Preparation method of porous antireflection film formed by nanopolymer hollow particles

一种纳米聚合物、防反射的技术,应用在纳米技术、纳米技术、纳米光学等方向,能够解决机械性能差、制备工艺复杂等问题,达到成本低、制备工艺简单、好机械强度和耐摩擦性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

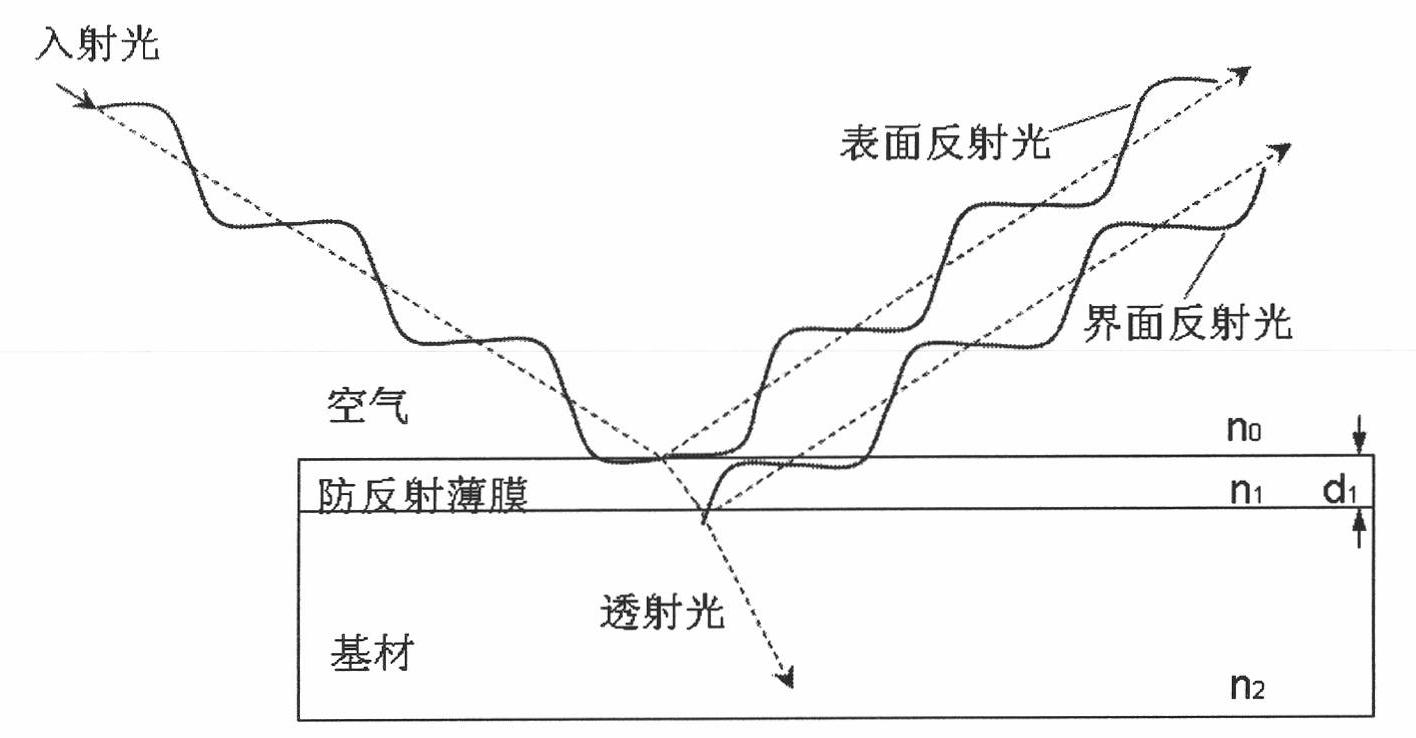

[0032]The steps of the preparation method of the porous anti-reflection film composed of nanometer polymer hollow particles are as follows:

