Efficient scurf removing and itch relieving composite as well as preparation method and application thereof in shampoos

A technology for anti-dandruff, anti-itch, and shampoo, which is applied in the field of daily chemicals, can solve the problems of dry hair, covering shampoo pearls, lack of anti-dandruff effect, etc., to improve color stability, reduce sensitivity, and improve anti-dandruff. The effect of the crumb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

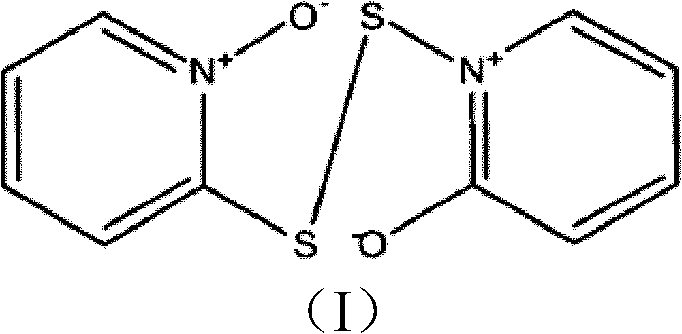

Method used

Image

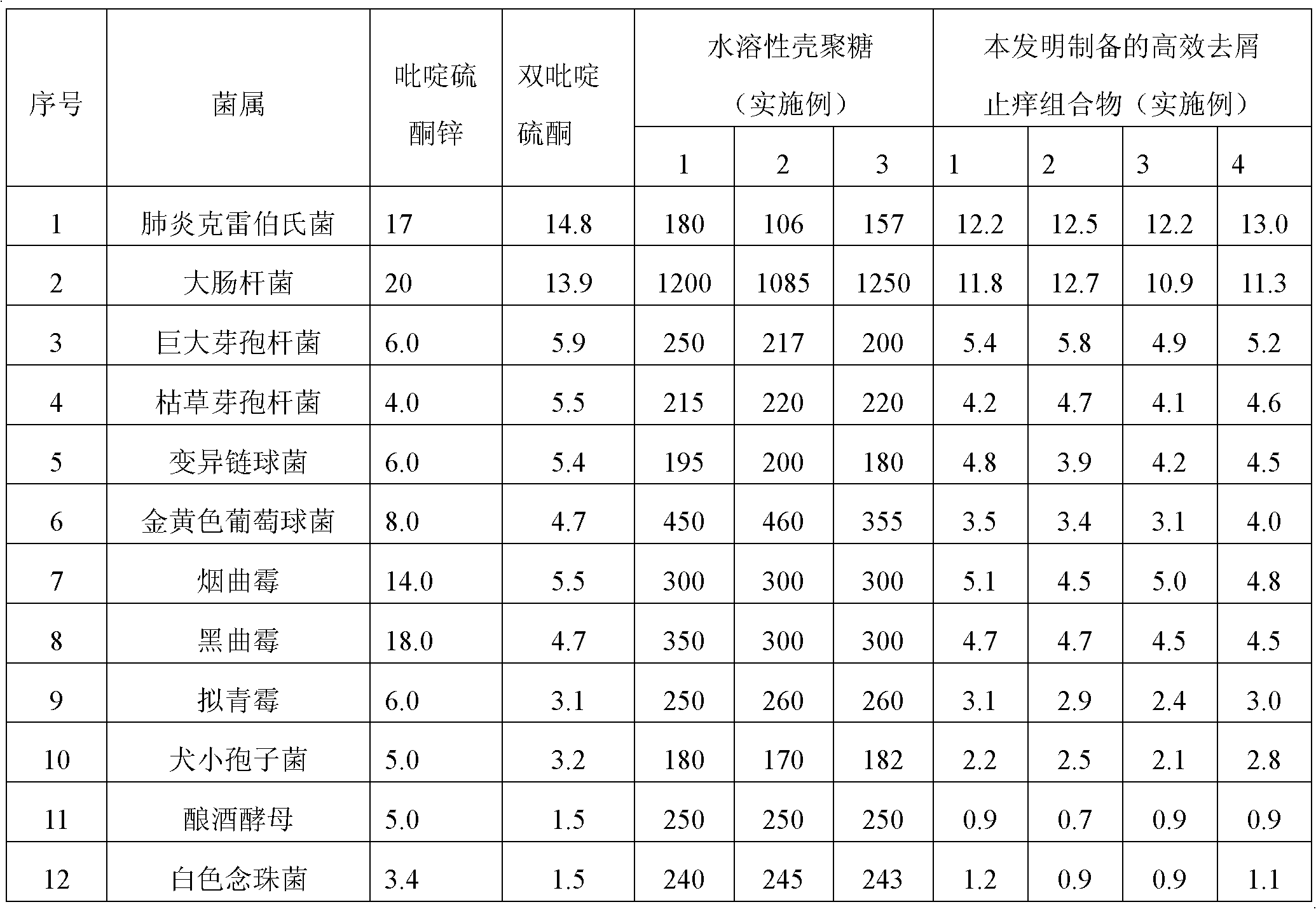

Examples

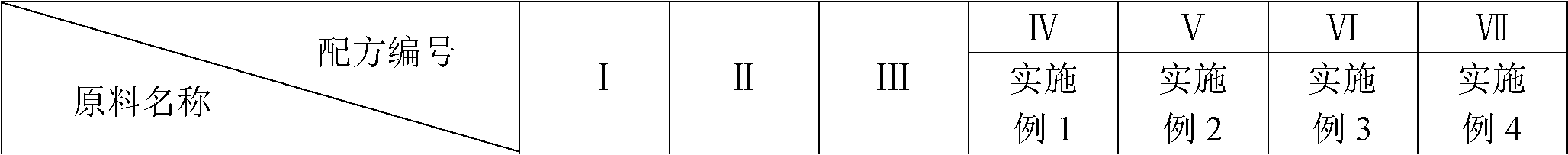

example 1

[0044] (1) Preparation of water-soluble chitosan derivatives: 3g chitosan was added in a 500ml there-necked flask, 300g distilled water was added, stirred; 1.5g glacial acetic acid was slowly added dropwise to dissolve the chitosan; then 10g acrylic acid and 5g propylene were added Amide, add 0.03g ammonium persulfate initiator, nitrogen protection, heat up to 55°C; stir and react at constant temperature for 5.0h, cool down to obtain chitosan / acrylic acid / acrylamide polymer aqueous solution. Add 100ml of absolute ethanol to the obtained polymer aqueous solution, let it stand for 3 hours to precipitate the polymer, filter it with suction, wash the obtained solid three times with absolute ethanol, and freeze-dry to obtain chitosan / acrylic acid / acrylamide polymer .

[0045] (2) Preparation of high-efficiency anti-dandruff and antipruritic composition: 50 g of bispyridinethione (commercially available, cosmetic grade, the same below) with a mass percentage of 99.9% and a particle ...

Embodiment 2

