Method and device for producing methane by using dry anaerobic digestion for urban sludge and organic matter

A dry anaerobic and municipal sludge technology, applied in the field of solid waste recycling, can solve the problems of difficult gas overflow, difficult mass transfer, and difficult enrichment of methane bacteria, so as to facilitate enrichment, facilitate operation and management, and save The effect of temperature control on energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

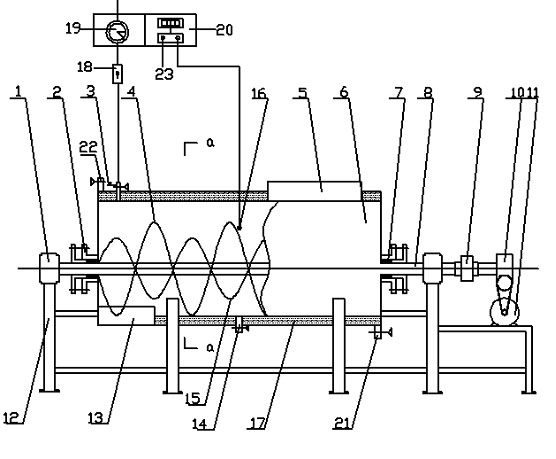

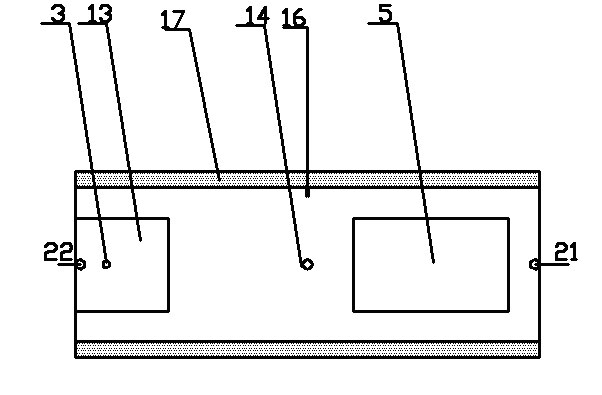

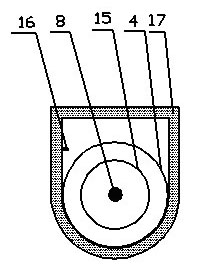

[0033] Such as Figure 1-3 As shown, the device is composed of a fermentation tank body, a stirring system, a temperature control and heat preservation system, and a control system; the fermentation tank body 6 lies on the support 12, the bearing and the bearing support 1 are fixed on the support 12, and the rotating shaft 8 passes through the fermentation Tank body 6, one end of the rotating shaft 8 is connected to the bearing and bearing support 1, the other end is connected to the coupling 9, the coupling 9 is connected to the transmission 10, the transmission 10 is connected to the motor 11; the fermentation tank body 6 is provided with a feeding port 5 and a discharge port 13. The sludge sampling port 14 and the gas sampling port 3, the gas enters the wet bulb gas flow meter 19 after the rotameter 18; the tank is equipped with a stirring system, which is composed of a rotating shaft 8, an outer spiral annular belt 4 and an inner spiral annular belt 15. , The outer spiral r...

Embodiment 2

[0036] Take 300L of dewatered sludge from sewage plant B, put it into the fermentation tank through the feed port 5, and mix it with the last batch of fermented biogas residue. At this time, the material height is about 5cm higher than the upper edge of the outer spiral belt 4; The moisture content of the material is 80.8%, the organic content is 56.2%, the C / N ratio is 9.8, and the material adhesion is 45g; the feed inlet 5 is sealed, the stirring speed is set to 12r / min, the motor switch is turned on, and the fermentation starts; start 3 Days later, the temperature of the material measured by the temperature display device is 34℃, and the wet gas flow meter shows the gas output as 20L; turn on the temperature control device, set the temperature to 35℃, adjust the stirring speed to 20r / min, and set the stirring motor to turn on for 1 hour / Stop operation for 1 hour; after 8 days of operation in this stage, the water content of the material measured from the sludge sampling por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com