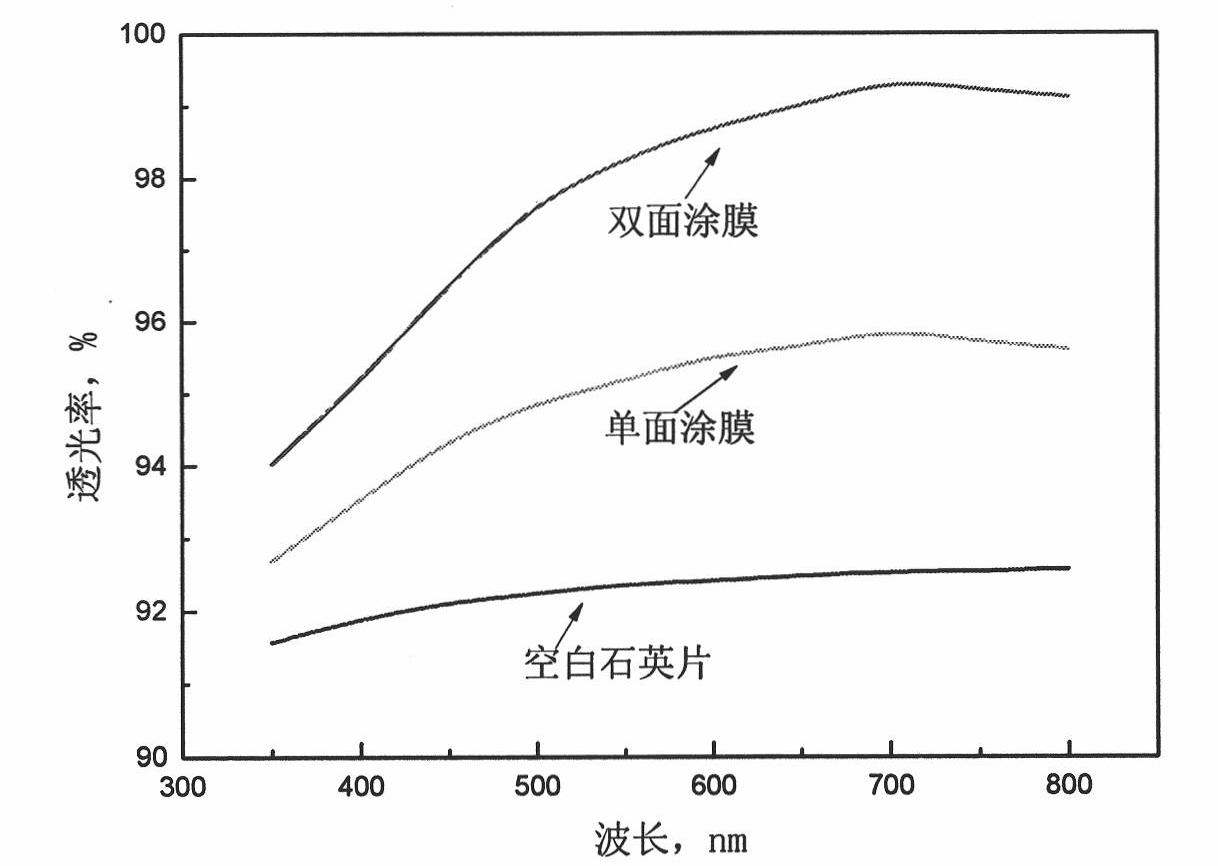

[0033] 1) Prepare the nano-polymer capsules into an aqueous dispersion with a mass percent concentration of 3-7%, spin-coat the surface of the substrate on one or both sides through a homogenizer, and form nano-polymer capsules after the water evaporates film;

[0034] 2) Place the film containing nanopolymer capsules in a vacuum oven and dry at 150 to 180°C for 4 to 5 hours. After the water in the film and the core material in the nanopolymer capsules are completely volatilized, the nanopolymer The capsules are transformed into nano-polymer hollow particles, and a porous anti-reflection film composed of nano-polymer hollow particles is obtained. The thickness of the porous anti-reflection film is 74-127nm, the refractive index is 1.15-1.26, and the porosity is 0.47-0.66.

[0035] The substrates are transparent quartz sheets and glass ...

