Melt/solid-phase polycondensation preparation method of polylactic acid material with high molecular weight and high crystallinity

A polylactic acid material and high molecular weight technology, which is applied in the field of melt/solid phase polycondensation preparation of high molecular weight and high crystallinity polylactic acid, can solve the problem that the reaction rate is difficult to meet the requirements of industrialization, the energy consumption of secondary melt blending is high, and the polycondensation process can be improved. Reduce the cost of lactic acid and other issues, achieve the effect of shortening the melt polycondensation time, increasing the solid phase polycondensation rate, and shortening the dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 300 grams of 90% lactic acid aqueous solution and 1.08 grams of p-toluenesulfonic acid (0.4% by weight of lactic acid weight) in a 500 milliliter four-necked flask, vacuumize to an absolute pressure of 15000 Pa, and heat to 140 ° C for 2 hours of reaction Then, evacuate to an absolute pressure of 400Pa, and heat to 160°C, react for 2 hours, and the number-average degree of polymerization of the product is 20.

[0034] Add 1.08 grams of stannous chloride dihydrate (the weight percent content of lactic acid weight is 0.4%), install a reflux condenser additionally, control the reflux condenser jacket water temperature 83 ℃, vacuumize to an absolute pressure of 200Pa, and heat the material to 180 °C, reacted for 4 hours, cooled, pulverized, and sieved to obtain polylactic acid prepolymer particles with a weight average molecular weight of 21,000.

[0035] Take 5 grams of a sample with a particle size of 0.4-0.5 mm, and crystallize at 70° C. for 1 hour in a nitrogen atmo...

Embodiment 2

[0038] Add 300 grams of 90% lactic acid aqueous solution and 1.08 grams of p-toluenesulfonic acid (0.4% by weight of lactic acid weight) in a 500 milliliter four-necked flask, vacuumize to an absolute pressure of 14000 Pa, and heat to 130 ° C for 2 hours of reaction Then, evacuate to an absolute pressure of 400Pa, and heat to 150°C, react for 2 hours, and the number-average degree of polymerization of the product is 13.

[0039] Add 1.08 grams of stannous chloride dihydrate (the weight percent content of lactic acid weight is 0.4%), install a reflux condenser additionally, control the reflux condenser jacket water temperature 83 ℃, vacuumize to an absolute pressure of 200Pa, and heat the material to 180 °C, reacted for 10 hours, cooled, crushed, and sieved to obtain polylactic acid prepolymer particles with a weight average molecular weight of 42,000.

[0040] Take 5 grams of a sample with a particle size of 0.4-0.5 mm, and crystallize at 70° C. for 1 hour in a nitrogen atmosp...

Embodiment 3

[0043] Add 300 grams of 90% lactic acid aqueous solution and 1.08 grams of p-toluenesulfonic acid (0.4% by weight of lactic acid weight) in a 500 milliliter four-necked flask, vacuumize to an absolute pressure of 15000 Pa, and heat to 150 ° C for 1 hour Then, evacuate to an absolute pressure of 300Pa, and heat to 170°C, react for 2 hours, and the number-average degree of polymerization of the product is 27.

[0044] Add 1.08 grams of tin protochloride dihydrate (the weight percent content of lactic acid weight is 0.4%), install a reflux condenser additionally, control the reflux condenser jacket water temperature 83 ℃, vacuumize to an absolute pressure of 100Pa, and heat the material to 180 ℃, reacted for 4 hours, cooled, crushed, and sieved to obtain polylactic acid prepolymer particles with a weight average molecular weight of 23,000.

[0045] Take 5 grams of a sample with a particle size of 0.4-0.5 mm, and crystallize at 90° C. for 1 hour in a nitrogen atmosphere.

[0046]...

PUM

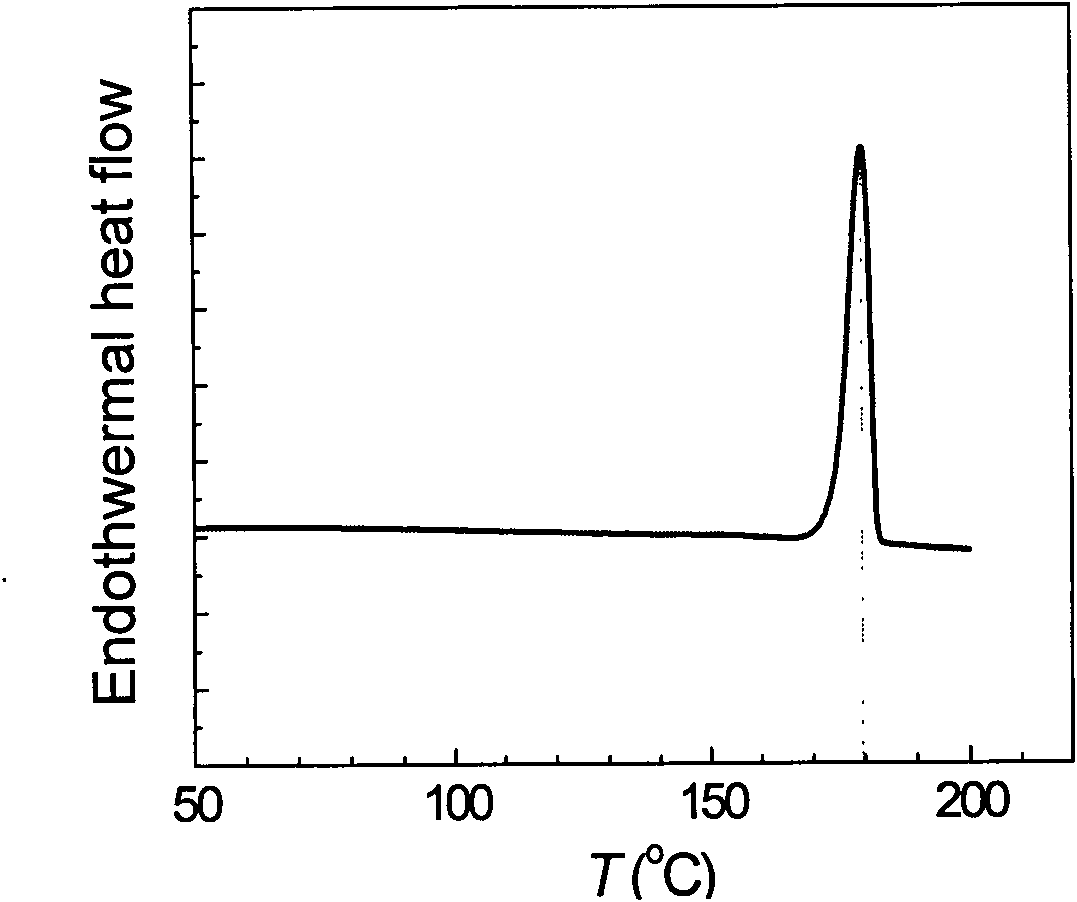

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com