Roast tail gas treatment method in production of catalytic cracking catalyst

A catalytic cracking and treatment method technology, applied in the field of roasting tail gas treatment process, can solve the problems of high investment cost, high waste discharge, no recycling, etc., and achieve the effect of high heat recovery rate, less sewage discharge and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to accompanying drawing and specific embodiment:

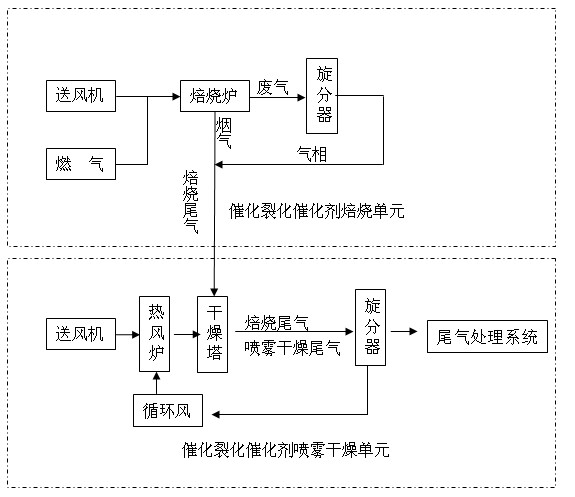

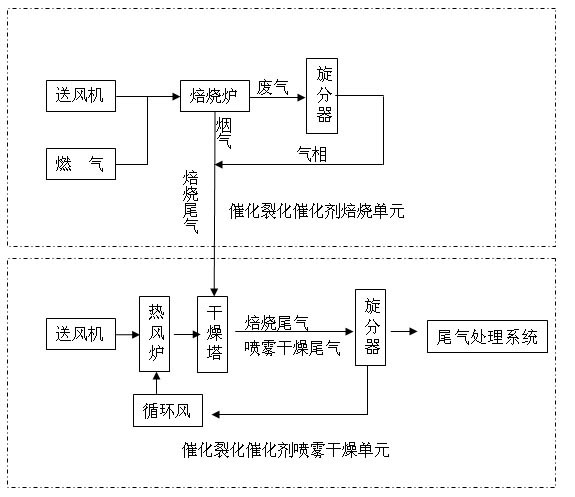

[0014] according to figure 1 In the process shown in the figure, the gas is fully mixed with the air sent by the blower, and is burned in the roaster to produce flue gas above 600°C. At the same time, the catalyst is raised from 130°C to 550°C in the roaster to generate a large amount of waste gas. After the gas and solid are separated by the cyclone, the gas phase and flue gas are directly introduced into the drying tower of the negative pressure system of the cracking catalyst spray drying unit, which is used as the drying heat source. Part of it is used for heat recovery and mixed with catalytic cracking catalyst spray-dried tail gas, and the gas phase is separated by a cyclone and then sent to the tail gas treatment system for treatment. In this way, a high heat recovery rate can be ensured, and the negative pressure of the catalytic cracking catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com