Silver-(titanium oxide)-zeolite adsorbent/decomposing material and process for production thereof

A manufacturing method and technology of titanium oxide, which are applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low synthesis efficiency and difficulty in synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] As Example 1, a method for synthesizing an Ag-titanium oxide-zeolite composite using pure reagents will be described.

[0035] Hereinafter, specific raw material compositions and reaction conditions are shown, but the present invention is not limited to such specific ranges.

[0036] In a solution containing 40 to 400 mg / ml of sodium silicate and 30 to 300 mg / ml of sodium aluminate, titanium oxide powder was added in a range of 1 to 90% by weight to prepare 3N sodium hydroxide and aged.

[0037] As the silicic acid source, in addition to sodium silicate, a reagent such as colloidal silica, or a material containing a silicon source that generates silicic acid in an aqueous solution such as sintered metakaolin can also be used. In addition, as an aluminum source, instead of sodium aluminate, a reagent such as aluminum hydroxide or an aluminum source that generates aluminum ions in an aqueous solution such as aluminum chips may be used. In short, a silicic acid source and...

Embodiment 2

[0047] As Example 2 of the production method, a method for producing an Ag-titanium oxide-zeolite composite using paper pulp (PS: Paper Sludge) as a zeolite raw material will be described.

[0048] Pulp is the discarded portion of a paper mill produced as sediment or suspended matter in the paper manufacturing process, or the sediment or suspended matter generated from the effluent of a paper mill. Pulp incineration ash is produced by incinerating pulp.

[0049] The main component of pulp incineration ash is silicic acid (SiO 2 ), alumina (Al 2 o 3 ), magnesium oxide (MgO), etc. These components are derived from fillers added to paper raw materials such as pulp during the papermaking process. As the filler, talc, calcium carbonate, titanium dioxide, aluminum hydroxide and the like can be used in addition to white clay such as kaolinite, clay, or clay. The proportions of these components in pulp or pulp incineration ash are about 10 to 40% by weight of silicic acid, 15 to ...

Embodiment 3

[0066] As Example 3, an Ag-titanium oxide-zeolite mixture was prepared.

[0067] As a raw material for a titanium oxide-zeolite mixture, titanium oxide powder (anatase type, particle size 20 nm) and zeolite crystal powder (Na-type faujasite type, particle size 3 μm) were mixed in a mortar at a weight ratio of 1:4. ).

[0068] As in Example 1, the titanium oxide-zeolite mixture thus prepared was impregnated with a solution containing sodium ions and silver ions to be substituted to obtain the desired Ag-titanium oxide-zeolite mixture.

