Oil tea peel extract containing oil tea peel polyphenol as well as preparation method and application of oil tea peel extract

A technology of camellia oleifera peel and extraction method, which is applied in application, animal feed, animal feed, etc., to achieve the effects of reducing pollution, simple and easy production process, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Example of the preparation method of Camellia oleifera peel extract of the present invention (ultrasonic treatment is used in the extraction step)

[0031] (1) First, crush the fresh camellia oleifera peel and pass through a 50-mesh sieve.

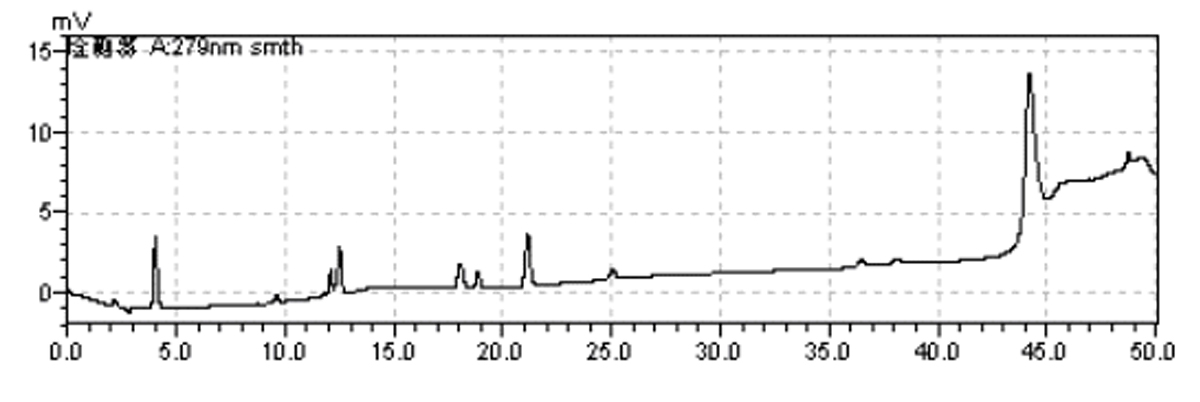

[0032] (2) Extraction with methanol, the amount of per gram of camellia oleifera peel powder is 18 mL, the pH value is adjusted to 3.0 with 5 wt% hydrochloric acid, the extraction temperature is 30°C, and the extraction time is 4 h. Extraction system, ultrasonic power 500W, ultrasonic action time 30 min. After the leaching was completed, centrifuge at 5000 rpm for 15 min, and take the supernatant.

[0033] (3) The polyphenol extract from camellia oleifera peel was separated and purified by nanomembrane. The conditions for membrane separation are as follows: a nanometer ultrafiltration membrane system is used, the operating pressure is 0.8 MPa, and the operating temperature is 30°C. Extract the concentrated solution, rec...

Embodiment 2

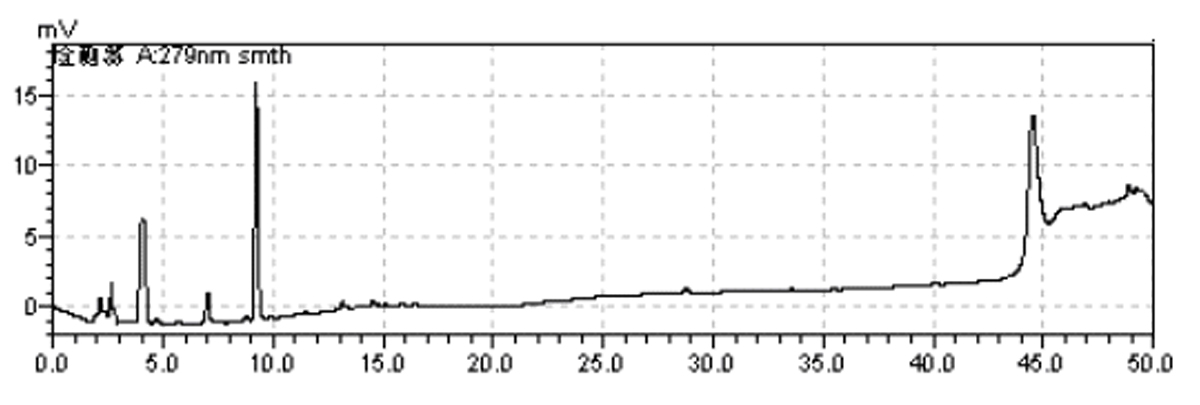

[0038] Example 2 Example of the preparation method of Camellia oleifera peel extract of the present invention (ultrasonic treatment is not used in the extraction step)

[0039] (1) First, the fresh camellia oleifera peel is pulverized with a knife mill, and passed through a 50-mesh sieve.

