Method for preparing cobalt-nickel metal or alloy powder by solution nebulization method

A solution atomization, alloy powder technology, applied in the field of powder metallurgy, can solve the problems of long process flow, strong toxicity, high equipment requirements, etc., to achieve simple and advanced preparation process, uniform and regular external appearance, high metal recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Configure 1.0mol / L CoCl 2 Solution, add ethanol according to the ratio of aqueous solution: ethanol volume ratio is 1:1, mix evenly;

[0020] (2) Input the solution into the airflow atomizer in the solution atomization special device (authorized, patent No. CN201361542Y), using high-purity nitrogen at an atomization pressure of 1.0×10 5 Atomized under Pa conditions, and then enter the vertical tubular electric furnace through the turbulence device in the special device, and react at a temperature of 800°C to obtain metal cobalt powder;

[0021] (3) The metal cobalt powder is separated and recovered by the two-stage high-efficiency cyclone dust collector and the first-stage bag filter in the prior art, and the acid gas in the gas phase is absorbed by the leaching absorption tower in the prior art to obtain industrial dilute hydrochloric acid.

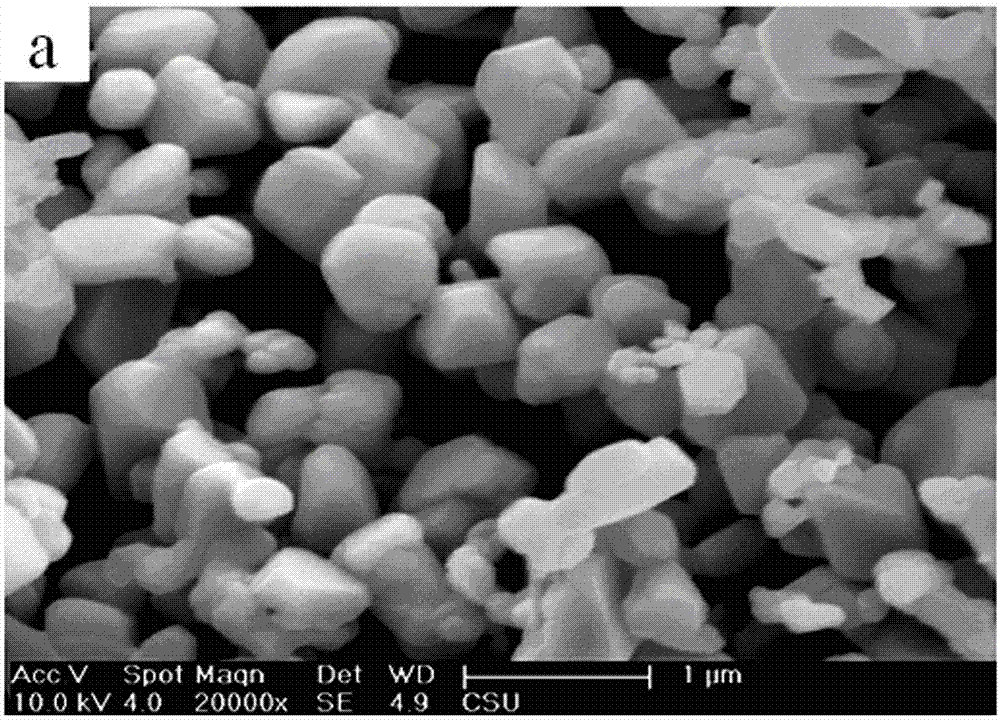

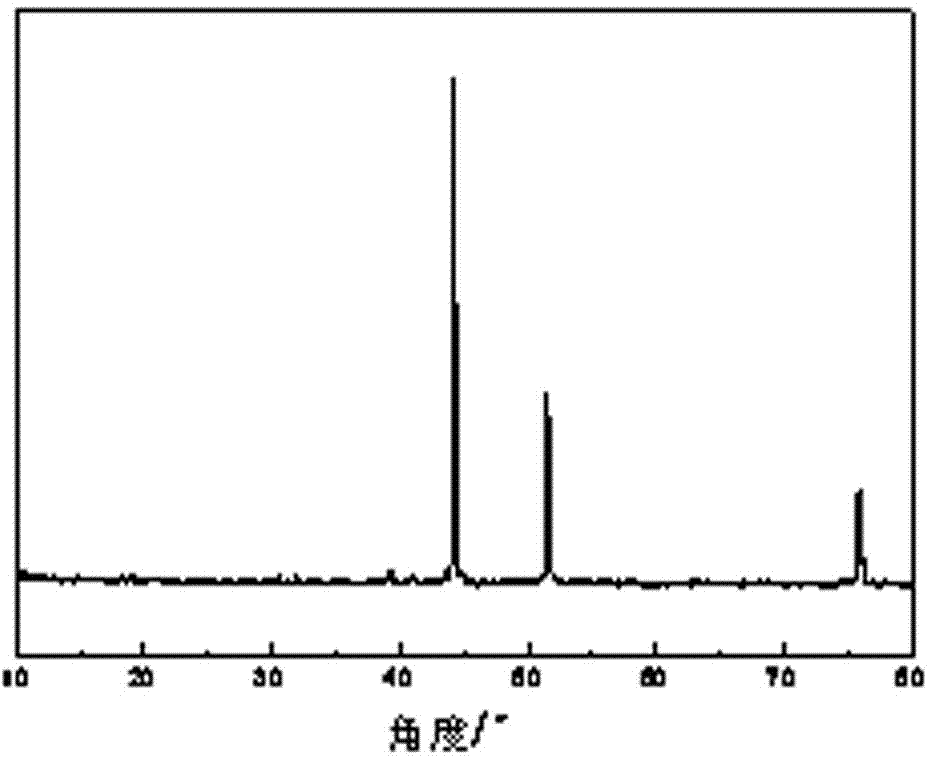

[0022] The obtained powder was detected by XRD, and the product was a single face-centered cubic cobalt powder; by SEM anal...

Embodiment 2

[0024] (1) Configure 2.0mol / L Co(NO 3 ) 2 Solution, add acetone according to the ratio of aqueous solution: acetone volume ratio of 1:3, mix well;

