Nitrogen and phosphorus absorbing agent

An adsorbent, nitrogen and phosphorus technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as difficult separation, unsatisfactory adsorption effect, harsh regeneration conditions, etc., and achieve simple and good repeatability in the preparation process and post-treatment process Use performance, reduce the effect of mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

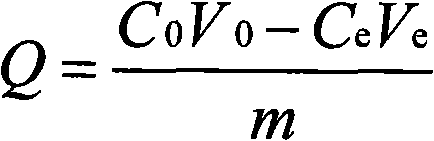

Method used

Image

Examples

Embodiment 1

[0023] Stir 100 grams of attapulgite clay with 1000 mL of 1mol / L ferric chloride solution at room temperature for 2 hours, add 2 grams of chitosan, and after dissolving, add an aqueous solution containing 80 grams of itaconic acid and 20 grams of acrylic acid, and then add 200 mL of ethanol aqueous solution, stirred evenly, added 0.5 g of N,N'-methylenebisacrylamide, stirred for 30 minutes, then added 0.2 g of ammonium persulfate. The temperature was raised to 70° C. for 3 hours. After the reaction is completed, carry out cross-linking treatment with aluminum chloride, filter and bake at 70°C to constant weight for packaging.

Embodiment 2

[0025] Stir 80 grams of attapulgite clay with 800 mL of 0.1mol / L sulfuric acid solution at room temperature for 2 hours, add 2 grams of polyvinyl alcohol, heat up to dissolve, add an aqueous solution containing 20 grams of methacrylic acid and 80 grams of acrylic acid, and then add 250 mL of ethanol aqueous solution, stir evenly, add 1 g of N,N'-methylenebisacrylamide, stir for 30 minutes, then add 3 g of ammonium persulfate. The temperature was raised to 70° C. for 3 hours. After the reaction is completed, it is cross-linked with calcium chloride, filtered and dried at 70°C until it is packed at a constant weight.

Embodiment 3

[0027] Stir 120 grams of attapulgite clay with 900 mL of 2.5 grams of hexadecyltrimethylammonium bromide solution at room temperature for 2 hours, add 3 grams of humic acid, and add 10 grams of methyl methacrylate after stirring evenly. and an aqueous solution of 80 grams of acrylic acid, and then 250 mL of an aqueous solution of isopropanol was added, after stirring evenly, 2 grams of N,N'-methylenebisacrylamide was added, and after stirring for 30 minutes, 5 grams of potassium persulfate was added. The temperature was raised to 70° C. for 3 hours. After the reaction is completed, it is cross-linked with calcium chloride, filtered and dried at 70°C until it is packed at a constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com