Method for preparing agricultural potassium sulfate from potassium-rich rock

A technology for potassium-rich rock and potassium sulfate is applied in the field of preparing agricultural potassium sulfate, which can solve the problems of lack of water-soluble potassium ore resources, dependence on imports of potassium sulfate raw materials, and limited production capacity of potassium sulfate, and achieves significant economic benefits and product cost. The effect of low and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

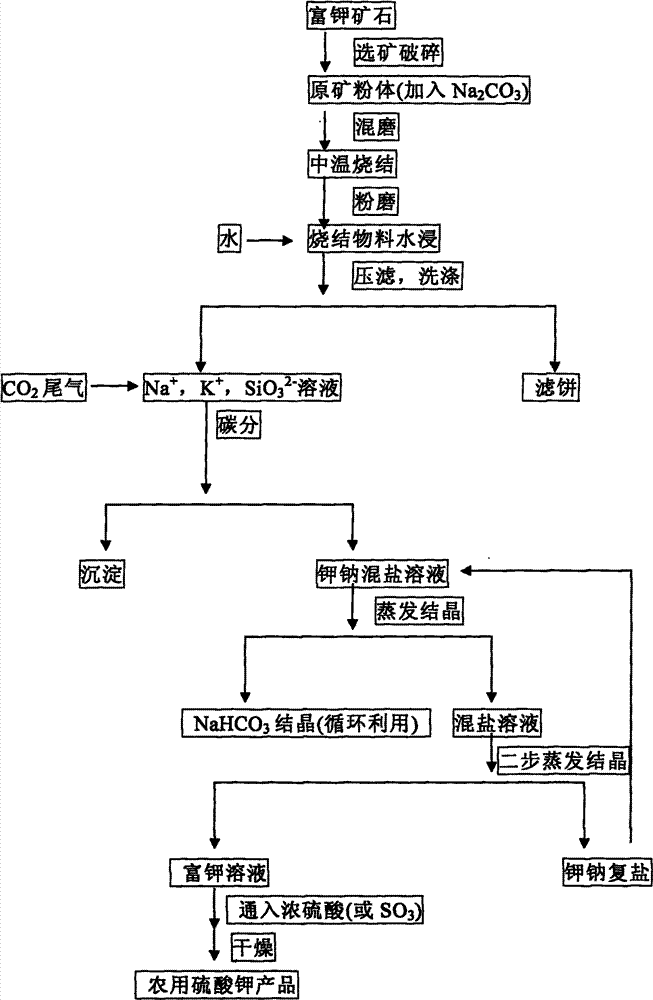

[0025] Such as figure 1 As shown, it is required to grind the potash feldspar powder to -200 mesh, mix it thoroughly with sodium carbonate in a weight ratio of 1:1.5, and calcinate in a calciner with a calcining temperature of 800°C and a calcining time of 2 hours , To obtain off-white to light green semi-sintered clinker powder. At the same time, a gas recovery device is installed above the calcination furnace to reduce the CO produced during the calcination process. 2 The tail gas is recovered, and then recycled through the scrubber to remove dust and purify.

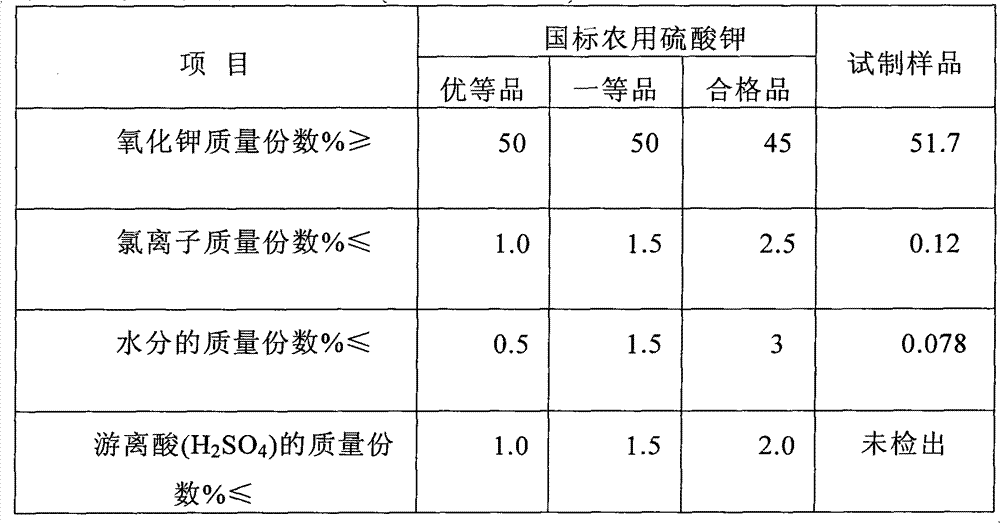

[0026] After the above-mentioned clinker powder is further ground, water is added according to the weight of the powder to water ratio of 1:8 and fully stirred until the pH value of the mother liquor is 8.5. The aluminum in the mother liquor is composed of aluminosilicate colloid. The form precipitates, and the potassium-containing mother liquor is obtained after filtration. The potassium-containing mother liquor passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com