[0025] (2) Input the solution into the air-flow atomizer in the special device for solution atomization, using high-purity nitrogen at an atomization pressure of 1.5×10 5 Atomized under Pa conditions, and then enter the vertical tubular electric furnace through the turbulence device in the special device, and react at a temperature of 850°C to obtain metal cobalt powder;

[0026] (3) The metal cobalt powder is separated and recovered by the two-stage high-efficiency cyclone dust collector and the first-stage bag filter in the prior art, and the acid gas in the gas phase is absorbed by the leaching absorption tower in the prior art to obtain industrial dilute nitric acid.

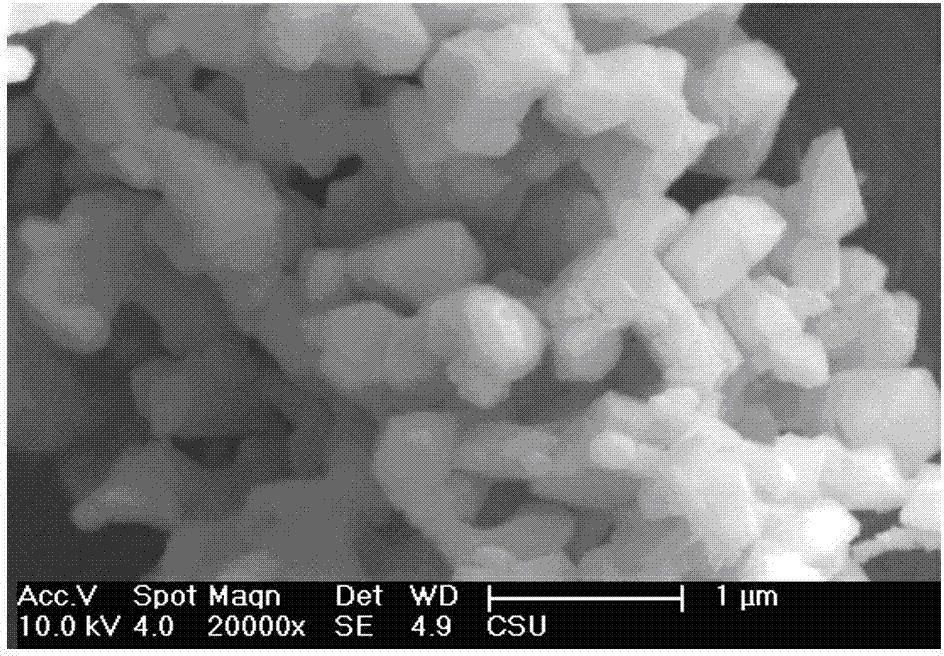

[0027] The obtained powder was detected by XRD, and the product was a single face-centered cubic cobalt powder; by SEM analysis, the product was uniformly dis...

Embodiment 3

[0029] (1) Configure 0.5mol / L CoSO 4 Solution, add methanol according to the ratio of aqueous solution: methanol volume ratio of 1:0.5, and mix well;

[0030] (2) Input the solution into the air-flow atomizer in the special solution atomization device, use high-purity nitrogen at an atomization pressure of 2.5×10 5 Atomized under Pa conditions, and then enter the vertical tubular electric furnace through the turbulence device in the special device, and react at a temperature of 850°C to obtain metal cobalt powder;

[0031] (3) The metal cobalt powder is separated and recovered by the two-stage high-efficiency cyclone dust collector and the first-stage bag filter in the prior art, and the acid gas in the gas phase is absorbed by the leaching absorption tower in the prior art to obtain industrial dilute sulfuric acid.

[0032] The obtained powder was detected by XRD, and the product was a single face-centered cubic cobalt powder; by SEM analysis, the product was uniformly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com