Recombinant lactobacillus rhamnosus engineering strain and preparation method thereof

A technology of Lactobacillus rhamnosus and engineering strains, which is applied in the field of recombinant Lactobacillus rhamnosus engineering strains and their preparation to achieve the effect of improving antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

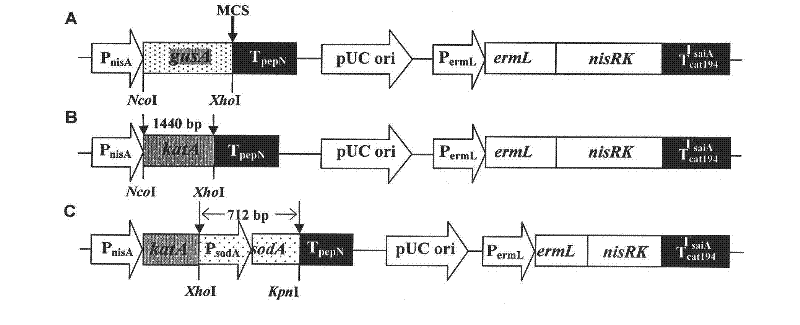

[0025] Embodiment 1 carries the construction of the plasmid vector of purpose gene katA

[0026] 1.1 Genomic DNA extraction of Lactobacillus sake

[0027] The genome was extracted using a bacterial genome DNA extraction kit (Tiangen Biochemical Technology (Beijing) Co., Ltd.), the method is as follows:

[0028] (1) Take 5ml of Lactobacillus sake cultured to the logarithmic phase, centrifuge at 12000rpm for 1 minute, discard the supernatant, add 200μl TES to resuspend once, centrifuge at 12000rpm for 1 minute, and suck off the supernatant as much as possible;

[0029] (2) Add 180 μl lysozyme (20mg / ml), and treat in a water bath at 37°C for 1 hour;

[0030] (3) Add 20 μl RNase (10mg / ml), shake slightly for 15 seconds, and place at room temperature for 5 minutes;

[0031] (4) Add 20 μl proteinase K solution and mix gently;

[0032] (5) Add 220 μl buffer GB, shake for 15 seconds, treat in a 70°C water bath for 10 minutes, and briefly centrifuge to remove water droplets on the t...

Embodiment 2

[0074] Embodiment 2 carries the construction of the plasmid vector of purpose gene katA and sodA

[0075] 2.1 Genomic DNA extraction of Streptococcus thermophilus

[0076] Method is with embodiment 1.

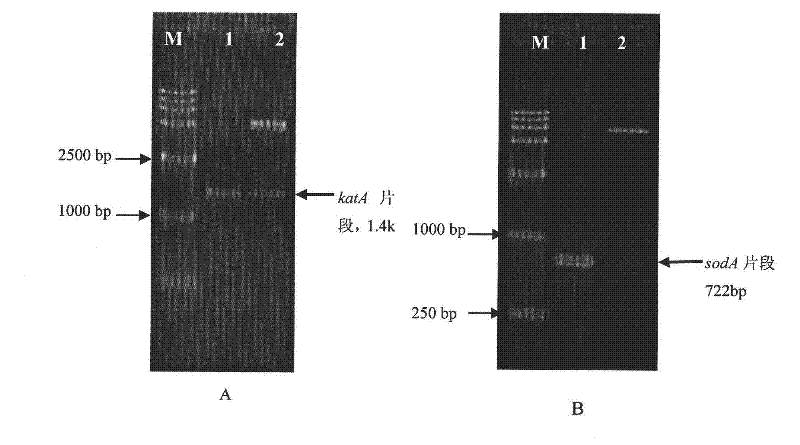

[0077] 2.2PCR amplification of catalase gene fragment sodA

[0078] Upstream primer: 5'-CCG CTCGAG CAAGATTTTGTAAG-3'

[0079] Downstream primer: 5'-GG GGTACC TGAGGATGATTCTAGAC-3'.

[0080] Xho I and Kpn I restriction sites were respectively introduced into the upstream and downstream primers, that is, the underlined part in the sequence.

[0081] The PCR program is as follows:

[0082] Component Addition (unit: μl)

[0083] Genomic DNA of Streptococcus thermophilus 1

[0084] Upstream primer (10μM) 0.5

[0085] Downstream primer (10μM) 0.5

[0086] dNTPs (10mM) 0.5

[0087] Ex Taq enzyme 0.5

[0088] 10× Reaction Buffer 2

[0089] Sterile double distilled water 15

[0090] The PCR reaction conditions are as follows:

[0091] Pre-denaturation at 95°C for 5min, d...

Embodiment 3

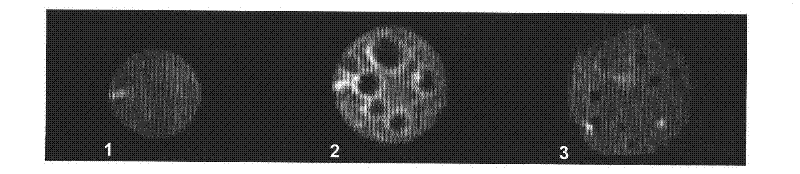

[0105] Example 3 Preparation of recombinant Lactobacillus rhamnosus engineering strain

[0106] 3.1 Preparation of Lactobacillus rhamnosus competent

[0107] Culture Lactobacillus rhamnosus with MRSS (MRS, 0.3M sucrose, 1% glycine (W / W)) medium and grow to OD 600 =0.4~0.6, take 10ml of bacterial liquid, centrifuge at 6000rpm, 4°C for 8min, collect bacterial cells; add 2ml of rinse solution (0.3M sucrose, 1mM MgCl 2 ) resuspended twice, centrifuged at 6000rpm at 4°C for 8min, discarded the supernatant; added 2ml of 30% (W / W) PEG-1500 resuspended cells, centrifuged at 6000rpm at 4°C for 10min, discarded the supernatant, and washed with 200μl of 30% Use after resuspension in PEG-1500.

[0108] 3.2 Electrotransformation of Lactobacillus rhamnosus with recombinant plasmid

[0109] Take 40 μl of Lactobacillus rhamnosus competent cells, mix with 2 μl of recombinant plasmid pSIPCS, transfer to a 2mm electroporation cup, use Bio-Rad Gene Pulser Xcell TM Type electric conversion ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com