Method for preparing polyether surfactant

A surfactant and polyether technology, applied in the field of preparation of polyether surfactants, can solve the problems of restricting large-scale production and commercial application, strict reaction conditions, etc., and achieve safe use, simple synthesis, and high monomer conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

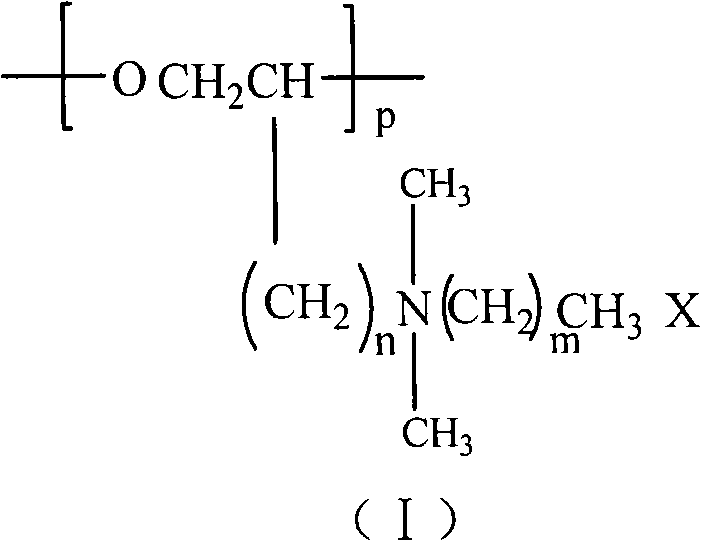

[0029] Embodiment 1, the preparation of polyether surfactant

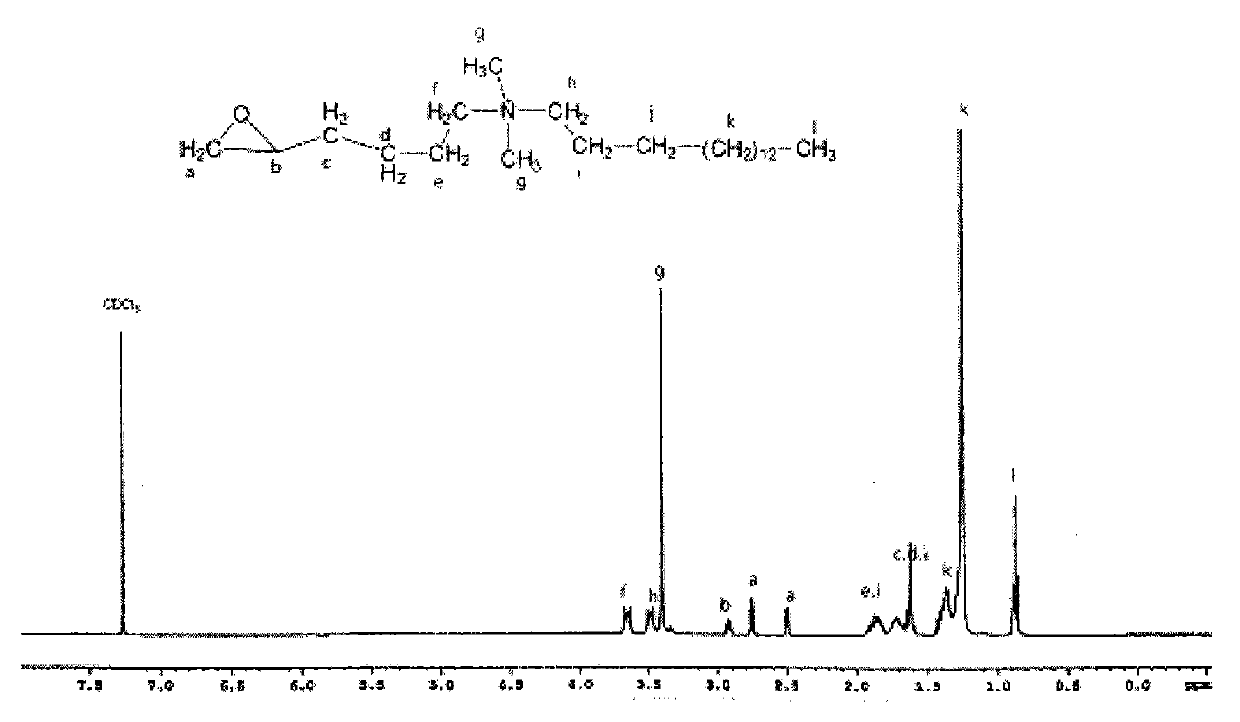

[0030] (1) Preparation of N, N-dimethylhexadecyl-1,2-epoxyhexyl ammonium bromide

[0031] Weigh 2.71g (0.01mol) of N,N-dimethylhexadecylamine (the molar ratio of it to 6-bromo-1,2-epoxyhexane is 1:1.1), pour 20mL of anhydrous acetone into Equipped with a condenser tube, a constant pressure dropping funnel and a 150mL three-neck flask with a stirring bar, then put it into a constant temperature water bath at 20°C, start stirring and stir evenly. Weigh 1.97g (0.011mol) of 6-bromo-1,2-epoxyhexane (the mass and number ratio of it and acetone is 1:7) and pour it into a constant pressure dropping funnel, then add 6-bromo-1 , 2-Epoxyhexane was slowly dropped into the three-necked flask, and the drop was completed within 15 minutes, and the reaction was carried out for 12 hours. After the reaction was completed, it was concentrated and suspended to dryness, and washed several times with anhydrous ether, then put it in a ...

