Method for synthesizing zinc sulfide quantum dots by using oil amine

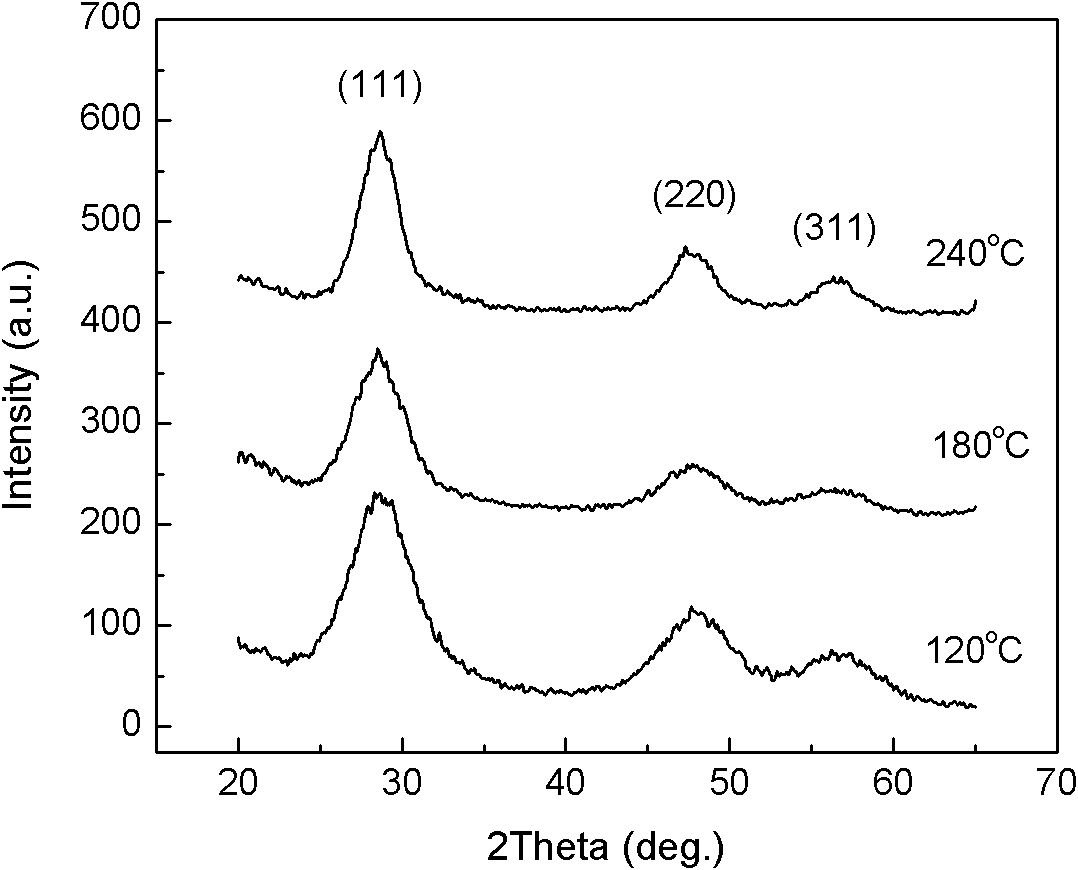

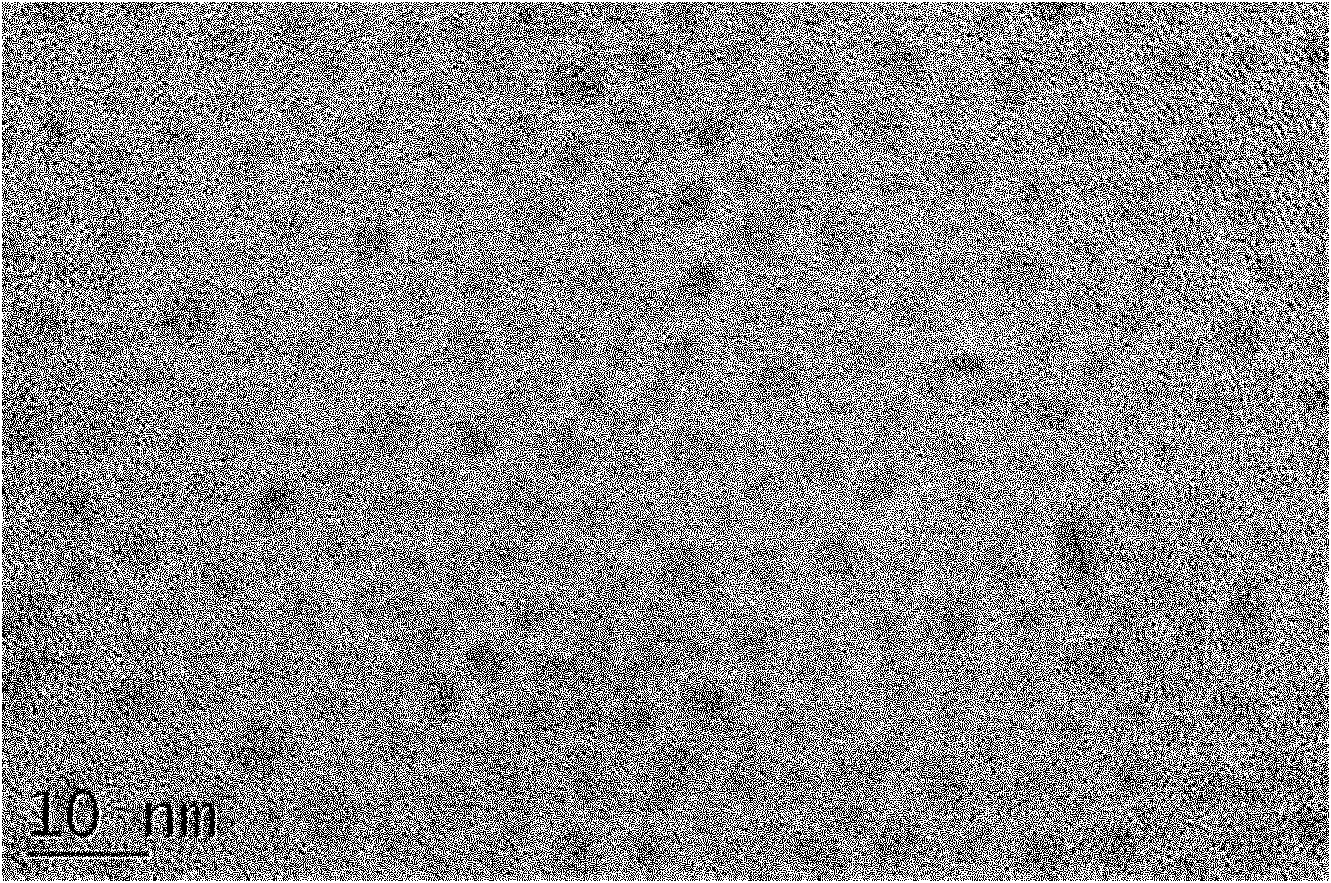

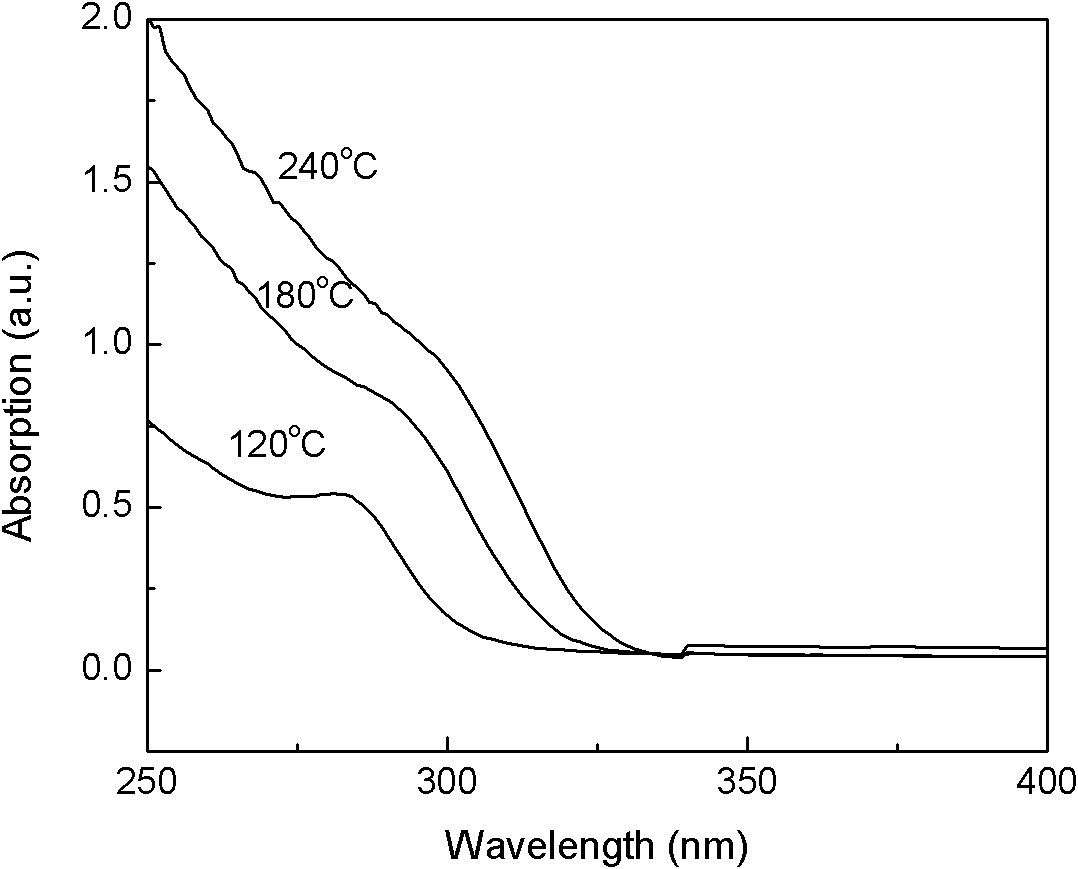

A quantum dot and zinc sulfide technology, which is applied in the field of zinc sulfide quantum dot synthesis with oleylamine, can solve problems such as easy agglomeration, difficulty in preparing uniform quantum dots with small size, and harsh reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) First, mix 0.5 mmol of zinc nitrate dihydrate and 5 ml of oleylamine, then heat the mixed solution to 60° C. for 100 minutes, and pass in argon gas while vigorously stirring to obtain a mixed solution A;

[0021] 2) Next, add 0.5 mmol of sulfur powder to the mixed solution A and heat it to 60°C. During the whole process, argon gas is passed into it while vigorously stirring, and the solution B is obtained after reacting for 120 minutes;

[0022] 3) Then, add 10 ml of ethanol to solution B and centrifuge at a speed of 4000 rpm for 10 minutes, remove the supernatant to obtain a precipitate;

