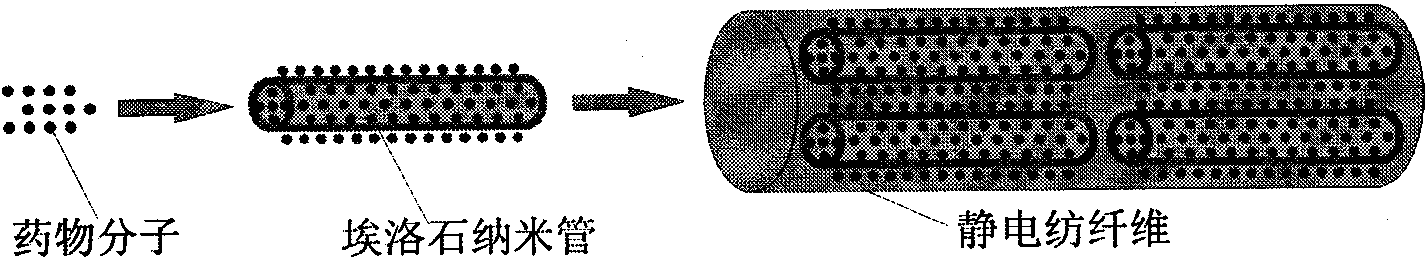

Preparation of TCH/HNTs/PLGA nanometer composite fibre medicine carrying system

A nanocomposite fiber and drug-loading system technology, which is applied in the field of preparation of TCH/HNTs/PLGA nanocomposite fiber drug-loading system, can solve the problems of not finding the mechanical properties of electrospun nanofiber mats, and achieve good drug sustained release effect, The effect of avoiding sudden release phenomenon and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take 100mg of the model drug TCH and add it to 100ml of phosphate buffered saline (PBS), heat and stir at 80-90°C for about 30 minutes to dissolve to obtain the TCH solution, until the solution is clear, cool to room temperature, and set aside;

[0046] Take 100mg of HNTs and mix with the above TCH solution, put it in an ultrasonic cleaner for 50min, so that HNTs can be evenly dispersed in the TCH solution;

[0047] Place the reagent bottle containing the mixed solution of TCH and HNTs in a vacuum drying oven with the open mouth, and vacuumize for 15 minutes under the condition of 0.085MPa until there are no more bubbles on the surface of the liquid; Vacuum again in the drying oven to completely remove the air between the inner cavity of the HNTs and the HNTs, so that TCH can be adsorbed to the surface of the HNTs and / or loaded into the inner cavity;

[0048] Transfer the solution in the reagent bottle to a centrifuge tube, centrifuge at 3000rpm for 25min, take out the ...

Embodiment 2

[0050] The supernatant obtained by centrifugation in Example 1 was diluted 10 times, and the absorbance of the TCH solution at 270 nm was tested with a UV spectrophotometer. According to the concentration-absorbance relationship curve calibrated with the TCH solution, the remaining HNTs after loading the drug can be calculated. The amount of TCH in the supernatant, then, the amount of TCH loaded on the HNTs can be calculated, and the drug loading efficiency (drug loading efficiency (%)=mass of TCH on HNTs / mass of HNTs) can be calculated.

