Method for preparing magneto-chromism ferroferric oxide sol

A ferroferric oxide and magnetotropic technology, applied in chemical instruments and methods, color-changing fluorescent materials, magnetic liquids, etc., to achieve the effects of good monodispersity, simple preparation method, and strong magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of Magnetochromic Iron Tetroxide Sol

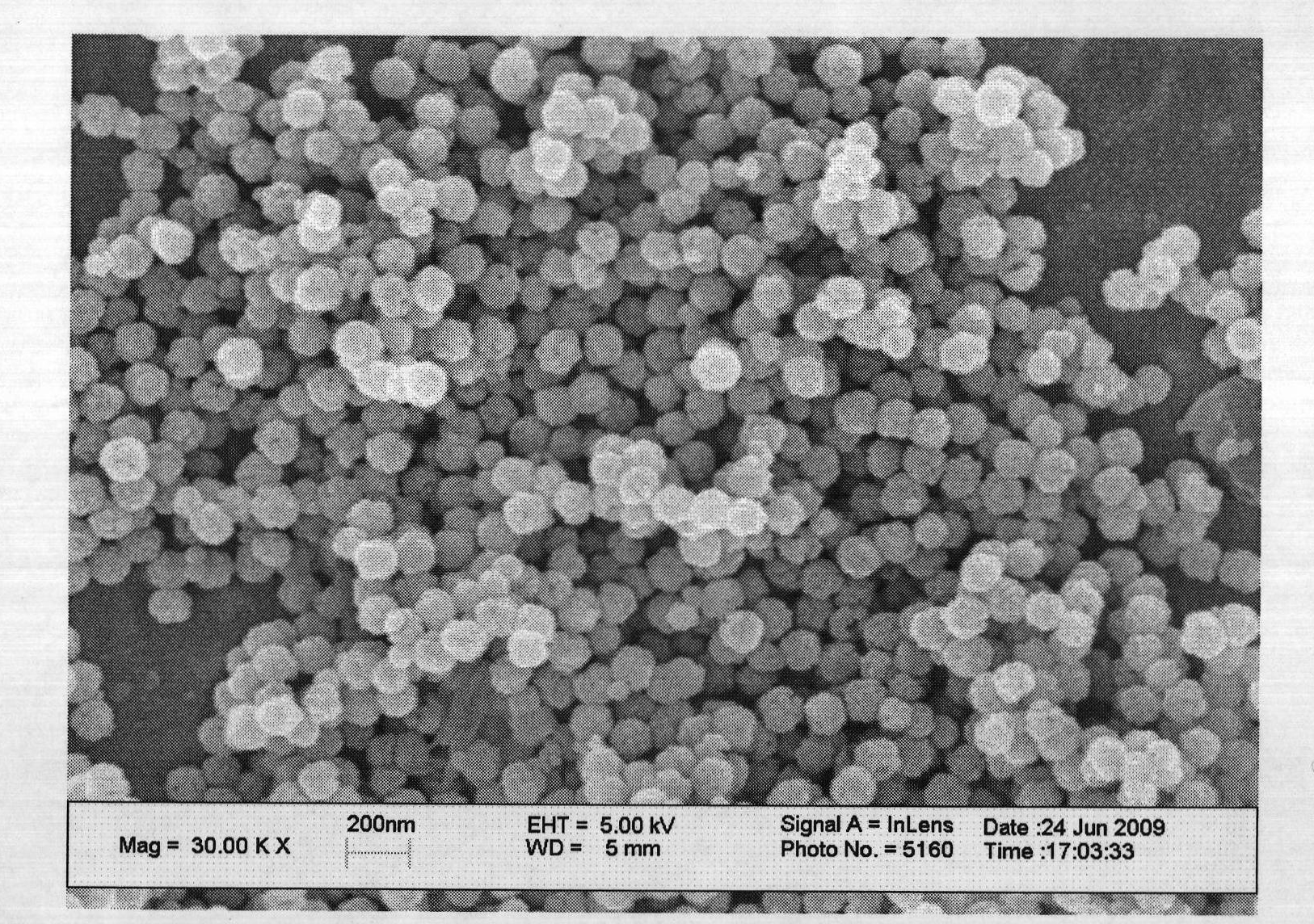

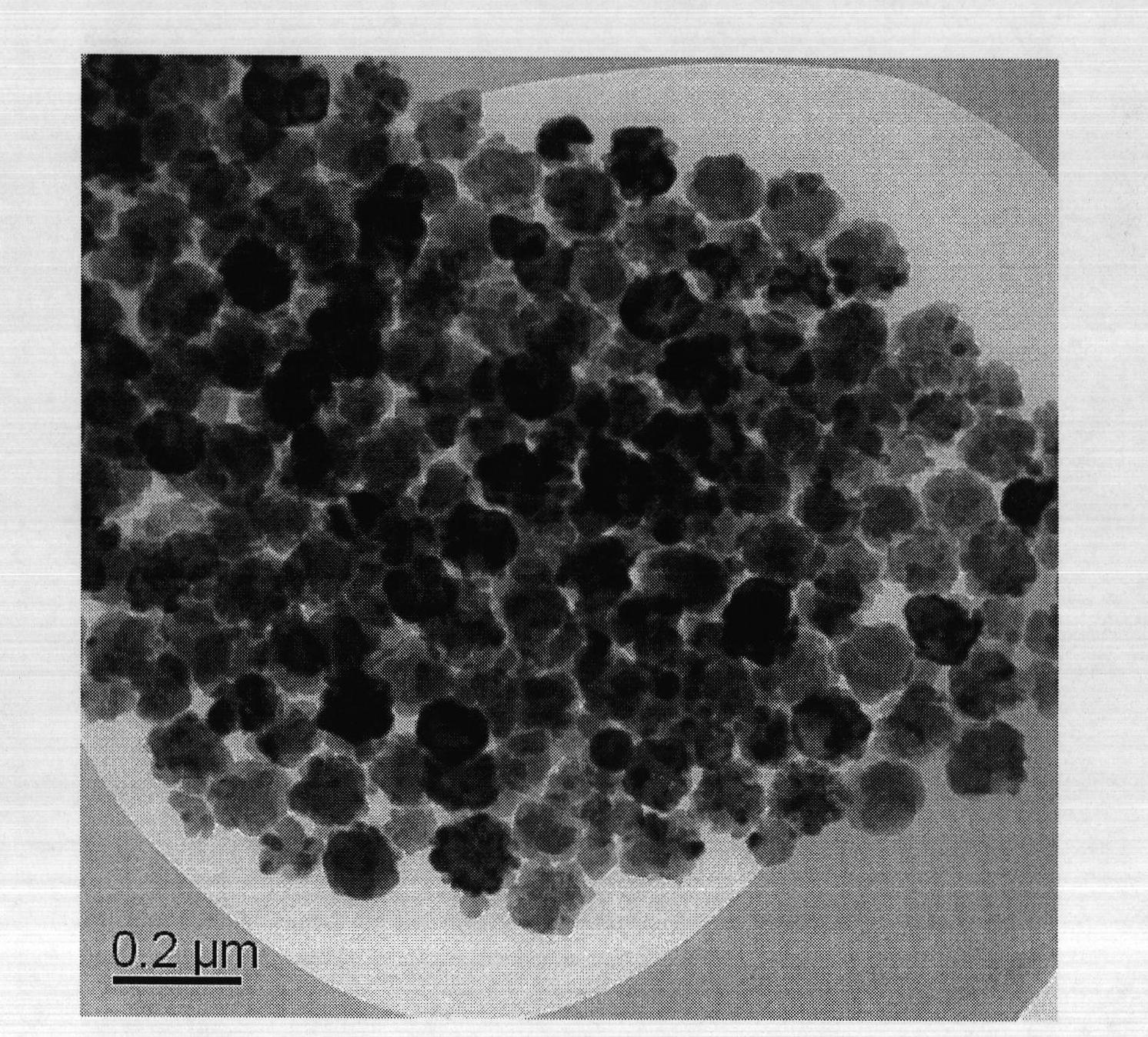

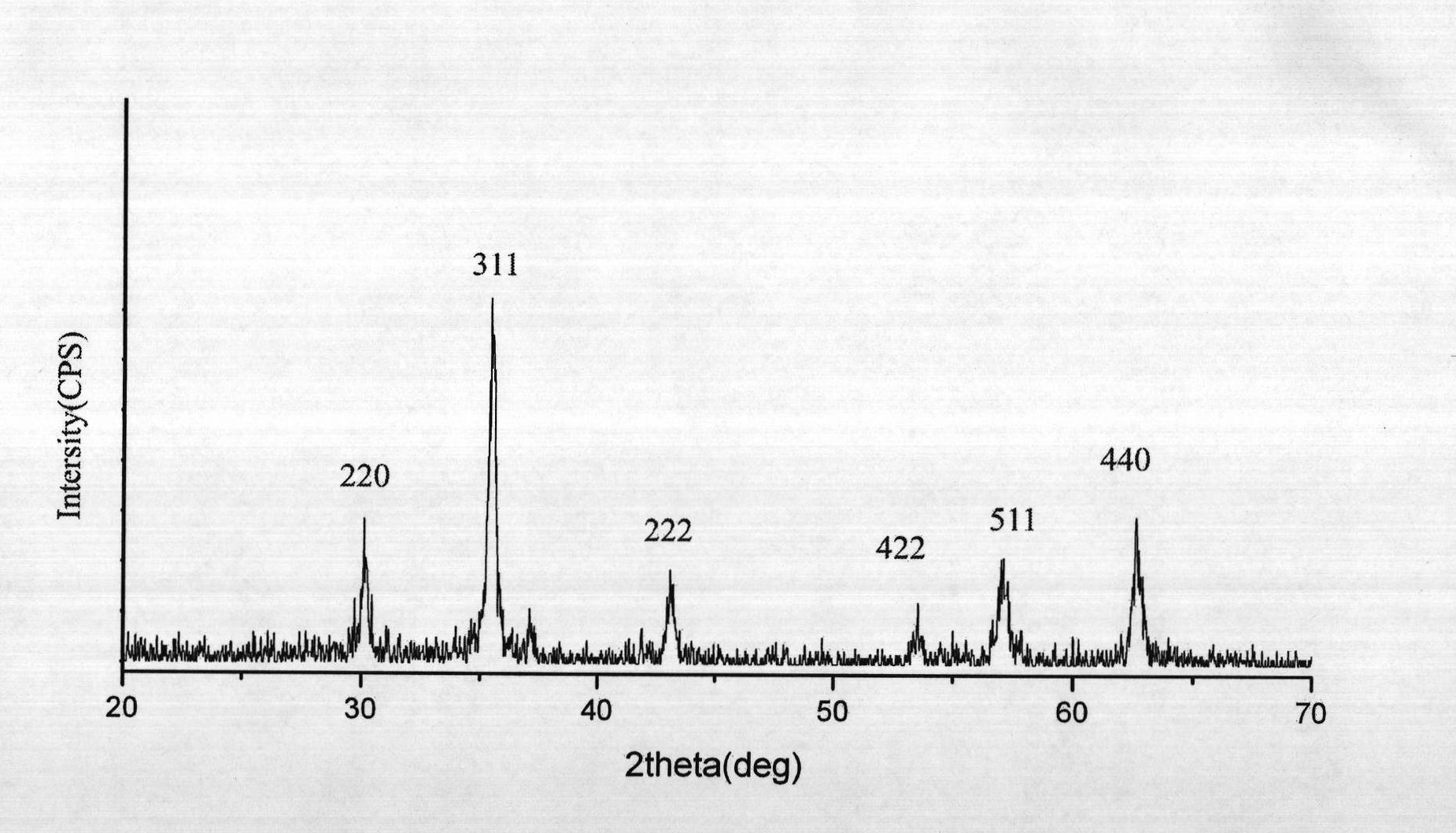

[0034] 1) Fe 3 O 4 Synthesis of Magnetic Particles

[0035] Mix ethylene glycol (EG) and diethylene glycol (DEG) according to the weight ratio of 13 / 7 to form 40ml of the required mixed solution; divide the mixed solution into two parts, and dissolve 3.80mmol hexahydrate trichlorohydrin in one part Ferric chloride and 1 g polyethylene glycol-20000 (A), dissolved 0.20 mmol ferrous chloride tetrahydrate (B) in one part. Add 3.6g of sodium acetate to liquid A under the action of ultrasound, stir well, then quickly add liquid B and stir quickly, transfer it to a hydrothermal kettle within 10 seconds, and seal it. The hydrothermal still that sample is housed is placed in blast oven, reacts at 220 degrees centigrade for 6 hours.

