Method for preparing barium sulfite by using sulfur dioxide waste gas

A technology of sulfur dioxide and barium sulfite, applied in chemical instruments and methods, calcium/strontium/barium sulfite, separation methods, etc., can solve problems such as endangering crop growth, polluting the environment, wasting resources, etc., and achieves significant social benefits and Economic benefits, simple process and production equipment, and the effect of eliminating sulfur dioxide gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

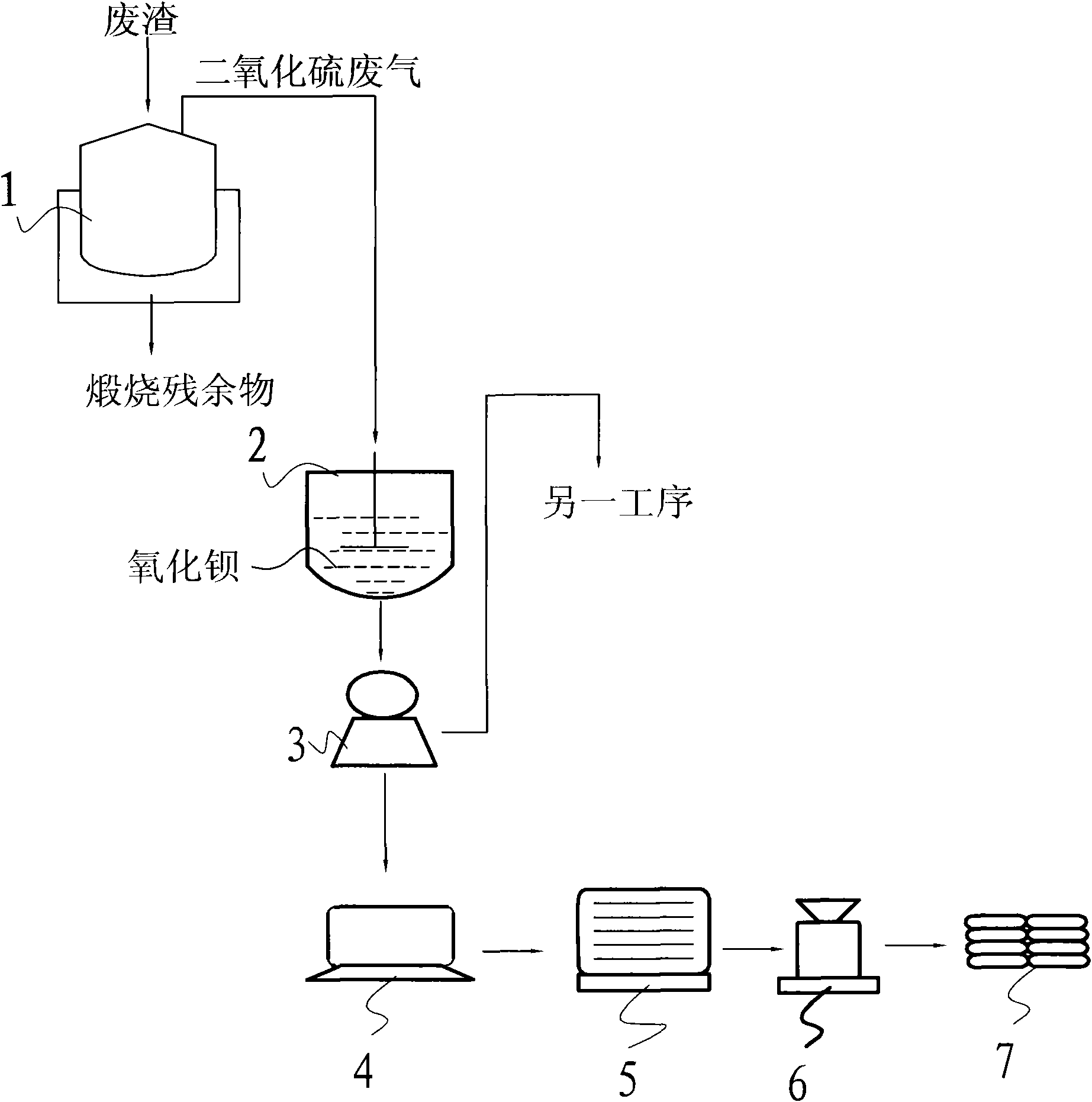

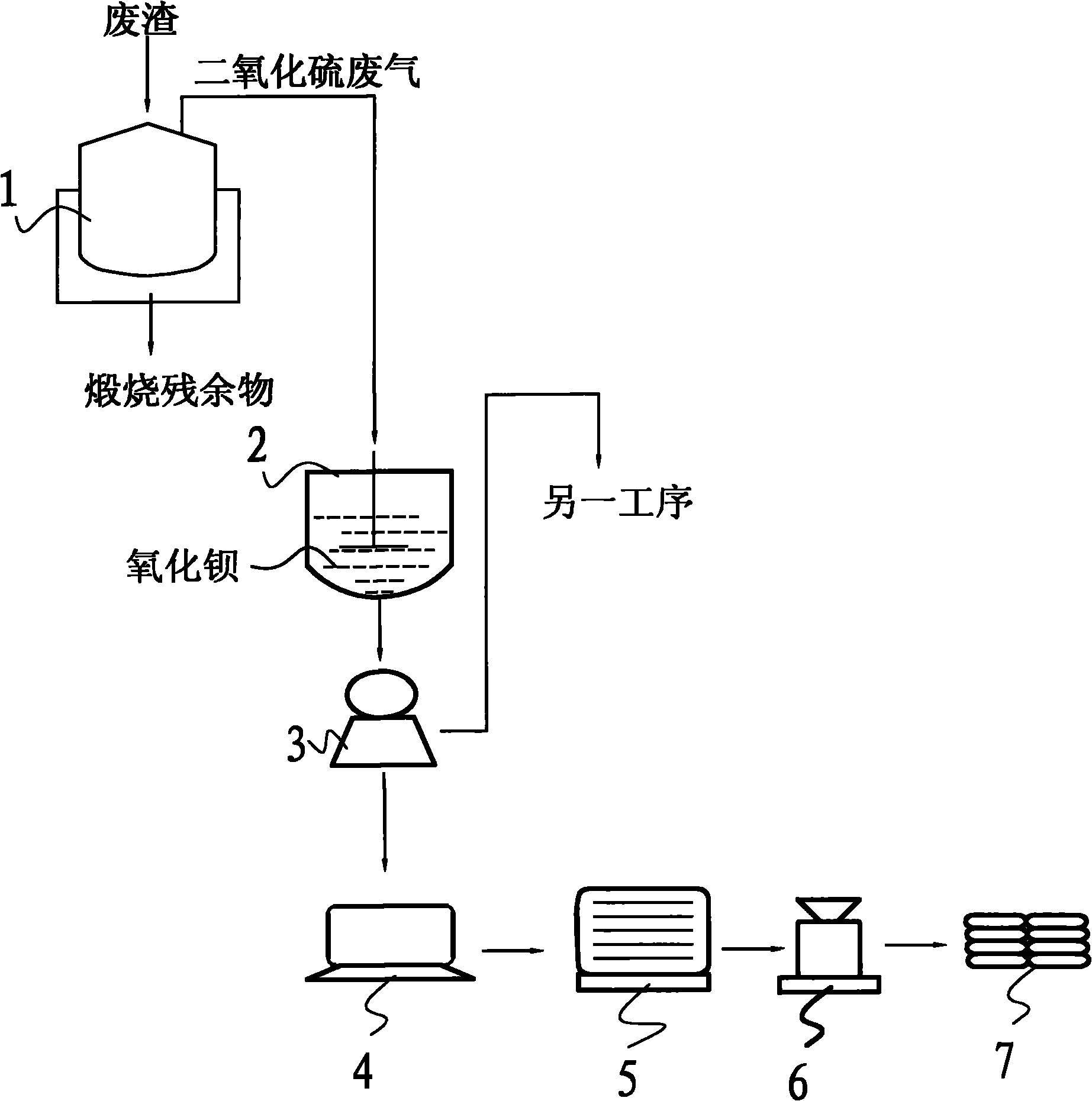

[0020] A method for preparing barium sulfite from sulfur dioxide waste gas, including the following preparation steps:

[0021] Step A: Transfer the waste slag produced by the preparation of lithopone to the electric arc furnace 1 for calcination, and the remaining solids after the calcination are discharged for use;

[0022] Step B: Into the reactor 2 containing the barium oxide solution, sulfur dioxide gas is introduced at a pure mass ratio of sulfur dioxide to barium oxide of 1:0.25, and the stirrer in the reactor 2 is slowly started to perform a chemical reaction; wherein the barium oxide The mass concentration of the solution is 20%; the calculation is based on a pure 600kg barium oxide solution; that is, the actual barium oxide that reacts with sulfur dioxide gas is 120kg;

[0023] Step C, filtering the reaction product obtained in step B with a suction filter 3;

[0024] Step D: Pass the filter cake obtained by filtering in step C through the scrubber 4, the dryer 5 and the pul...

Embodiment 2

[0026] A method for preparing barium sulfite from sulfur dioxide waste gas, including the following preparation steps:

