real time, when 2267cm -1 If the peak does not disappear within 20 minutes, the reaction ends and the dropwise addition is stopped. The reaction product was added into deionized water, and the precipitate was...

Embodiment 2

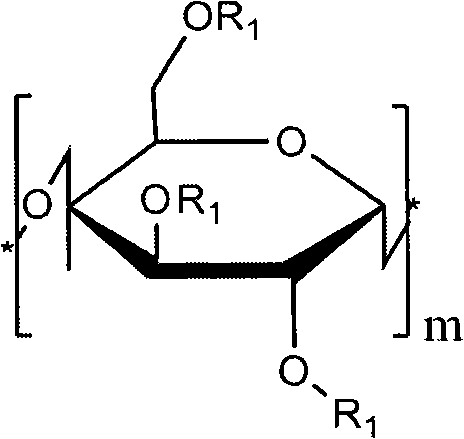

[0031] Dissolve 8 g of starch with 250 ml of dimethyl sulfoxide, put it into the reaction vessel after it is completely dissolved, and then add 8 drops of the catalyst dibutyltin dilaurate. Add 12 g of ethyl methacrylate isocyanate into 100 mL of dimethyl sulfoxide, drop it into the reaction vessel through a constant pressure dropping funnel under nitrogen atmosphere, stir vigorously, and heat in a water bath at 35°C. Use FTIR to monitor the reaction progress in real time, when 2267cm -1 If the peak does not disappear within 20 minutes, the reaction ends and the dropwise addition is stopped. The reaction product was added into deionized water, and the precipitate was filtered and washed several times to obtain the final product.

[0032] The product is diluted with dimethyl sulfoxide to make a solution of 50% by weight, and 1% of ultraviolet photoinitiator 2959 is added, at 30mW / cm 2 The point light source of light intensity was cured for 2 minutes, and the measured tensile ...

Embodiment 3

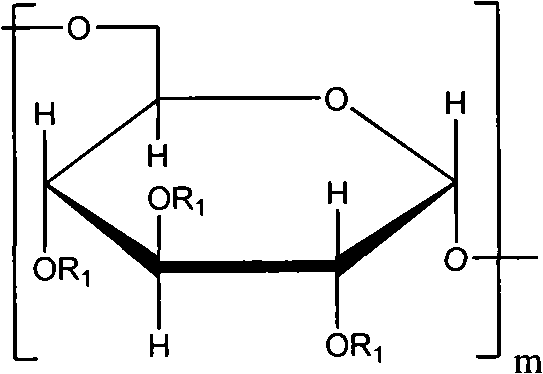

[0034] Dissolve 8 g of dextran with 250 ml of chloroform, put it into a reaction vessel after it is completely dissolved, and then add 8 drops of dibutyltin dilaurate as a catalyst. Then add 13 g of ethyl methacrylate isocyanate into 100 mL of dimethyl sulfoxide, drop it into the reaction vessel through a constant pressure dropping funnel under nitrogen atmosphere, stir vigorously, and heat in a water bath at 35°C. Use FTIR to monitor the reaction progress in real time, when 2267cm -1 If the peak does not disappear within 20 minutes, the reaction ends and the dropwise addition is stopped. The reaction product was added into deionized water, and the precipitate was filtered and washed several times to obtain the final product.

[0035] Product is diluted with dimethyl sulfoxide and is made into the solution of 75% by weight percentage, adds the ultraviolet photoinitiator 2959 of weight fraction 5%, at 30mW / cm 2 The point light source of light intensity was cured for 2 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com