Embodiment 1

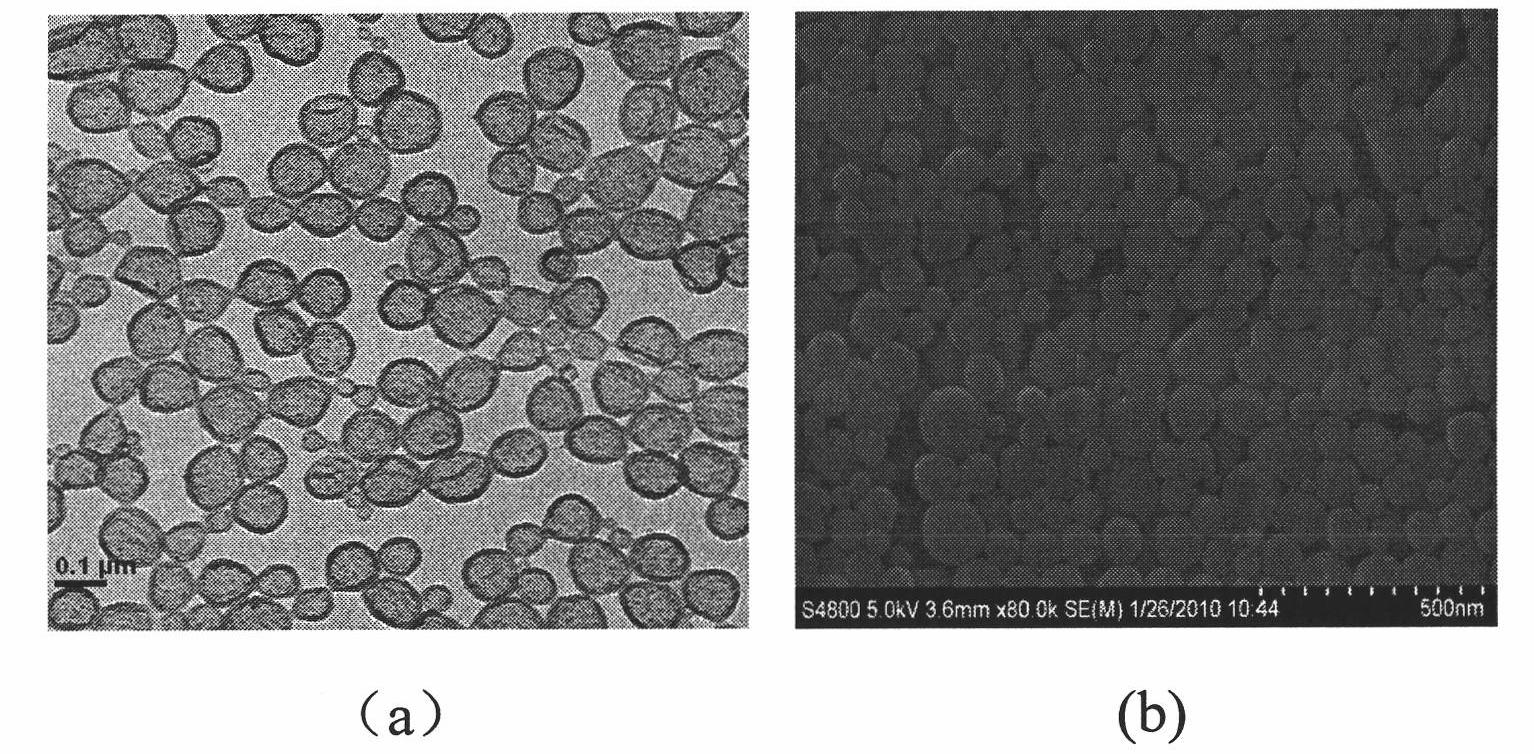

[0044] (1) Preparation of nanopolymer capsules:

[0045] 1) Mix 7 grams of methacrylic acid, 6 grams of methyl methacrylate, 0.3 grams of 4,4-azo-bis(4-cyanovaleric acid) and 2 grams of dodecyl-3-carbonitrile Trithiopentylvaleric acid was dissolved in 50 grams of dioxane solvent, and polymerized at 70° C. for 9 hours to obtain an amphiphilic macromolecular reversible addition scission chain transfer reagent. The structural formula is as follows:

[0046] 2) 0.5 gram of the above-mentioned amphiphilic macromolecular reversible addition chain scission chain transfer reagent and 70 gram of deionized water are formulated into an aqueous solution as the water phase, and 6 gram of methyl methacrylate, 8 gram of p-vinylbenzene, The oil phase composed of 0.05 g of azobisisobutyronitrile and 7 g of paraffin was uniformly mixed, and a fine emulsion was prepared by an ultrasonic pulverizer under the action of a high shear field.

[0047] 3) Move the mini-emulsion to the reactor, reac...

Embodiment 2~5

[0057] Examples 2-5 are the same as Example 1 except that the concentrations of the aqueous dispersions of nanocapsules are different. The mass percent concentrations of the aqueous dispersions of nanocapsules used in Examples 2 to 5 were 3%, 4%, 5% and 7%, respectively, and the specific property parameters of the prepared porous antireflection films are shown in Table 2. It can be found from Table 2 that with the increase of the concentration of the aqueous dispersion of nanocapsules, the thickness and the refractive index of the prepared anti-reflection film all increase thereupon, this is because when the concentration of the aqueous dispersion of nanocapsules increases, at the same Under the spin coating speed, the number of nanocapsules in the formed film increases and the arrangement is more compact, so the thickness of the film layer increases, and the porosity of the porous film decreases after vacuum drying, so that the refractive index of the film increases accordingl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com