Method and equipment for separating volatile organic matters from fermentation product in situ

A volatile, in-situ separation technology, applied in separation methods, biochemical equipment and methods, distillation separation, etc., can solve the problems of low gas stripping efficiency, large energy consumption of online separation devices, and large energy consumption, and achieve reduction Effect of treatment cost, reduction of separation cost, and improvement of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

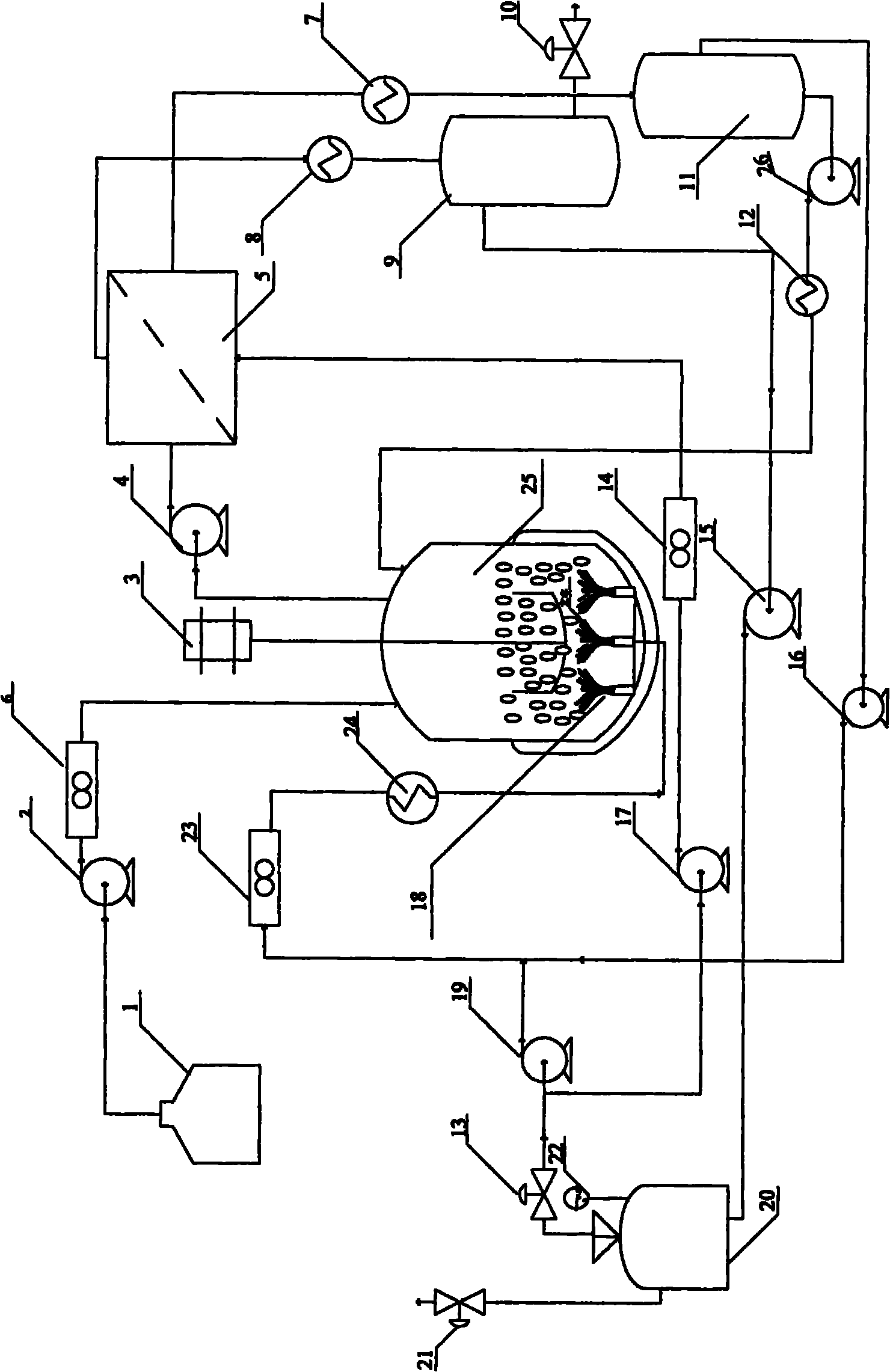

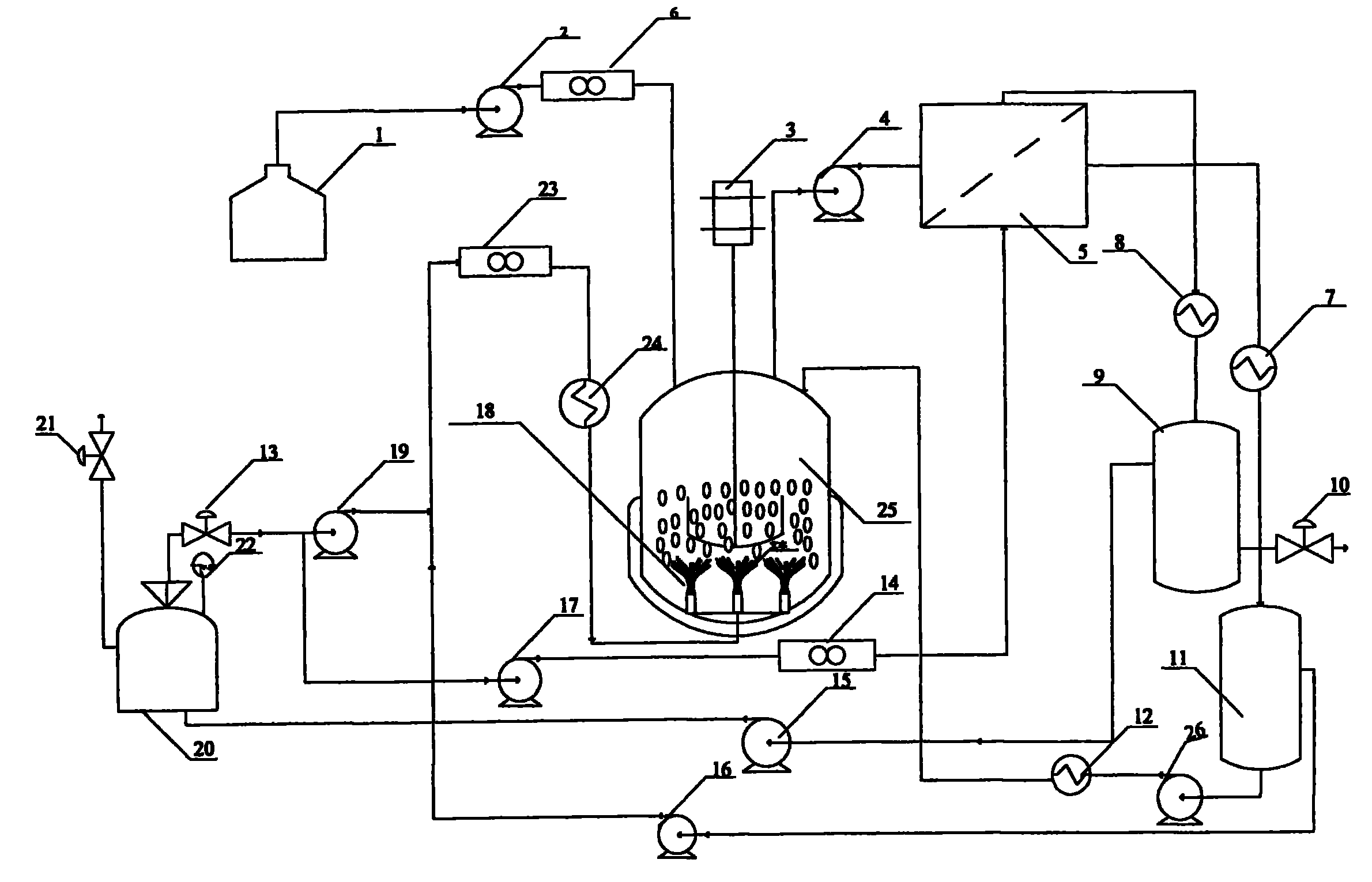

[0026] Example 1: Using starch as raw material for CO 2 and H 2 Preparation of Butanol-Acetone-Ethanol (ABE) by Mixed Gas Circulation Stripping / Steam Permeation In-Situ Separation Coupling Process

[0027] The starch raw material enters the fermentation process through liquefaction and saccharification. according to figure 1 Assemble equipment, adopt 2L fermentation tank, inoculate according to 5% (v / v) inoculum amount, make the culture volume of fermentation tank be 1L, fermentation temperature is controlled at 37 ℃, stirring speed 150r / min. When the fermentation is carried out to 20 hours (h), the concentration of butanol in the fermentation broth is 4-5g / l, the stirring is turned off, and the inert gas CO 2 and H 2 mixed gas (or CO 2 or N 2 ) to start air stripping, the ventilation rate is 3000ml / min. The mixed gas from the fermenter enters the steam permeation device, the temperature of the steam permeation device is controlled at 37°C, and the other side of the ste...

Embodiment 2

[0028] Example 2: Using starch as raw material for CO 2 Production of Ethanol by Circulating Gas Stripping / Steam Permeation In-Situ Separation Coupling Process

[0029] The starch raw material enters the fermentation process through liquefaction and saccharification process, according to figure 1 Assemble equipment, adopt 2L fermentation tank, inoculate according to 5% (v / v) inoculum amount, make the culture volume of fermentation tank be 1L, fermentation temperature is controlled at 35 ℃, stirring speed 150r / min. Fermentation is carried out to 24 o'clock, the concentration of ethanol in the fermented liquid is 70g / l, close stirring, feed inert gas CO 2 Start gas stripping, the ventilation rate is 3000ml / min. The mixed gas from the fermenter enters the steam permeation device, the temperature of the steam permeation device is controlled at 35°C, and the other side of the steam permeation device is filled with CO 2 Purge and dehydrate. The gas dehydrated by steam permeation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com