Low-silver electro vacuum brazing filler metal used for sealing weld of electronic device

An electronic device, silver-electric technology, applied in the field of low-silver-electric vacuum solder, can solve the problems of melting point, atomic radius, solid solubility and crystal structure difference, increased brazing temperature, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The chemical composition is by mass percentage: 41% Ag, 52.85% Cu, 4% Sn, 2% In and 0.15% Ni.

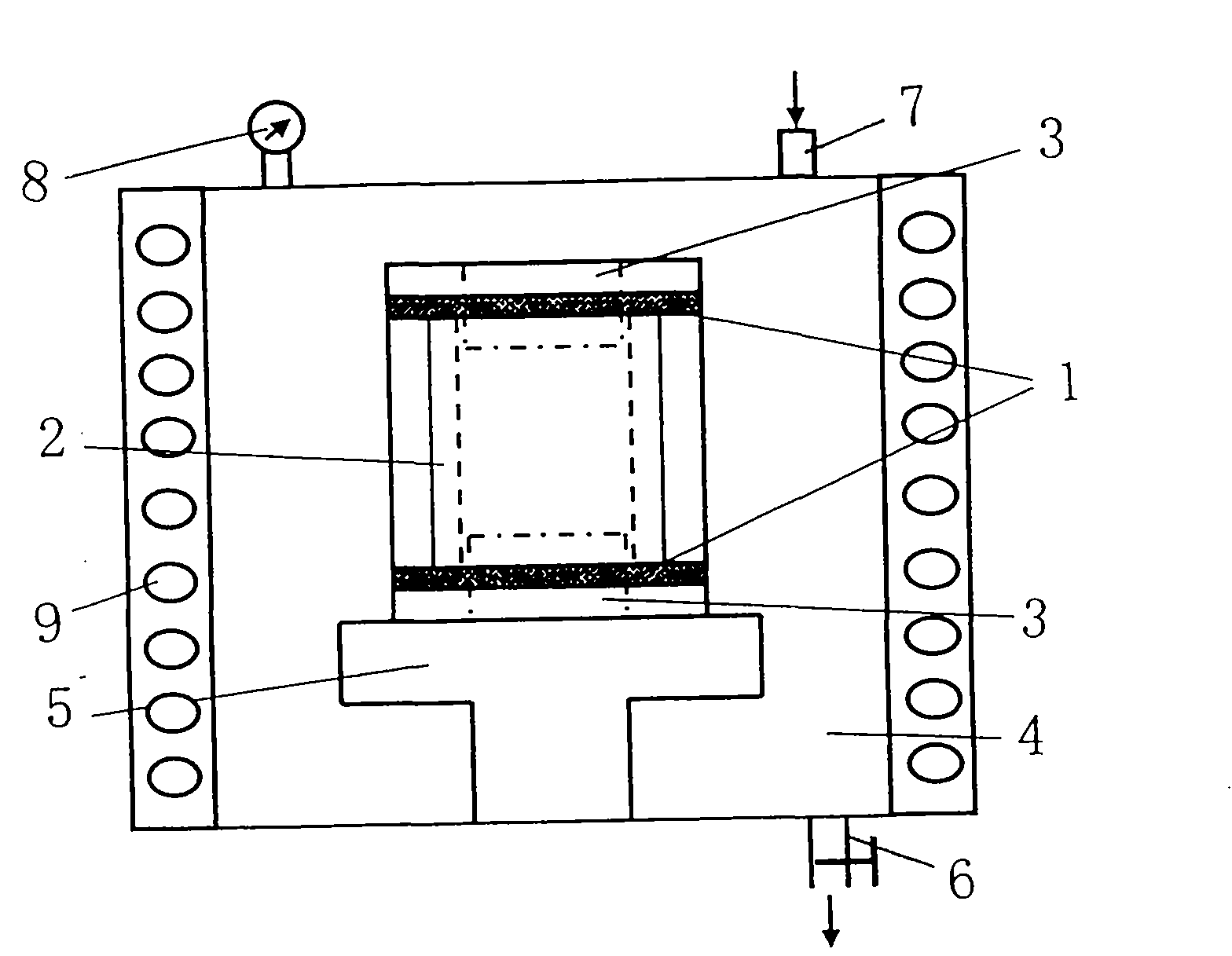

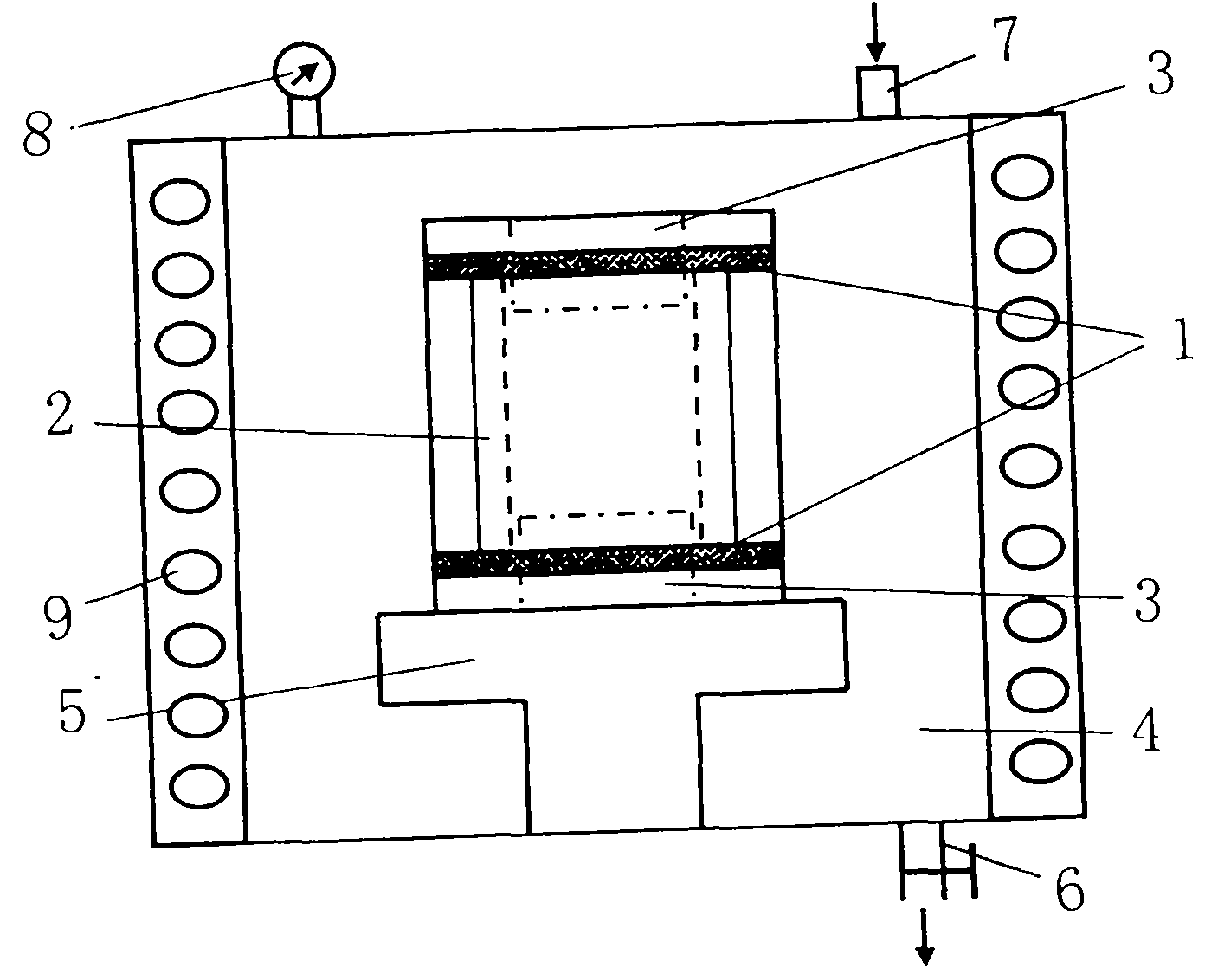

[0026] The solidus temperature of the low-silver electric vacuum solder (foil) used for sealing and soldering of electronic devices obtained from the above-mentioned composition ratio is about 30 μm to 50 μm, the solidus temperature is 690 ° C, the liquidus line is 766 ° C, and the temperature interval is 32 ℃. The gas discharge secondary tube is sealed and welded by using the low-silver electric vacuum brazing filler metal foil. The welding method is: see figure 1 , the foil material 1 is clamped between the ceramic tube 2 to be welded and the Kovar sheet 3, assembled into a lap joint and then placed in a vacuum brazing machine with a vacuum port 6, an air inlet 7 and a vacuum gauge 8 On the stage 5 in the furnace 4, the furnace cover is closed again. like figure 1 shown, by vacuuming the vacuum port 6 to 10 -3 After Pa, reverse charge A through air inlet 7 r Gas to 5 ...

Embodiment 2

[0028] The chemical composition is by mass percentage: 41.5% of Ag, 52.4% of Cu, 4.5% of Sn, 1.5% of In and 0.10% of Ni.

