Electric insulation material for lamellar detection element of gas sensor and preparation method thereof

A gas sensor, electrical insulating material technology, applied in electrical components, material analysis by electromagnetic means, insulators, etc., can solve problems such as large side effects and poor insulation effect, and achieve good mechanical properties, reduce defects, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of an electrical insulating material of the present invention and its sintering temperature test

[0020] Weigh 10.0 grams of analytically pure α-phase Al with a particle size of 50 nm 2 o 3 and 10.0 g of analytically pure alpha-phase Al with a particle size of 10 μm 2 o 3 , add 50 ml of alcohol, use α-phase Al 2 o 3 Ball milling for 30 hours, drying at 80°C to evaporate the alcohol, grinding in an agate mortar for half an hour, and then using uniaxial dry pressing method to press the powder into a strip green body under a pressure of 300MPa. The green body is subjected to thermal analysis test in an atmospheric air atmosphere.

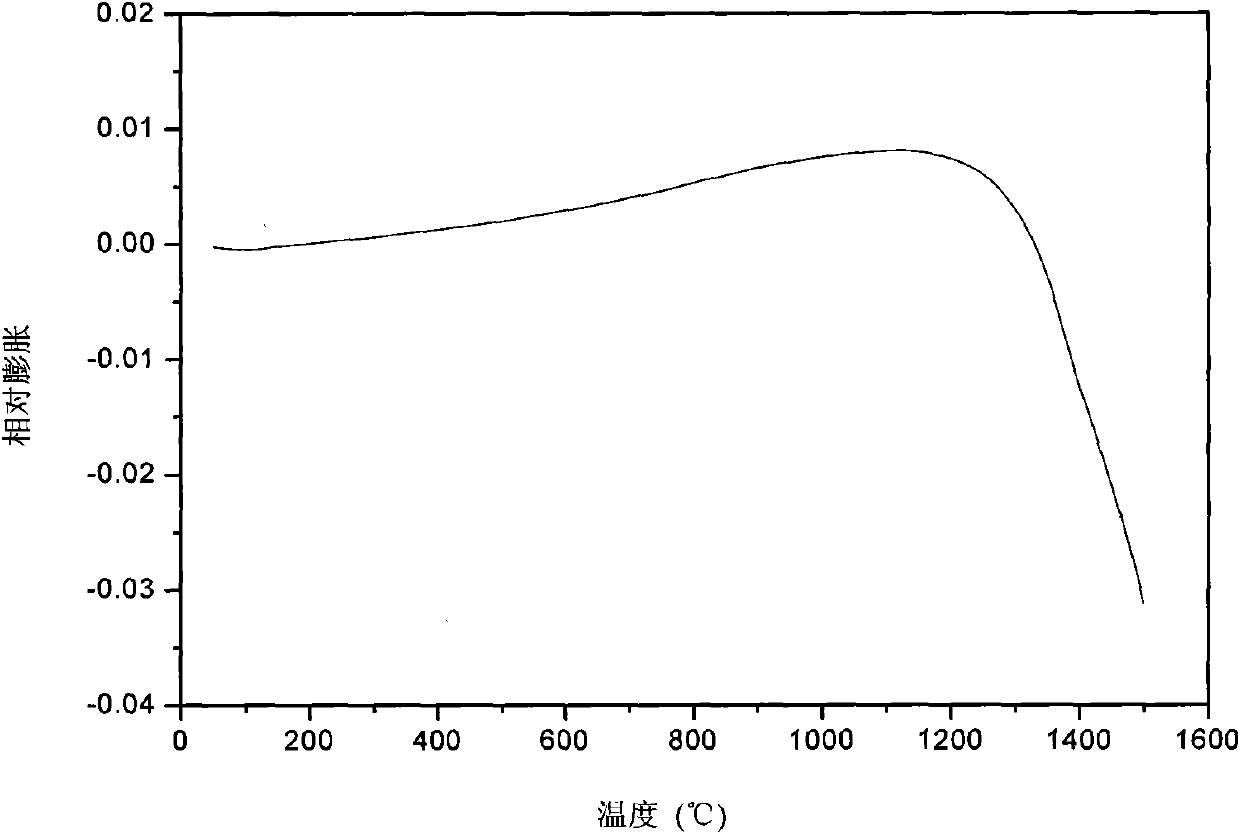

[0021] attached figure 1 The sintering shrinkage curves of the electrical insulating material samples prepared in this example in an air atmosphere at normal pressure are given. from figure 1It can be seen that the material starts sintering at 1200°C and reaches the maximum sintering rate at 1400°C, so the sinteri...

