Ethanol fermentation engineering bacteria capable of reducing fermentation byproduct

A technology of ethanol fermentation and engineering bacteria, applied in the directions of fermentation, microorganism-based methods, bacteria, etc., can solve problems such as affecting ethanol production, and achieve the effect of reducing the accumulation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of ethanol-resistant Escherichia coli ethanol fermentation engineering bacteria

[0026] A. Screening of Escherichia coli ethanol-resistant strain MG1655

[0027] Escherichia coli MG1655, JML09, BW25113, BL21, and BW25141 were cultured in LB medium, and after growing to the logarithmic phase, they were transferred to LB medium containing 4%, 6% ethanol for culture, (ethanol was filtered out through a 0.45 μm filter membrane) added to the LB medium after bacteria), 12h, 24h respectively measured OD in the liquid LB medium 600 The absorbance value was used to measure the difference in growth rate between screened strains. Compare OD 600 It was concluded that MG1655 was superior to other E. coli in ethanol tolerance.

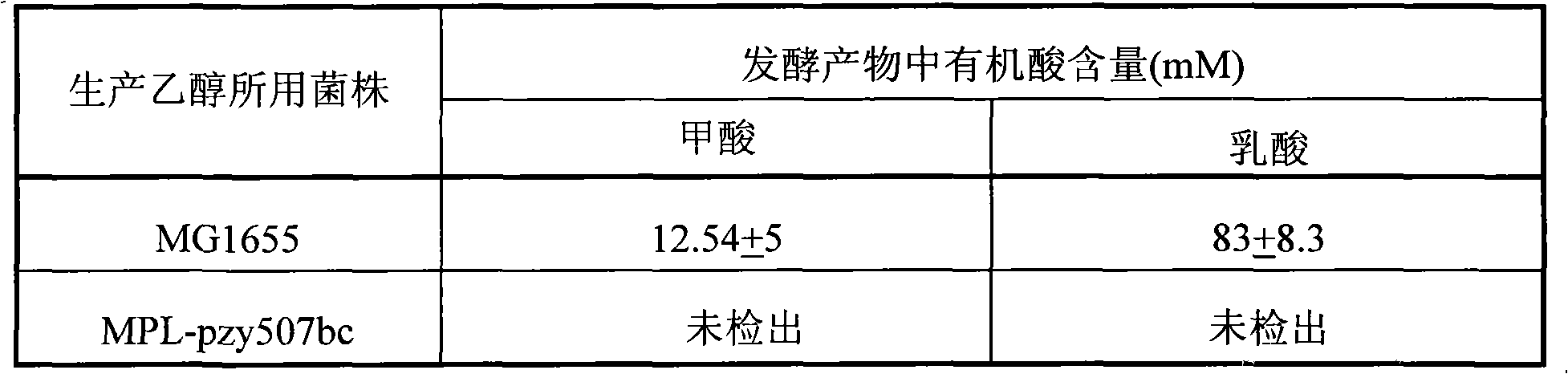

[0028] B. Screening of mutant strains of ethanol-producing pyruvate formate lyase gene and lactate dehydrogenase gene of Escherichia coli

[0029] Escherichia coli MG1655 was made into competent cells by using calcium chloride, t...

Embodiment 2

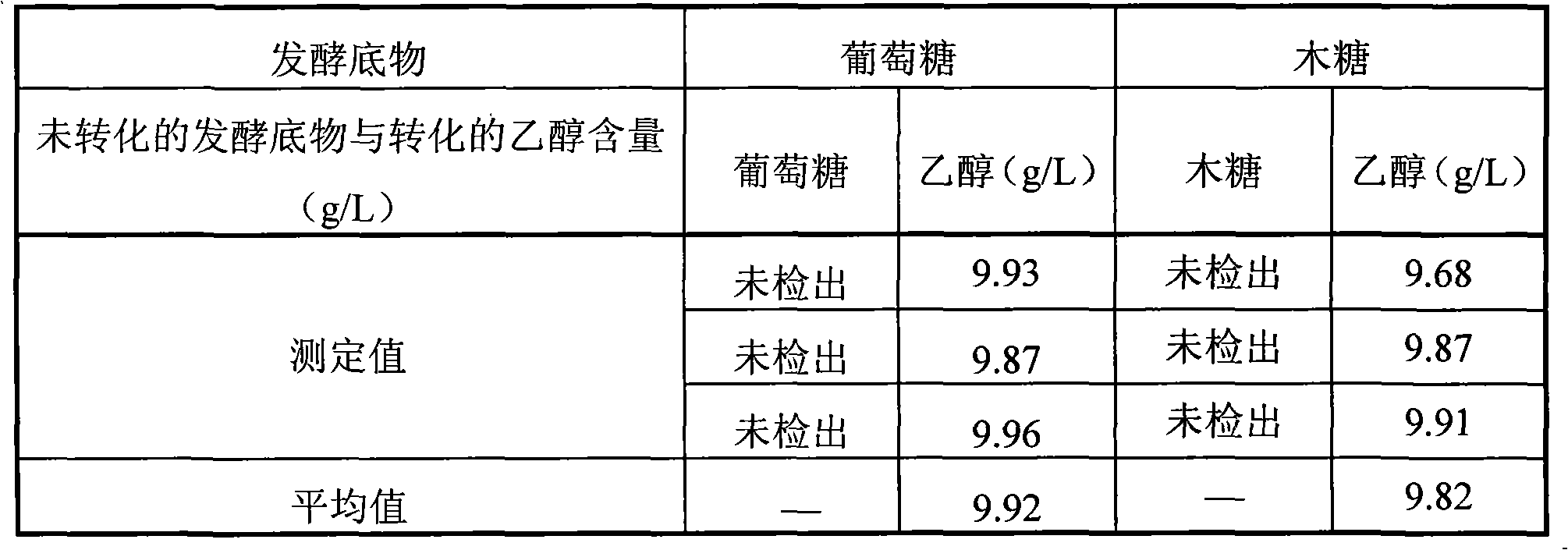

[0133] Example 2 Engineering strain MPL-pzy507bc fermentation to produce ethanol

[0134] 1. Culture conditions

[0135] 1. 1M9 medium, the composition is:

[0136] Glucose 2%, Na 2 HPO 4 ·7H 2 O 64g, KH 2 PO 4 15g, NaCl 2.5g, NH 4 Cl 5.0g, 121°C, 15min. 1mol / L MgSO 4 2mL, 1mol / L CaCl 2 0.1mL, final volume 1L;

[0137] Xylose 10% Na 2 HPO 4 ·7H 2 O 64g, KH 2 PO4 15g, NaCl 2.5g, NH 4 Cl 5.0g, 121°C, 15min. 1mol / L MgSO 4 2mL, 1mol / L CaCl 2 0.1mL, final volume 1L;

[0138] 1.2 Culture and fermentation conditions

[0139] Inoculate MPL-pZY507bc into M9 medium and culture to OD 600 =0.2 or so, add 1.0mM IPTG to induce, when MPL-pZY507bc grows to OD 600 = 1.0, the bacteria were collected by centrifugation, inoculated into the fermentation medium described in 1.1, and made OD after inoculation 600 The value is about 1.0, 37 ℃ anaerobic culture.

[0140] 2. Determination of residual sugar in fermentation broth

[0141] High-performance liquid chromatography was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com