Method for eliminating glucose inhibition effect of clostridium acetobutylicum

A technology for Clostridium acetobutylicum and glucose inhibition, which is applied in the field of genetic engineering to achieve the effect of increasing the concentration of ABE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 , Construction of pSY6-ccpA plasmid vector

[0052] Amplify the ccpA targetron fragment by PCR, then use XhoI and BsrG I to perform double digestion, and connect it to the pSY6 vector that has also been digested by XhoI and BsrG I to obtain the interrupted plasmid pSY6-ccpA, wherein the template for PCR amplification of ccpA targetron And the primer design method comes from the Targetron of Sigma-Aldrich company TM Gene Knockout System (TA0100) Kit, the specific steps are as follows:

[0053] 1.1. Primer design

[0054] ReferenceTargetron TM The method that Gene Knockout System (TA0100) Kit provides, respectively designs primer ccpA-IBS (as shown in sequence SEQ ID NO.: 1), ccpA-EBS1d (as shown in sequence SEQ ID NO.: 2) and ccpA-EBS2 ( The sequence shown as SEQ ID NO.: 3) was used to construct the pSY6-ccpA plasmid vector.

[0055] EBS universal required for PCR amplification by Targetron TM Gene Knockout System (TA0100) Kit comes with it.

[0056]...

Embodiment 2

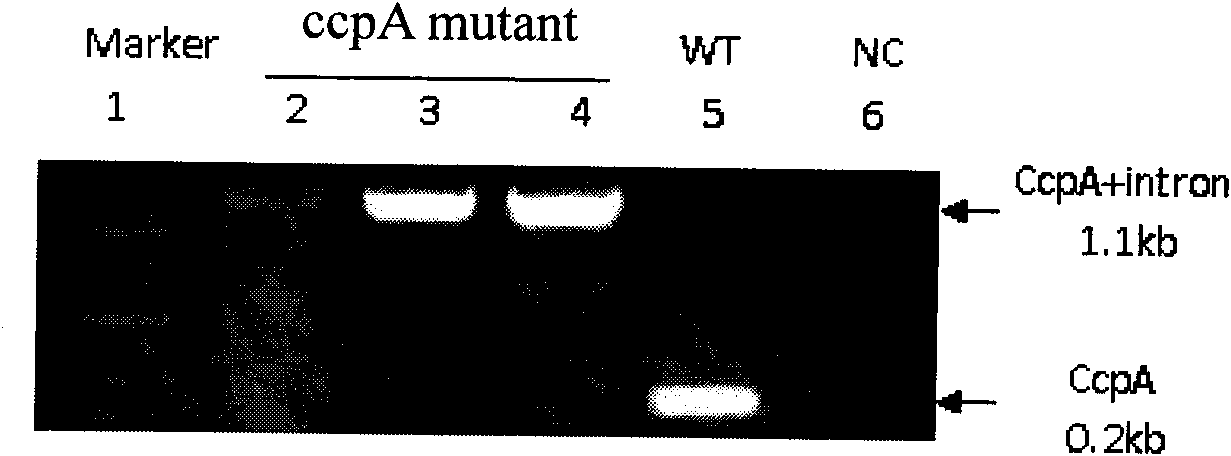

[0065] Example 2 , Clostridium acetobutylicum ccpA-mutant strain construction and detection

[0066]After the pSY6-ccpA plasmid was methylated at the Cac8I site by E.coli ER2275 / pANS1, it was electroporated into Clostridium acetobutylicum ATCC 824. After recovery overnight, 200 μl of the cell solution was spread on a CGM plate supplemented with 40 μg / mL erythromycin , after culturing in an anaerobic box at 37°C for 48-96 hours, pick a single bacterium for colony PCR verification, the specific process is as follows:

[0067] 2.1. Methylation of pSY6-ccpA plasmid

[0068] To prevent exogenous DNA from being cut and degraded by its restriction system after entering c.acetobutylicum, the pSY6-ccpA plasmid needs to be methylated (Mermelstein, L.D and Papoutsakis, E.T.Appl Environ Microbiol.vol59.issue 4.page 1077-81).