Embodiment 2

[0022] Embodiment 2: the test comparison of the sintering shrinkage rate of several electrical insulation materials of the present invention and existing electrical insulation materials

[0023] Table 1 below lists the sintering line shrinkage and the density of fired ceramics of ceramic green bodies with various components produced by casting method.

[0024] Table 1 Sintering line shrinkage and density of ceramic green bodies composed of several different materials

[0025]

[0026]

[0027] As can be seen from the data in the table, its sintering line shrinkage of several electrical insulating materials from numbering b to g of the present invention is similar to that of zirconia ZrO 2 The electrolyte material is very close, and there will be a good match with the electrolyte material during sintering, and the density of the fired ceramic body is relatively large. The ceramic green bodies numbered h and i are made of a single particle of 50 nanometers or 20 microns o...

Embodiment 3

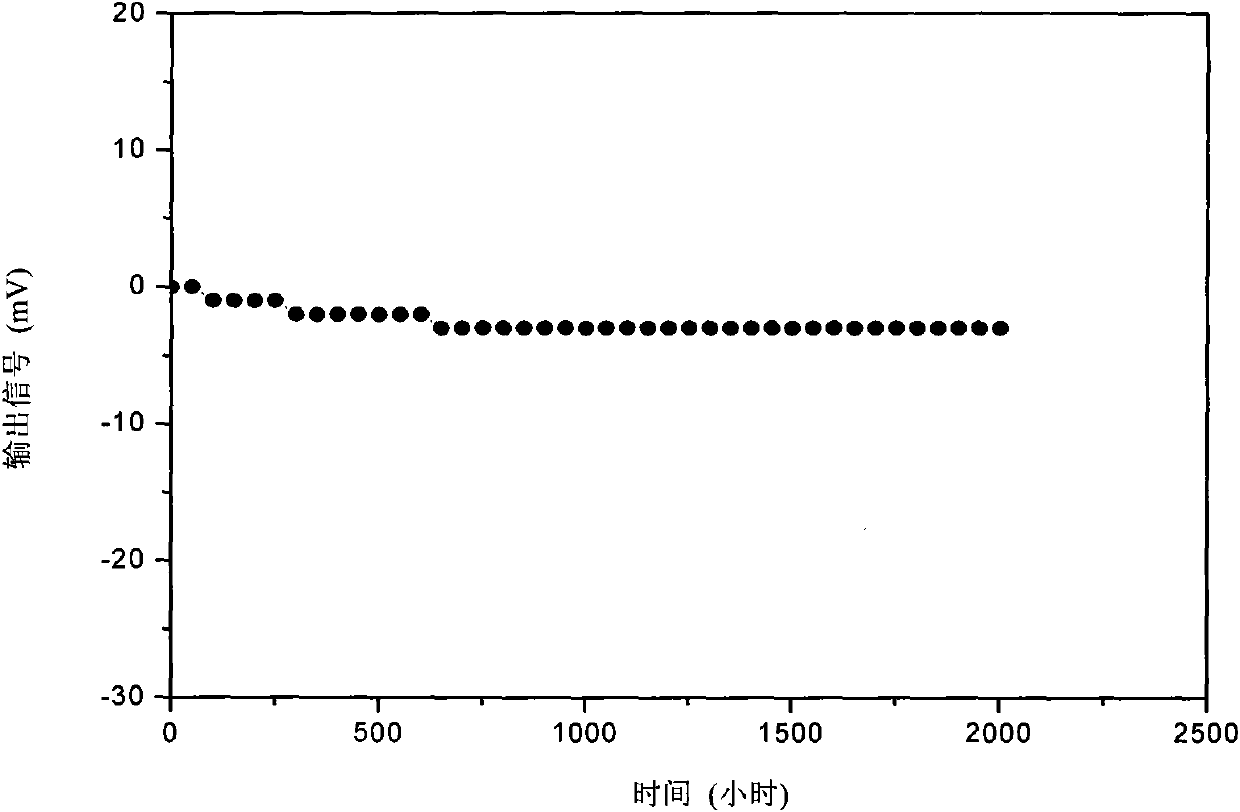

[0035] Embodiment 3: The application effect of the electrical insulation material of the present invention for a chip detection element of an oxygen sensor

[0036] In order to verify the performance of the electric insulating material of the present invention for the detection element of the gas sensor, in this embodiment, the material numbered c in the foregoing embodiment 2 is used to make the chip detection element of the oxygen sensor, and various performance tests are carried out .

