Surface pretreatment solution and pretreatment method used for bonding magnesium alloys

A surface pretreatment, magnesium alloy technology, applied in the bonding method of surface pretreatment, metal material coating process, etc., can solve the problem of low shear strength of bonded joints, achieve good treatment effect, eliminate pollution, reduce Effect of joint strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

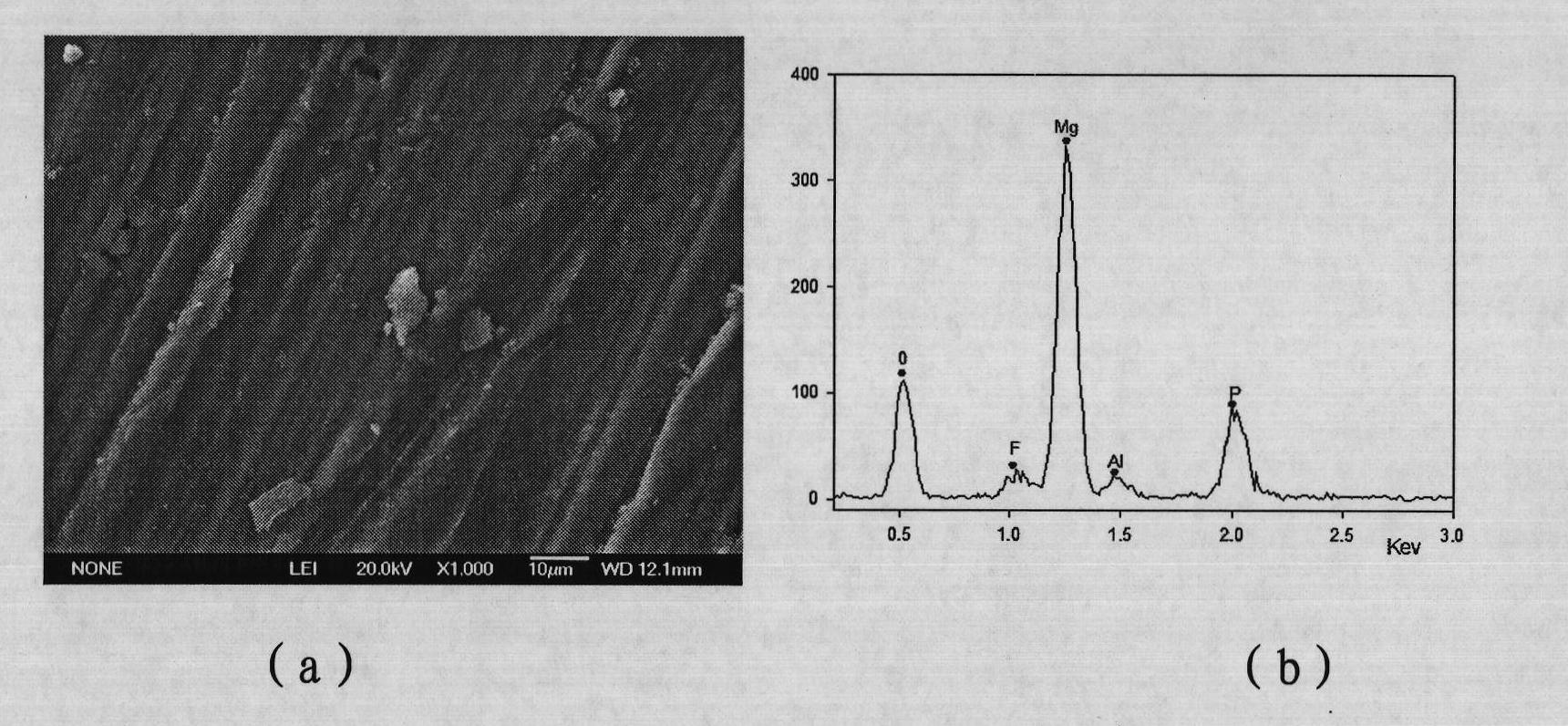

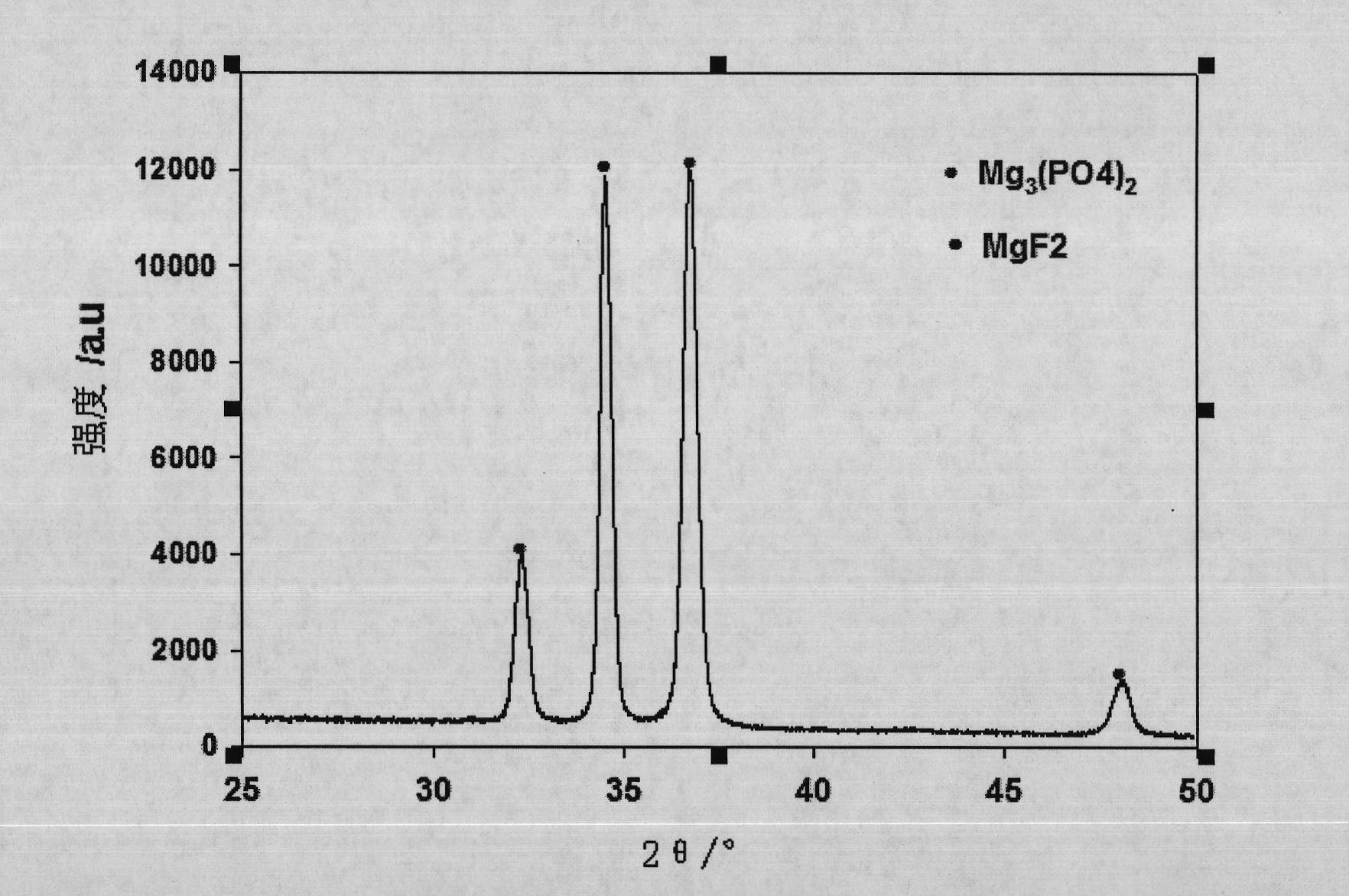

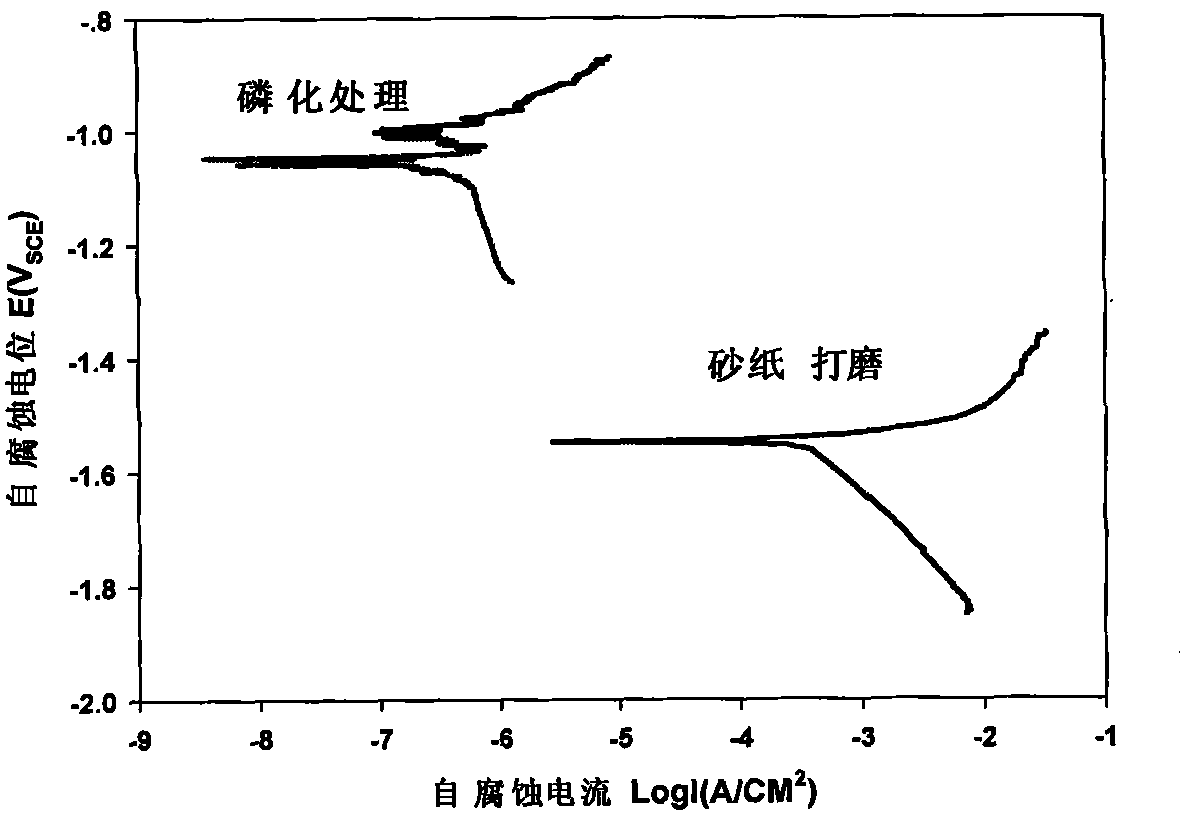

[0040] Using 2mm thickness AZ31 magnesium alloy plate. Two treatment processes were adopted, and the first