Zinc and zinc alloy plating black passivation solution and preparation method thereof

A technology of zinc alloy and passivation solution, which is applied in the coating process of metal materials, etc., can solve the problems of uneven passivation layer, easy peeling off, uneven black film, etc., achieve high market competitiveness, development potential, and easy operation Easy to learn, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

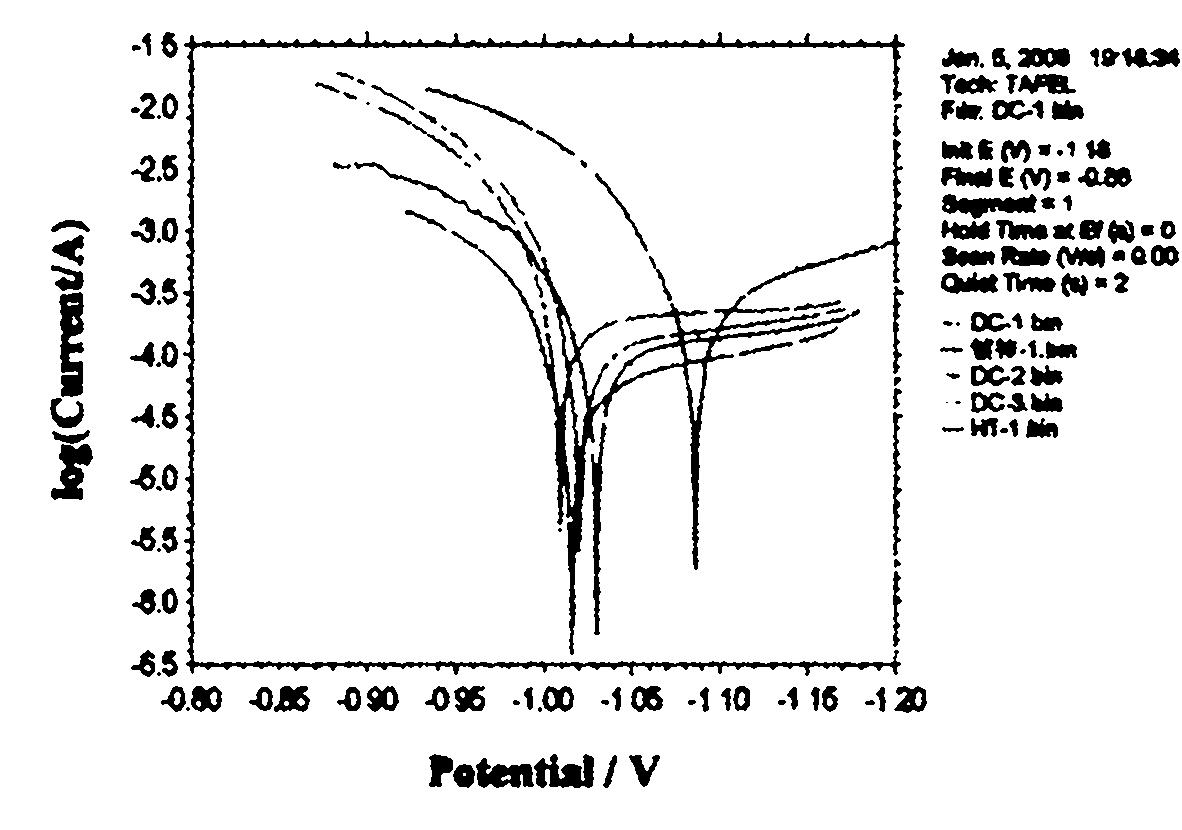

Image

Examples

Embodiment 1

[0046] Embodiment 1 (1L is example)

[0049] Silica sol 1g

[0050] Polyamide 1g

[0051] Anhydrous sodium sulfite 2g

[0052] Malonic acid 7g

[0053] Oxalic acid 7g

[0054] Sodium acetate 7g

[0057] Nitric acid 5g

[0058] the rest is water

[0059] Preparation method:

[0060] 1) Weigh 10g of trivalent chromium salt into the container, add 50ml of deionized water, stir evenly,

[0061] 2) Heat to 75-80°C, add 7g of malonic acid and 7g of oxalic acid, stir until completely dissolved;

[0062] 3) Add 2g of cobalt sulfate, 1g of silica sol and 1g of polyamide, stir to dissolve completely and mix evenly;

[0063] 4) Reduce to room temperature, add 2g of anhydrous sodium sulfite and 7g of sodium acetate, dissolve and stir evenly to obtain component A for later use;

[0064] 5) Take another container, add 50ml of deionized water, successively 3g of fe...

Embodiment 2

[0068] Chromium Sulfate Basic 12g

[0069] Cobalt sulfate 2g

[0070] Silane coupling agent A-171 1g

[0071] Potassium dihydrogen phosphate 2g

[0072] Sodium hypophosphite 3g

[0073] Succinic acid 7g

[0074] Glycine 10g

[0075] Acetic acid 3g

[0076] Nickel sulfate 5g

[0077] Silver nitrate 2g

[0079] Sulfuric acid 5g

[0080] the rest is water

[0081] Preparation method, method of use are identical with embodiment 1.

Embodiment 3

[0084] Cobalt sulfate 2g

[0085] Ethylenediaminetetramethylenephosphonic acid 2g

[0086] PVC 1g

[0087] Thiourea 4g

[0088] Glycolic acid 13g

[0089] Malic acid 4g

[0090] Oxalic acid 3g

[0091] Boric acid 5g

[0092] Manganese sulfate 2g

[0093] Silver nitrate 5g

[0095] Nitric acid 5g

[0096] the rest is water

[0097] The method of preparation and use is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com