Composite conductor application of carbon nano tube fiber and preparation method thereof

A carbon nanotube fiber and composite wire technology, which is applied in the manufacturing of carbon-silicon compound conductors, metal/alloy conductors, cables/conductors, etc., can solve the problems of wire fracture failure, complex production process, poor strength and toughness, etc. Simple, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

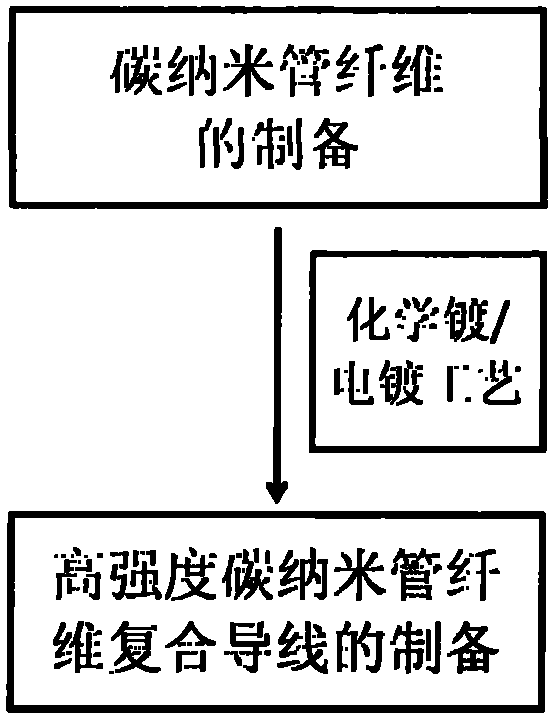

[0034] Such as figure 2 As shown, the carbon nanotube fiber composite wire of the present invention uses carbon nanotube fibers as the main body, and a uniform metal coating is obtained on the surface of the carbon nanotube fibers through an electroless plating process. The specific steps include two parts: carbon nanotube fiber preparation and fiber chemical plating.

[0035] First of all, electron beam evaporation is used, with thermal oxidation of SiO in 2 inches 2 A uniform Fe film was deposited on the Si wafer as a catalyst for the growth of carbon nanotube arrays. Then it was placed in a quartz tube furnace with a diameter of 3 inches, and the spinnable carbon nanotube array was prepared by using thermal chemical vapor deposition technology under the growth condition of 700 °C using acetylene gas as the carbon source gas, and the array height was 400 μm. Thereafter, a carbon nanotube film with a fixed width of 3 mm is uniformly pulled out from the spinnable array by d...