Embodiment 3

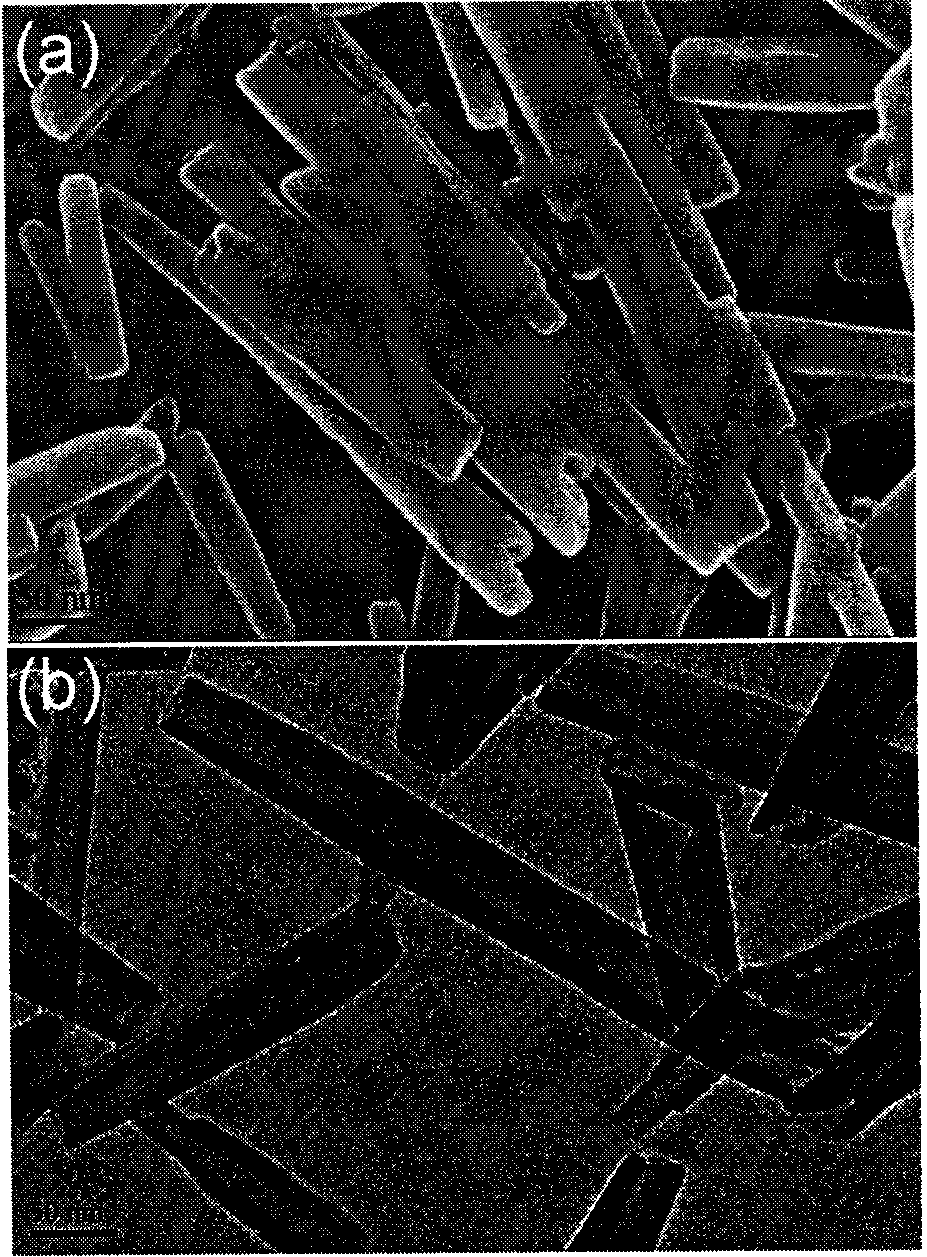

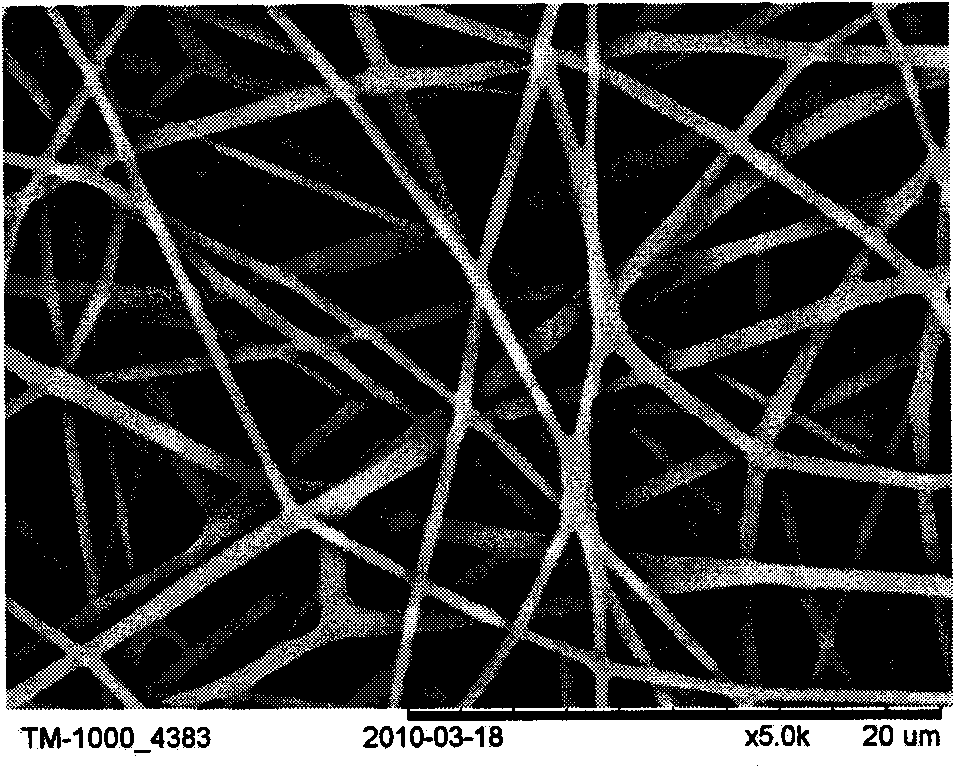

[0052] The PLGA of 1mg is dissolved in the TMF / DMF (3: 1) solvent of 4ml, is mixed with the solution that mass concentration percentage is 25%, leaves standstill overnight; Add HNTs powder into PLGA solution, ultrasonically disperse for 20min to prepare electrospinning solution, and then prepare nanofiber mat according to the conventional electrospinning method, wherein the receiving distance is 15cm, the voltage is 20kV, and the flow rate is 0.8ml / h. The composite nanofiber felt was dried in a vacuum oven for 48 hours, and then used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com