[0029] The low-silver electric vacuum brazing material (foil material) used for sealing and soldering of electronic devices obtained from the above-mentioned composition ratio with a thickness of about 35 μm to 50 μm. The solidus temperature is 692°C, the liquidus is 765°C, and the temperature interval is 32°C. The low-silver electric vacuum alloy solder foil is used to seal and weld electric vacuum devices (gas discharge diodes). The welding method is: see figure 1 Firstly, the foil material 1 is sandwiched between the ceramic tube 2 to be welded and the Kovar sheet 3, assembled into a lap joint and then placed in a vacuum brazing machine with a vacuum port 6, an air inlet 7 and a vacuum gauge 8 On the stage 5 in the furnace 4, the furnace cover is closed again. like figure 1 shown, by vacuuming the vacuum port 6 to 10 -3 After Pa, reverse charge A thr...

Embodiment 3

[0031] The chemical composition is by mass percentage: 42% Ag, 51.8% Cu, 4% Sn, 2% In and 0.2% Ni.

[0032] The solidus temperature of the low-silver electric vacuum solder (foil) used for sealing and soldering of electronic devices obtained from the above-mentioned composition ratio is about 34 μm to 50 μm, the solidus temperature is 693°C, the liquidus line is 762°C, and the temperature interval is 90°C. ℃. The low-silver electric vacuum alloy solder foil is used to seal and weld electric vacuum devices (gas discharge diodes). please see figure 1 , the welding method is: first clamp the foil material 1 between the ceramic tube 2 to be welded and the Kovar alloy sheet 3, assemble it into a lap joint and place it with a vacuum port 6, an air inlet 7 and a vacuum gauge 8 On the stage 5 in the vacuum brazing furnace 4 of the vacuum brazing furnace 4, close the furnace cover again. like figure 1 As shown, vacuum the vacuum port 6 to 10 -3 After Pa, reverse charge A through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com