Embodiment 2

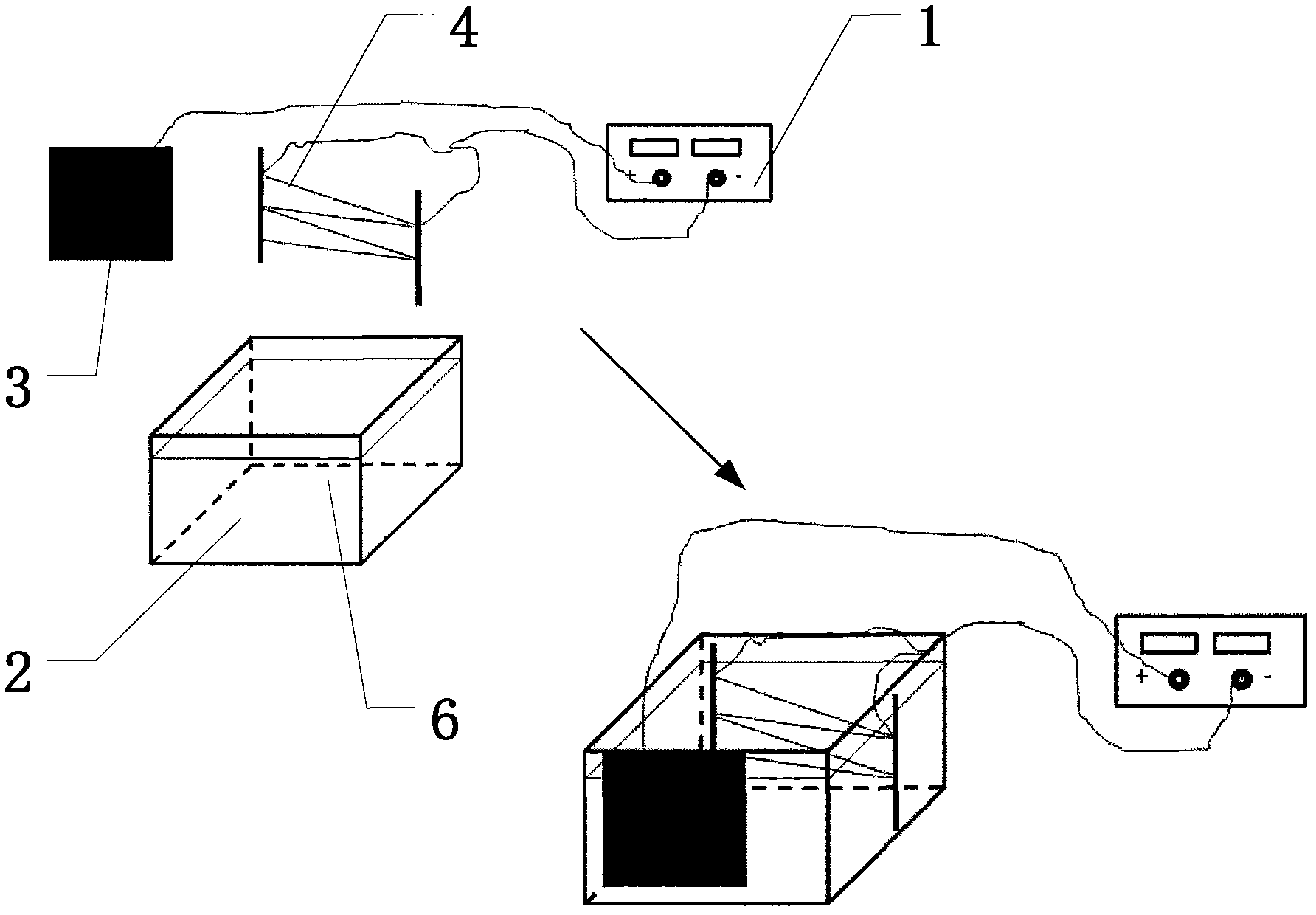

[0038] Such as image 3 As shown, the carbon nanotube composite wire according to the present invention uses carbon nanotube fibers as the body, and a uniform metal coating is obtained on the surface of the carbon nanotube fibers through an electroplating process. The specific steps include two parts: carbon nanotube fiber preparation and fiber electroplating.

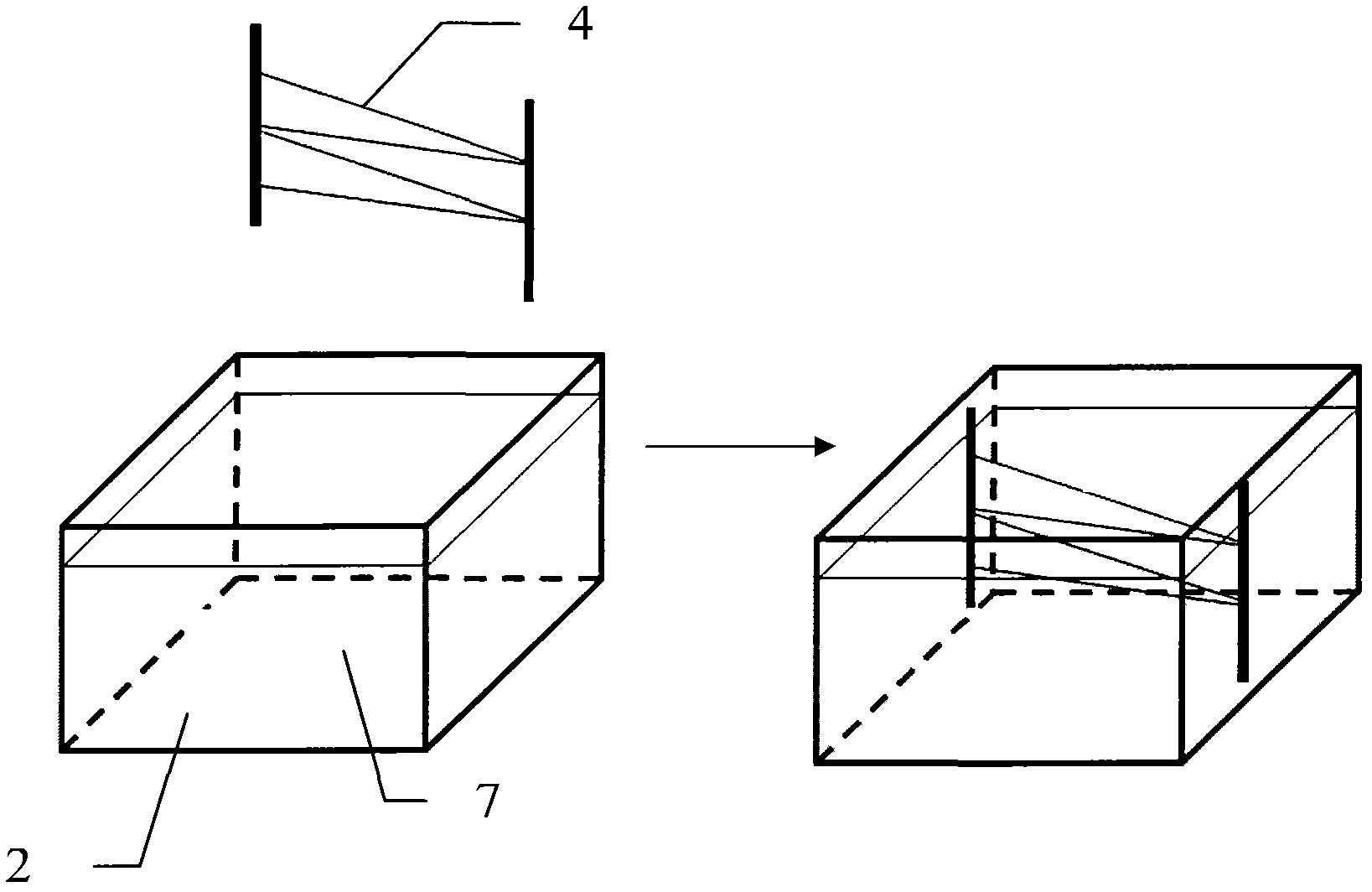

[0039] The preparation method of carbon nanotube fiber material refers to specific example 1. The prepared carbon nanotube fibers with a diameter of 12 μm were fixed on a PVC plate, and one end of the carbon nanotube fibers was connected to an electrode with conductive silver glue. Using CuSO 4 The solution is an electroplating solution. Place the prepared electroplating solution on a magnetic heating stirrer, and keep the temperature of the electroplating solution at 40-45° C. by means of stirring and heating. Place the carbon nanotube fiber pre-fixed on the PVC plate in the plating solution, connect the electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com