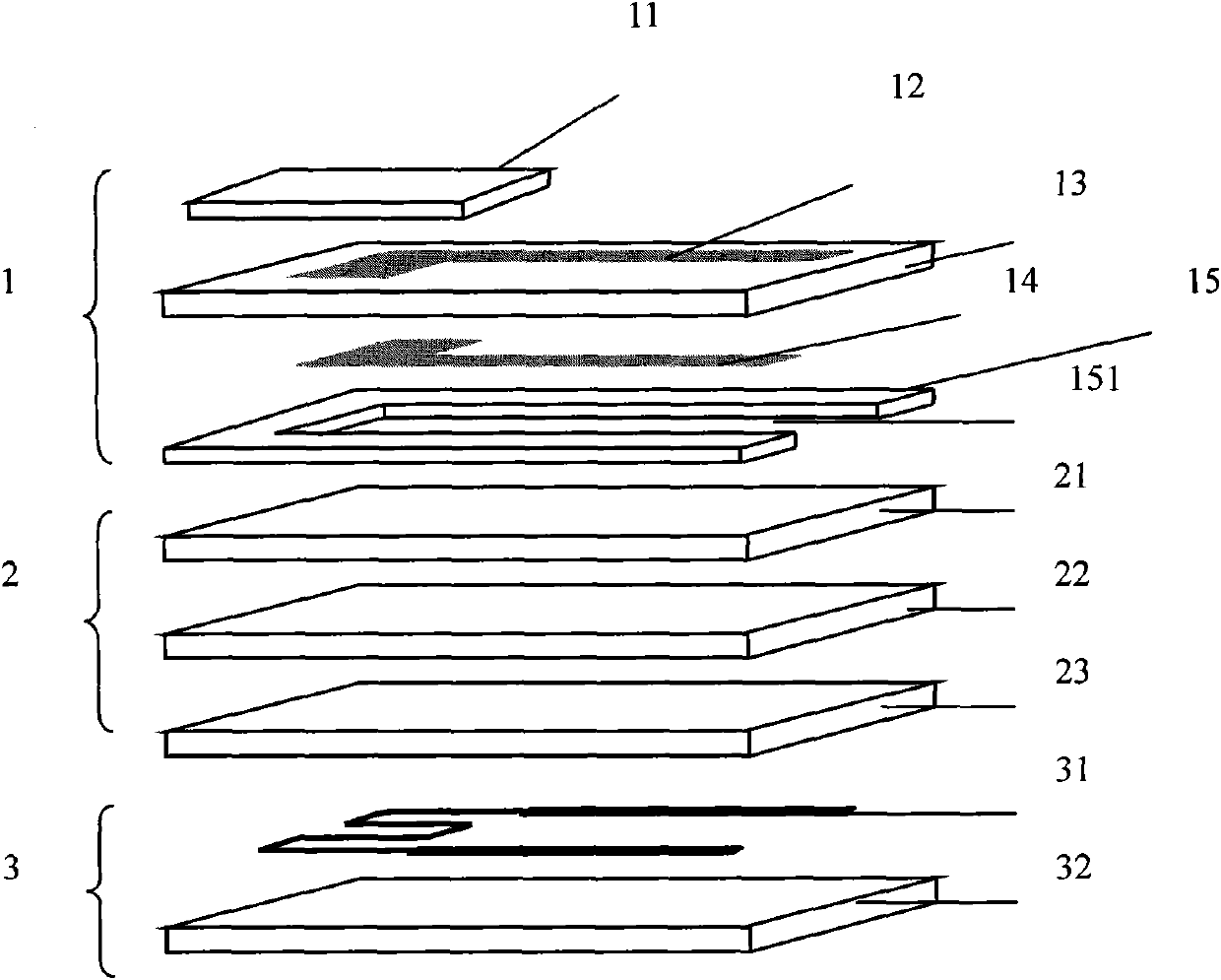

[0037] figure 2 It is a schematic diagram of the layered structure of a chip detection element of an oxygen sensor using an electrical insulating material of the present invention: the chip detection element includes a detection unit 1, an insulation unit 2 and a heating unit 3, and the insulation unit 2 is arranged between the detection unit 1 and the heating unit 3. Between the heating units 3 to play the role of electrical insulation; wherein the detection unit 1 is covered on the measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com