Organic-inorganic compound fertilizer

A compound fertilizer and inorganic fertilizer technology, applied in the direction of organic fertilizer, fertilizer mixture, bio-organic part treatment, etc., can solve the problems of aggravating the accumulation of harmful substances in the degree of soil compaction, the decline of agricultural product quality, and the health hazards of humans and animals, so as to meet the requirements of crop growth. demand, increased availability, and improved soil nutrient status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

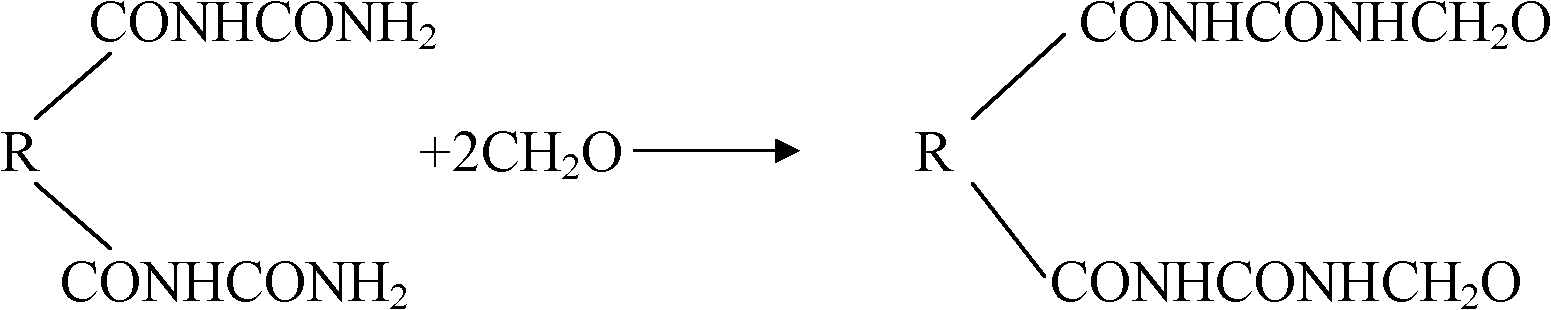

Method used

Image

Examples

Embodiment 1

[0049] The sum of nitrogen, phosphorus and potassium content ≥ 25%: formula N-P 2 o 5 -K 2 O is 11-5-9

[0050] Specific proportions: lignite nitrated humic acid 250-350kg, attapulgite soil powder 110-180kg, urea 180-230kg, potassium chloride 90-160kg;

[0051] Granulation process: use two ball forming machines in series to granulate, the material making temperature is 55-60 ℃, and the return material ratio is 1:0.3.

Embodiment 2

[0053] The sum of nitrogen, phosphorus and potassium content ≥ 30%: formula N-P 2 o 5 -K 2 O is 15-8-7

[0054] Specific proportions: lignite nitrated humic acid 200-280kg, kaolin 15-70kg, urea 190-270kg, chicken manure 15-60kg, potassium chloride 70-140kg;

[0055] Process: use two ball forming machines in series to granulate, the material making temperature is 55-60 ℃, and the return material ratio is 1:0.3.

Embodiment 3

[0057] The sum of nitrogen, phosphorus and potassium content ≥ 45%: formula N-P 2 o 5 -K 2 O for 20-12-13

[0058] Specific proportions: lignite nitrated humic ammonium salt 150-190kg, ammonium dihydrogen phosphate 180-260kg, urea 340-430kg, kaolin 9-13kg, potassium chloride 190-250kg, ammonium sulfate 25-50kg.

[0059] Granulation process: Before granulation, use refined lignite to nitrify humic acid ammonium salt, mix with urea and water in a mass ratio of 3.1:0.9:1, add salt (ammonium dihydrogen phosphate, potassium chloride, ammonium sulfate) and adjust the viscosity agent to 50°C to make a slurry matrix. When urea powder is added to the rotating granulator during granulation, the prepared slurry matrix is sprayed so that nitrohumic acid is evenly wrapped around the urea granules, and then quickly dried and sieved to obtain nitrate Humic acid urea complex compound fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com