[0027] Step A: Transfer the waste slag produced by the preparation of lithopone to the electric arc furnace 1 for calcination, and the remaining solids after the calcination are discharged for use;

[0028] Step B. Into the reactor 2 containing the barium oxide solution, sulfur dioxide gas is introduced at a pure mass ratio of sulfur dioxide to barium oxide of 1:0.25, and the stirrer in the reactor 3 is slowly started to perform a chemical reaction; wherein the barium oxide The mass concentration of the solution is 30%; the calculation is based on a pure 600kg barium oxide solution; that is, the actual barium oxide reacting with sulfur dioxide gas is 180kg;

[0029] Step C, filtering the reaction product obtained in step B with a suction filter 3;

[0030] Step D: Pass the filter cake obtained by the filtration in step C through the scrubber 4, the dryer 5 and the p...

Embodiment 3

[0032] A method for preparing barium sulfite from sulfur dioxide waste gas, including the following preparation steps:

[0033] Step A: Transfer the waste slag produced by the preparation of lithopone to the electric arc furnace 1 for calcination, and the remaining solids after the calcination are discharged for use;

[0034] Step B. Into the reactor 2 containing the barium oxide solution, pass sulfur dioxide gas at a pure mass ratio of sulfur dioxide to barium oxide of 1:0.65, and slowly start the stirrer in the reactor 2 to make a chemical reaction; wherein the barium oxide The mass concentration of the solution is 50%; the calculation is calculated based on the pure 600kg barium oxide solution; that is, the actual barium oxide reacting with the sulfur dioxide gas is 300kg;

[0035] Step C, filtering the reaction product obtained in step B with a suction filter 3;

[0036] Step D: Pass the filter cake obtained by filtration in step C through a scrubber 4, a dryer 5 and a pulverizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com