Method for preparing oat bran dietary fiber food

A technology of oat bran and dietary fiber, applied in food preparation, food science, application, etc., can solve the problems of low physiological activity and rough taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of oat bran:

[0049] The unique nutritional ingredient β-glucan in oat bran is mainly concentrated in the cell wall of oat sub-aleurone layer. In the general processing method of oat grains, the yield of oat bran accounts for 25%-30% of oat grains (raw materials) during the milling process. %, most of the β-glucan exists in the bran, and a small part of it exists in the oatmeal powder. General processing method The β-glucan in oat bran is 5%. The finished product rate of oat bran in the preparation process of the present invention accounts for 35%-40% of oat grains, the whiteness and fineness of oat fine powder increase, and the content of active ingredient β-glucan in oat bran increases, and the β-glucan is 6 %.

[0050] Edible oat bran preparation of oats: including raw grain cleaning, stone removal, impurity removal, water washing, milling and crushing, and edible oat bran is separated from oats during the milling process.

Embodiment 2

[0052] Preparation of oat bran into oat dietary fiber food by high temperature resistant α-amylase

[0053] Process flow: Oat bran → 0.2%-0.5% high-temperature-resistant α-amylase solution to wet the material, so that the water content of the wheat bran is 30%-60%, add calcium chloride 70-90mg calcium ion / kg water, soak at room temperature , the pH value is natural → the temperature is 90-100 ℃ steam or fry for 10-20 minutes, then increase the temperature of the frying pan, fry until the wheat bran is dry or dry in a microwave oven, extrude with a screw, and crush through a 40-mesh sieve , to obtain a finished product with a water content of less than 14%, a β-glucan content of more than 6%, and an obvious wheat flavor—oat bran dietary fiber food.

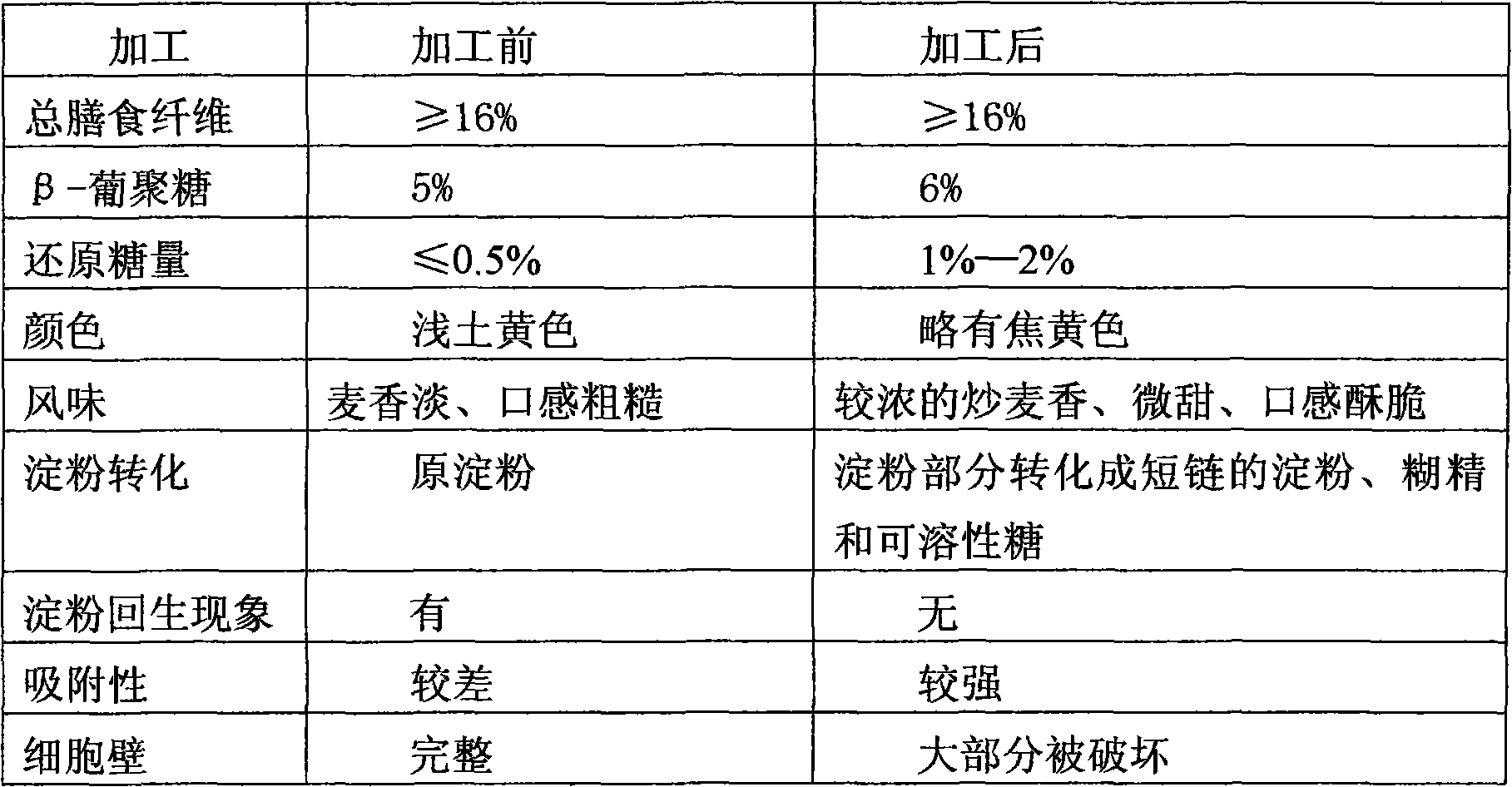

[0054] Table 1. Comparison of properties of oat bran before and after using high temperature resistant α-amylase

[0055]

Embodiment 3

[0057] As a food emulsifier and thickener, oat dietary fiber food is used in baked food and staple food to increase food viscosity, softness and crispness.

[0058]The use of oatmeal dietary fiber food in food ingredients can improve the dispersion and stability of ingredients, increase the water holding capacity and gas holding capacity of products, make the volume larger, looser and softer, and extend the shelf life. If it is used in soy sauce, it has a uniform body, is not easy to precipitate, and has increased viscosity. It not only has good stability, but also has a smoother taste.

[0059] Application in baked food Dietary fiber food base is the most widely used in baked food, the main products are high dietary fiber bread, cakes, biscuits, peach cakes, etc., the added amount of dietary fiber food is 5%-6%, with wheat flavor , good taste, no rough taste of wheat bran.

[0060] Application in staple food Oatmeal dietary fiber food is used in staple food such as steamed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com