process was sandpaper grinding process as a comparison process. The sample was first cleaned with acetone, and then 100 # Grinding with sandpaper, the roughness Ra is 3.8 μm.

[0041] Process two adopts the pretreatment process of the present invention, and concrete processing steps are:

[0042] 1) cleaning with acetone;

[0043] 2) Grinding with 800# sandpaper, the roughness Ra is 1.2μm;

[0044] 3) Alkali washing: Alkali washing at 70°C for 2 minutes. The composition of alkaline washing liquid is:

[0045] Sodium hydroxide: 15g / L; Sodium phosphate: 40g / L; Sodium silicate: 15g / L; Sodium carbonate: 15g / L; Sodium dodecylbenzenesulfonate: 1g / L.

[0046] 4) Surface pretreatment: soak in the pretreatment solution for 3 minutes at a temperature of 70°C.

[0047] The composition of the pretreatment liquid is:

[0048] Sodium dihydrogen phosphate 15g / L; composite accele...

Embodiment 2-6

[0055] The shape, size and treatment method of the sample are the same as those in Example 1. The concentration of each component of the pretreatment solution used is shown in Table 1, and the bonding strength is shown in Table 2.

[0056]

[0057] Table 2

[0058]

[0059] The adhesives used were purchased from Henkel Company and Dow Chemical Company in the United States.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com