[0023] 4) Add 5 milliliters of chloroform and 10 milliliters of ethanol to the precipitate and ultrasonically dissolve the precipitate, mix the solution evenly, centrifuge at a speed of 4000 rpm for 10 minutes, remove the supernatant to obtain a precipitate, then add 5 milliliters of chloroform and 10 ml of ethanol and sonication to dissolve the precipitate completely, mix the sol...

Embodiment 2

[0026] 1) First, mix 1 mmol of zinc nitrate dihydrate and 7 ml of oleylamine, then heat the mixed solution to 80° C. for 120 minutes, and pass in argon gas while vigorously stirring to obtain mixed solution A;

[0027] 2) Next, add 1 mmol of sulfur powder to the mixed solution A and heat it to 90°C. During the whole process, argon gas is introduced, and at the same time, it is vigorously stirred, and the solution B is obtained after reacting for 100 minutes;

[0028] 3) Then, add 12 milliliters of ethanol to solution B and centrifuge at a speed of 5000 rpm for 8 minutes, remove the supernatant to obtain a precipitate;

[0029] 4) Add 6 milliliters of n-hexane and 12 milliliters of ethanol to the precipitate and ultrasonically dissolve the precipitate, mix the solution evenly, centrifuge at a speed of 5000 rpm for 8 minutes, remove the supernatant to obtain a precipitate, then add 6 milliliters of n-hexane to the precipitate Alkanes and 12 milliliters of ethanol and ultrasound ...

Embodiment 3

[0032] 1) First, mix 1.5 millimoles of zinc nitrate dihydrate and 9 ml of oleylamine, then heat the mixed solution to 90° C. for 80 minutes, and pass in argon gas while vigorously stirring to obtain mixed solution A;

[0033] 2) Next, add 1.5 millimoles of sulfur powder to the mixed solution A and heat it to 120°C. During the whole process, argon gas is introduced, while stirring vigorously, and reacted for 80 minutes to obtain solution B;

[0034] 3) Then, add 14 milliliters of ethanol to solution B and centrifuge at a speed of 6000 rpm for 6 minutes, remove the supernatant to obtain a precipitate;

[0035] 4) Add 7 milliliters of tetrachlorethylene and 14 milliliters of ethanol to the precipitate and ultrasonically dissolve the precipitate, mix the solution evenly, centrifuge at a speed of 6000 rpm for 6 minutes, remove the supernatant to obtain a precipitate, and then add 7 milliliters to the precipitate Tetrachlorethylene and 14 milliliters of ethanol are ultrasonically di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com