[0069] The pANS1 plasmid was treated with CaCl 2 Transform into E.coli ER2275 by heat shock method to obtain strain E.coliER2275 / pANS1.

[0070] Transform the ...

Embodiment 3

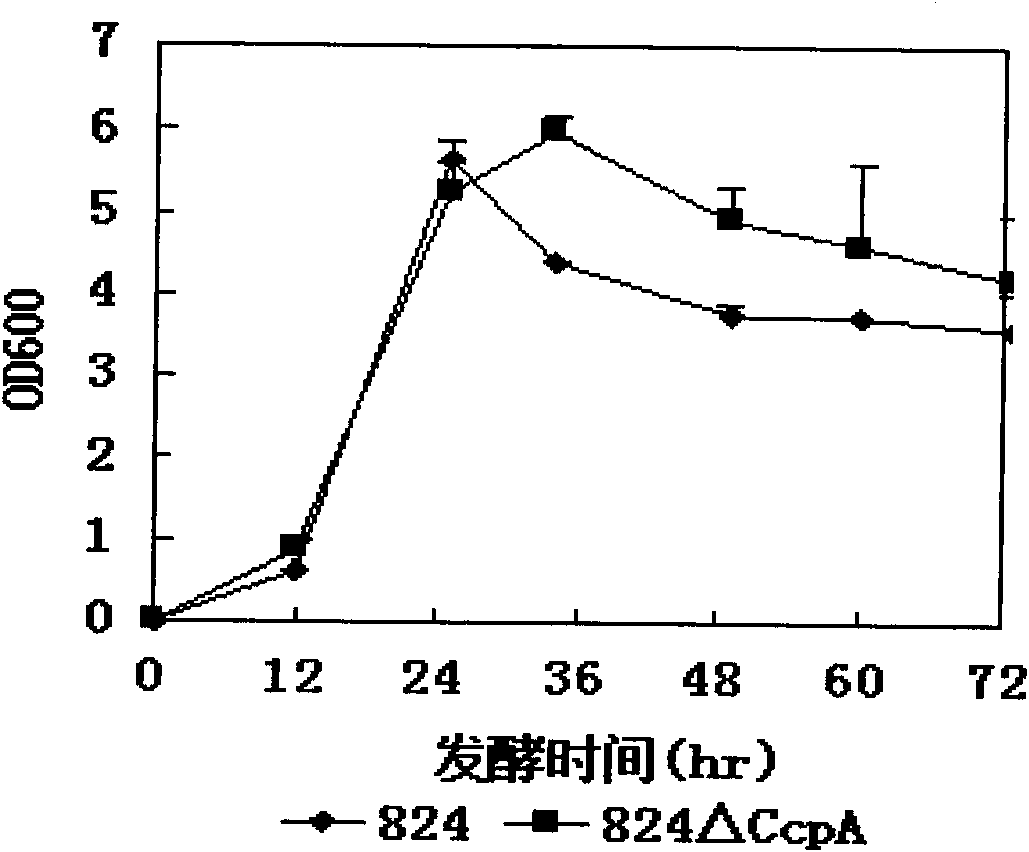

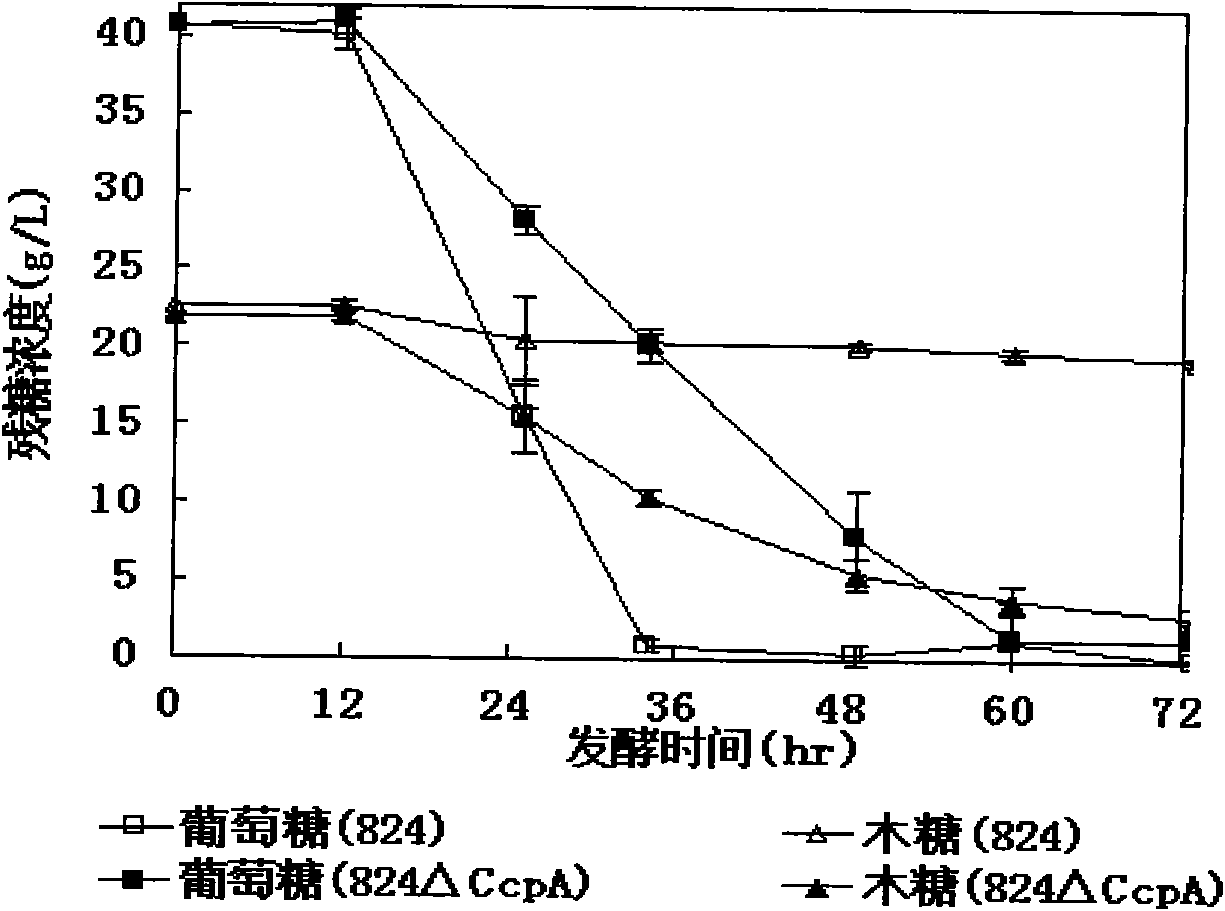

[0083] Example 3 , Clostridium acetobutylicum ccpA-mutant strain fermentation

[0084] Get the Clostridium acetobutylicum strain Clostridium acetobutylicum ccpA that has interrupted the ccpA gene obtained in step 2.2 - Ferment in P2 medium, and detect fermented liquid, specific process is as follows:

[0085] Pick a single bacterium from the CGM plate and inoculate it into 5mL CGM liquid medium, cultivate it overnight, inoculate it into 50mL CGM medium with 1% inoculum, cultivate it for 8-10 hours to reach a bacterial concentration OD600 of 0.4, and inoculate it into P2 culture with 5% culture medium, and at 0, 12, 25, 34, 48, 60, and 72 o'clock, the fermentation broth was taken, and the OD600 was detected (the results were as follows: figure 2 Shown), residual sugar content (use the sugar-pak column of WATERS company to measure through Agela 1200HPLC, the result is as follows image 3 Shown) and acetone, butanol and ethanol content (using Agela 7890A gas chromatograph to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com