Polyvinyl chloride composite material and preparation method thereof

A technology of polyvinyl chloride and composite materials, applied in the field of polyvinyl chloride composite materials and its preparation, to achieve the effects of both toughness, good cold resistance, and expanded temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Raw material composition ratio is as follows:

[0035] 100 parts of polyvinyl chloride,

[0036] 25 parts of polyester thermoplastic polyurethane elastomer rubber (TPU),

[0037] Impact modifier MBS resin 12 parts,

[0038] 10 parts of nano active calcium carbonate,

[0039] 4 parts of calcium zinc stabilizer,

[0040] 2 parts epoxy soybean oil,

[0041] 2.5 parts of titanium dioxide,

[0042] 0.8 parts of stearic acid,

[0043] 0.3 parts of polyethylene wax.

[0044] The preparation method of polyvinyl chloride composite material comprises the following steps:

[0045] 1. Ingredients: Weigh all kinds of raw materials according to the above dosage.

[0046] 2. Mixing: first add polyvinyl chloride, nano-active calcium carbonate, stabilizer and lubricant into the high-speed mixer.

[0047] 3. High mixing: Start the high-speed mixer, and when the temperature reaches 85-95°C, add polyester thermoplastic polyurethane elastomer rubber (TPU) for pre-plasticization tre...

Embodiment 2

[0051] Raw material composition ratio is as follows:

[0052] 100 parts of polyvinyl chloride,

[0053] 25 parts of polyester thermoplastic polyurethane elastomer rubber (TPU),

[0054] Impact-resistant acrylate ACR401 10 parts,

[0055] 15 parts of light active calcium carbonate,

[0056] 5 parts of calcium stearate,

[0057] 2 parts of calcium zinc stabilizer,

[0058] 2 parts epoxy soybean oil,

[0059] Titanium dioxide 1.5 parts

[0060] 0.3 parts of polyethylene wax

[0061] 0.8 parts of stearic acid.

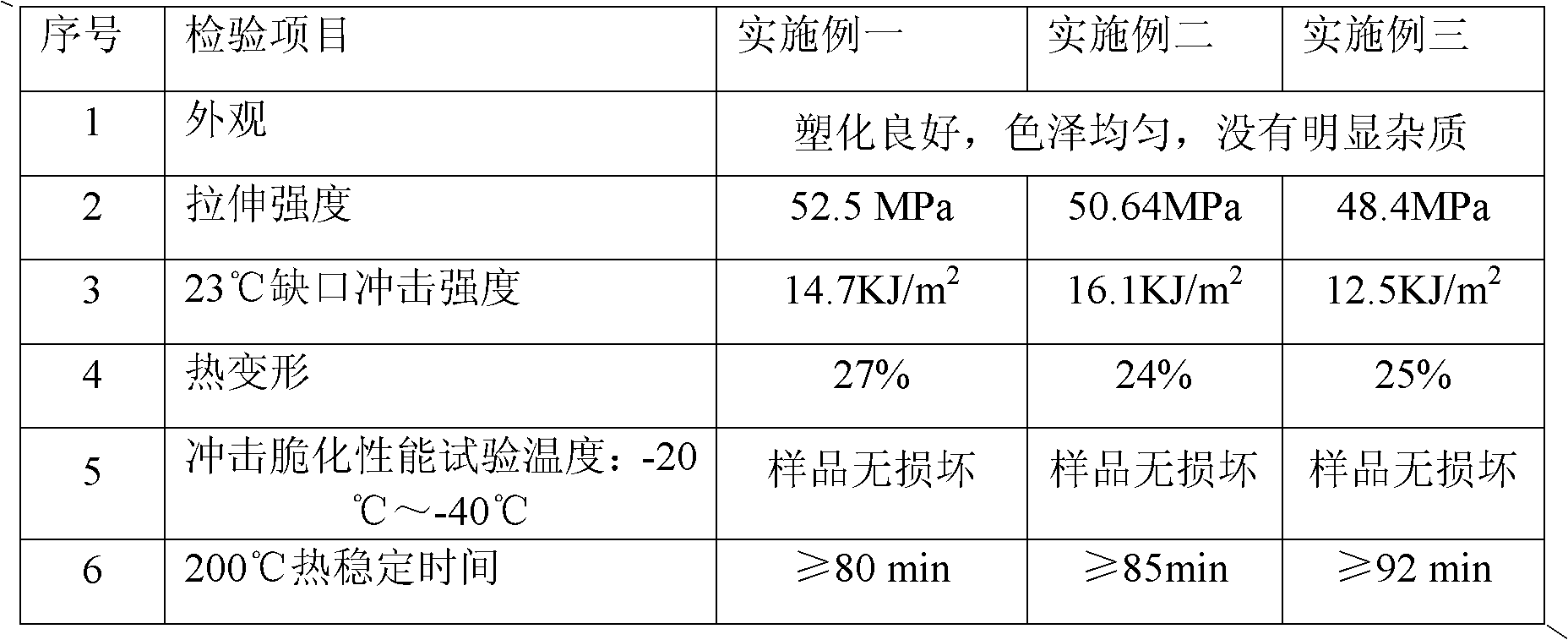

[0062] Its preparation process is with embodiment one. Its main physical properties are listed in Table 1.

Embodiment 3

[0064] Raw material composition ratio is as follows:

[0065] 125 parts of polyvinyl chloride,

[0066] 30 parts of polyester thermoplastic polyurethane elastomer rubber (TPU),

[0067] Impact modifier ethylene-vinyl acetate copolymer EVA15 parts,

[0068] 10 parts of nano active calcium carbonate,

[0069] 5 parts of barium stearate,

[0070] 2 parts of calcium zinc stabilizer,

[0071] 2 parts epoxy soybean oil,

[0072] 1.5 parts of titanium dioxide,

[0073] 0.3 parts of polyethylene wax,

[0074] 0.8 parts of stearic acid.

[0075] Its preparation process is with embodiment one. Its main physical properties are listed in Table 1.

[0076] Table 1

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com