Embodiment 2

[0034] Embodiment 2, the preparation of polyether surfactant

[0035] (1) Preparation of N, N-dimethylhexadecyl-1,2-epoxybutyl ammonium bromide

[0036] Weigh 5.39g (0.02mol) of N,N-dimethylhexadecylamine (the molar ratio of 4-bromo-1,2-epoxybutane is 1:1), pour 25mL of acetone into a condenser Tube, constant pressure dropping funnel and a 150mL three-necked flask with a stirring bar, and then put it in a constant temperature water bath at 70°C, start stirring and stir evenly. Weigh 3.02g (0.02mol) of 4-bromo-1,2-epoxybutane (the mass fraction ratio of it and acetone is 1:6) and pour it into a constant pressure dropping funnel, then pour 4-bromo-1 , 2-epoxybutane was slowly dropped into the three-necked bottle, and the drop was completed within 15 minutes, and the reaction was 24 hours. After the reaction was completed, it was concentrated and suspended to dryness, and washed several times with anhydrous ether, then put it in a vacuum drying oven to dry for 48 hours at a dry...

Embodiment 3

[0039] Embodiment 3, the preparation of polyether surfactant

[0040] (1) Preparation of N, N-dimethylhexadecyl-1,2-epoxybutyl ammonium bromide

[0041] The experimental procedure is the same as the step (1) of Example 1, except that the quality of N,N-dimethylhexadecylamine is 2.71g (0.01mol), 6-bromo-1,2-epoxyhexane The mass of N,N-dimethylhexadecyl-1,2-epoxyhexylammonium bromide was 3.92g, and the yield was 88%.

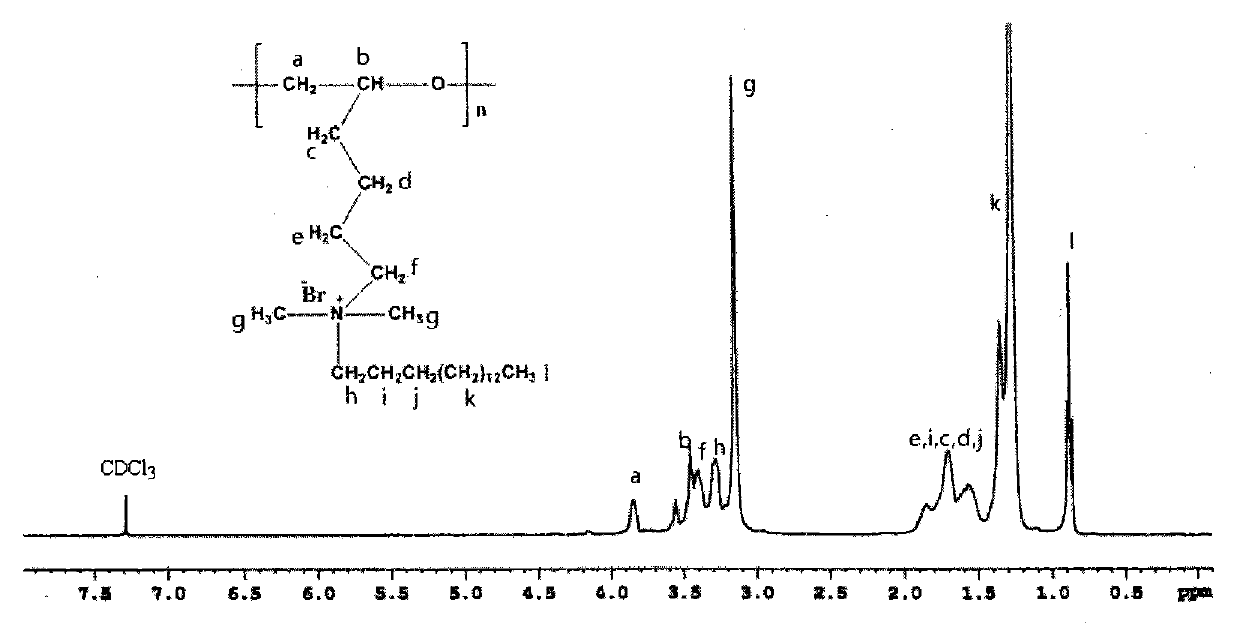

[0042] (2) Preparation of polyether surfactant

[0043] The experimental procedure is the same as the step (2) of Example 1, except that the quality of N,N-methylhexadecyl-1,2-epoxyhexyl ammonium bromide is 1.12g (0.0025mol), and the initiator three The amount of boron fluoride ether is 0.001 mol, and the obtained light yellow solid is the polyether surfactant, the mass is 0.99 g, the degree of polymerization is 6, and the yield is greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com