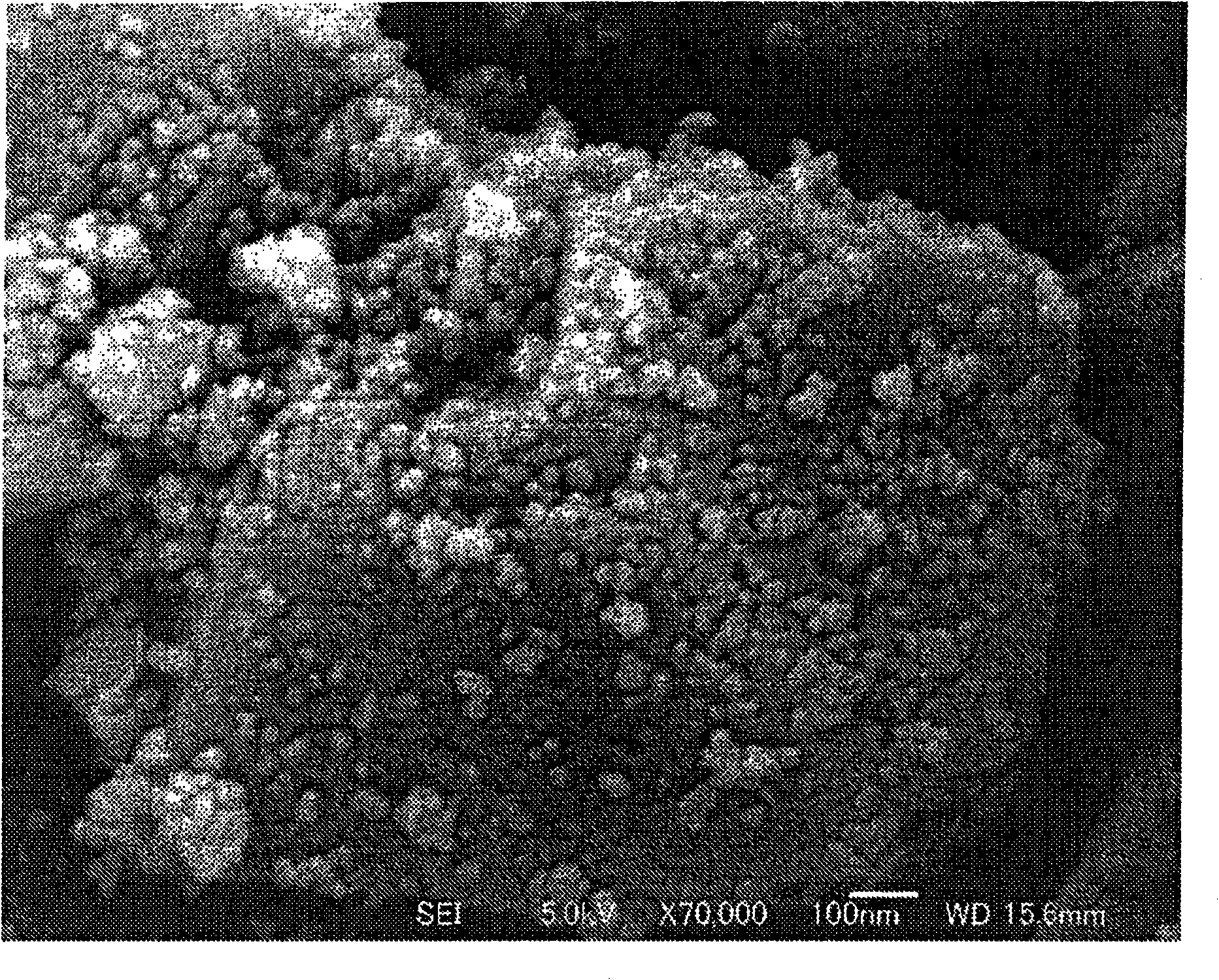

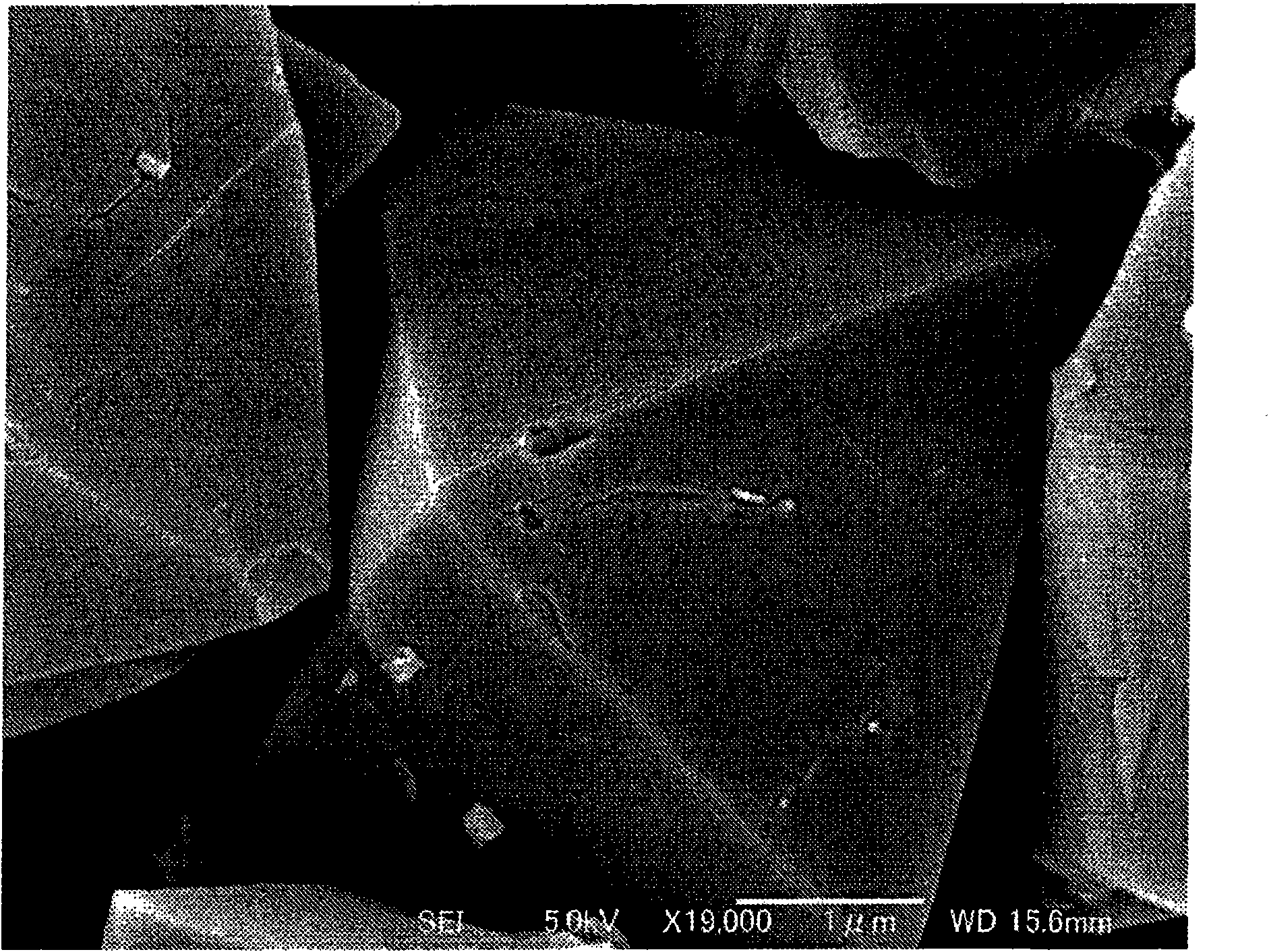

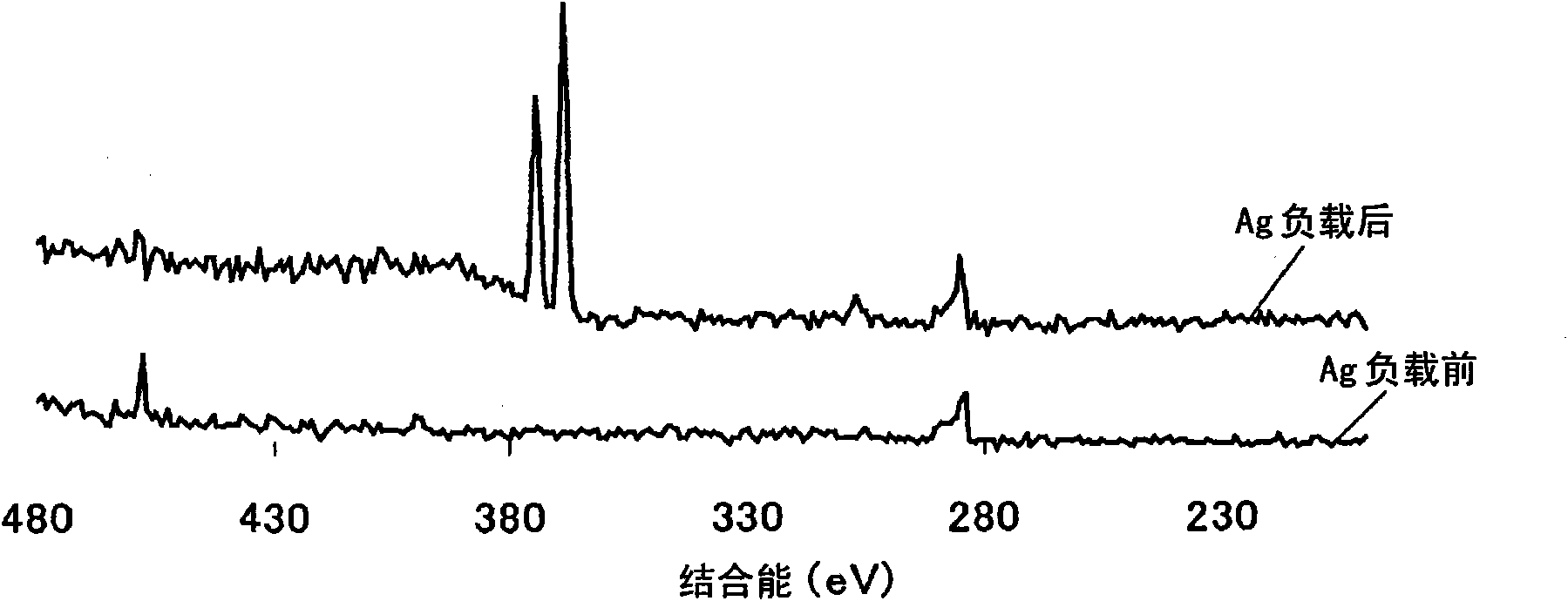

[0069] Figure 5 A scanning electron microscope image of the titanium oxide-zeolite mixture before silver-supporting in Example 3 is shown. according to Figure 5 From the image of , it can be seen that the fine particles of titanium oxide are in solid form, and are non-uniformly connected to the outer periphery of the zeolite crystal.

[0070] In order to determine the adsorption and decomposition properties of non-polar molecules of the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com