[0040] (2) Extract with methanol, the amount of per gram of camellia oleifera peel powder is 18 mL, the pH value is adjusted to 3.0 with 5% hydrochloric acid, the extraction temperature is 30°C, and the extraction time is 4 h. After the leaching was completed, centrifuge at 5000 rpm for 15 min, and take the supernatant.

[0041] (3) The polyphenol extract from camellia oleifera peel was separated and purified by nanomembrane. The conditions for membrane separation are as follows: a nanometer ultrafiltration membrane system is used, the operating pressure is 0.8 MPa, and the operating temperature is 30°C. Extract the concentrated solution, recover the organic solvent, and the concentration...

Embodiment 3

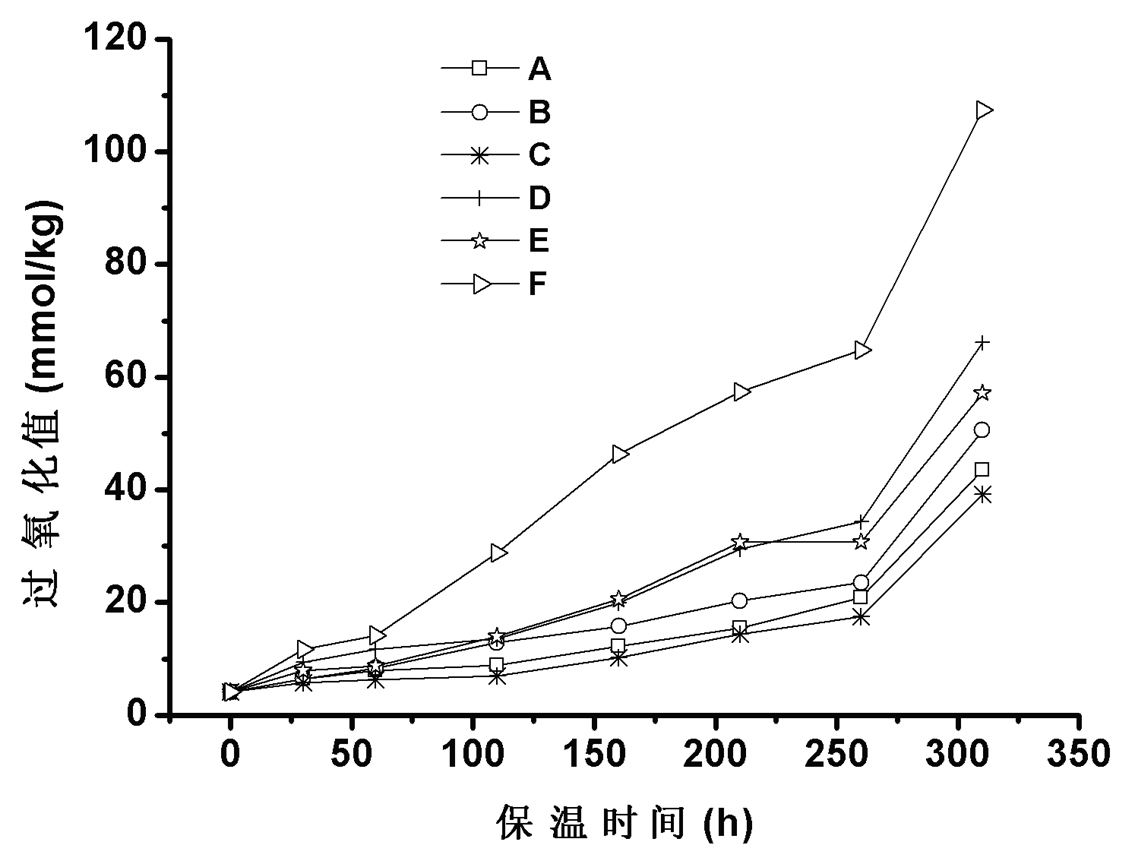

[0045] Example 3 Optimum Experimental Example of Emulsifier Addition in Feed Additives

[0046] The test was divided into six groups. Camellia oleifera peel extract extract containing polyphenols of camellia oleifera peel was mixed with emulsifier monoglyceride in different mass ratios, and stirred evenly while mixing, and the mixed system was placed in a 500mL beaker. Each group was formulated as follows:

[0047] Test group A: Camellia oleifera peel extract extract containing polyphenols from camellia oleifera peel was mixed with emulsifier monoglyceride at a mass ratio of 1:3, added to soybean oil to fully dissolve it, so that the polyphenols contained in camellia oleifera peel The quality of Camellia oleifera peel extract extract is 1% of the volume of soybean oil, add water equivalent to 2 v% of the soybean oil mixture, and stir evenly;

[0048] Test group B: Camellia oleifera peel extract extract containing polyphenols from camellia oleifera peel was mixed with emulsifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com