[0036] After the reaction, the hydrothermal kettle was cooled to room temperature. Pour the product in the liner into a small beaker, and collect the product by magnetic pr...

Embodiment 2

[0045] Example 2 Preparation of Magnetochromic Iron Tetroxide Sol

[0046] 1) Fe 3 O 4 Synthesis of Magnetic Particles

[0047] Mix ethylene glycol (EG) and diethylene glycol (DEG) according to the weight ratio of 27 / 13 to form 40 ml of the required mixed solution; divide the mixed solution into two parts, and dissolve 3.80 mmol hexahydrate trichlorohydrin in one part Ferric chloride and 1 g polyethylene glycol-20000 (A), dissolved 0.20 mmol ferrous chloride tetrahydrate (B) in one part. Add 3.6g of sodium acetate to liquid A under the action of ultrasound, stir well, then quickly add liquid B and stir quickly, transfer to a hydrothermal kettle, and seal. The hydrothermal still that sample is housed is placed in blast oven, reacts at 220 degrees centigrade for 6.5 hours.

[0048] After the reaction, the hydrothermal kettle was cooled to room temperature. Pour the product in the liner into a small beaker, and collect the product by magnetic precipitation using a...

Embodiment 3

[0053] 1) Synthesis of magnetic particles

[0054] Mix ethylene glycol (EG) and diethylene glycol (DEG) according to the weight ratio of 3 / 2 to make the required mixed solution 40ml; divide the mixed solution into two parts, and dissolve 3.80mmol hexahydrate trichlorohydrin in one part Ferric chloride, 1g polyethylene glycol-20000 and 3.6g sodium acetate (A), dissolved 0.20mmol ferrous chloride tetrahydrate (B) in one part. After mixing the two solutions evenly, transfer them to the Teflon lining of the hydrothermal kettle within 10 seconds, and seal them. The hydrothermal still that sample is housed is placed in blast oven, reacts at 220 degrees centigrade for 7.5 hours.

[0055] After the reaction, the hydrothermal kettle was cooled to room temperature. Pour the product in the liner into a small beaker, and collect the product by magnetic precipitation using a magnet. Then wash three times with ethanol, and then wash three times with distilled water before use.

[0056...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com