[0047](1) Preparation of water-soluble chitosan derivatives: 10g chitosan is added in a 500ml there-necked flask, 300g distilled water is added, stirred; 5.0g glacial acetic acid is slowly added dropwise to dissolve the chitosan; 10g acrylic acid and 12g 2- Acrylamido-2-methylpropanesulfonic acid, nitrogen protection, heating up to 85°C, adding 0.25g of initiator azobisisobutyronitrile, stirring at constant temperature for 10h, cooling down to obtain chitosan / acrylic acid / 2-propylene Amino-2-methylpropanesulfonic acid polymer aqueous solution; the obtained polymer aqueous solution was added to 100ml of absolute ethanol, and stood for 8h to precipitate the polymer, suction filtered, and the obtained solid was repeatedly washed three times with absolute ethanol, Freeze drying to obtain chitosan / acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid polymer;

[0048] (2) Preparation of high-efficiency anti-dandruff antipruritic composition: 40 g of bispyridinethione with a partic...

Embodiment 3

[0050] (1) Preparation of water-soluble chitosan derivatives: 5g chitosan was added in a 500ml there-necked flask, 300g distilled water was added, stirred; 3.0g glacial acetic acid was slowly added dropwise to dissolve the chitosan; 10g acrylic acid and 15g dimethylformamide were added Diallyl ammonium chloride, under nitrogen protection, heated up to 75°C, added 0.1g of initiator potassium persulfate, stirred at constant temperature for 7 hours, cooled to obtain chitosan / acrylic acid / dimethyldiallyl chloride Ammonium polymer aqueous solution; add 100ml of absolute ethanol to the obtained polymer aqueous solution, let it stand for 5 hours to precipitate the polymer, filter it with suction, wash the obtained solid three times with absolute ethanol, and freeze-dry to obtain chitosan / acrylic acid / Dimethyldiallylammonium Chloride Polymer.

[0051] (2) Preparation of high-efficiency anti-dandruff antipruritic composition: 50 g of bispyridinethione with a mass percentage of 90.0% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com