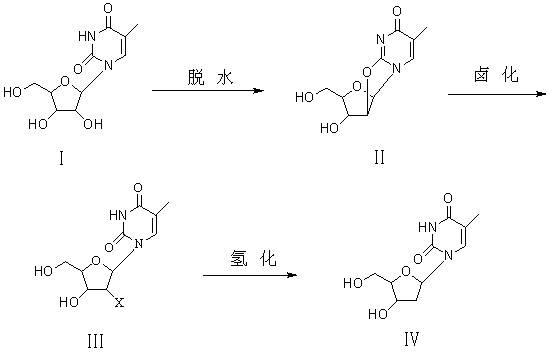

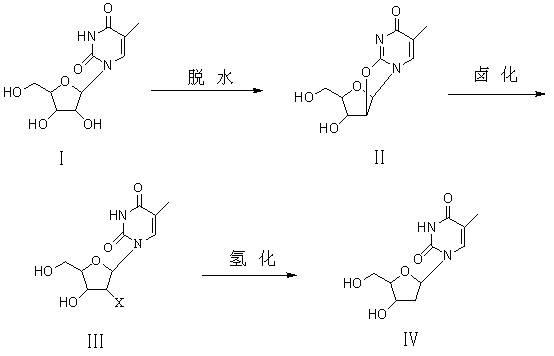

Preparation method of beta-thymidine

A technology of thymidine and equation, applied in the field of preparation of β-thymidine, can solve the problems of lack of stereospecificity of β-thymidine reaction, low utilization rate of raw materials, complicated separation process, etc., and achieve low cost, high cost and high product quality The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Add 25.8g of 5-methyluridine (0.1mol) and 25.7g of diphenyl carbonate (0.12mol) into 60ml of MDAC, start stirring and raise the temperature to 90°C, after the solid dissolves, add 1g of NaOH to reflux After keeping for 1 hour, after using TCL to measure the absence of raw materials, the solvent was distilled off under reduced pressure under cooling. After the distillation, cooling crystallized and filtered to obtain 21.9 g of intermediate (II) in the form of colorless crystal powder, with a yield of 94%.

[0027] In this embodiment, diphenyl carbonate is replaced with dimethyl carbonate, diethyl carbonate, dipropyl carbonate or dibutyl carbonate; the solvent is replaced with one or more mixed solvents in DMF, MDAC or acetonitrile MDAC, using KOH instead of NaOH, can achieve the above effects.

Embodiment 2

[0028] Example 2 Add 25.8g of 5-methyluridine (0.1mol) and 32.1g of diphenyl carbonate (0.15mol) into 60ml of DMF, start stirring and raise the temperature to 90°C, after the solid dissolves, add 1.5g of KOH to reflux After heat preservation for 2 hours, after no raw material was determined by TCL, the solvent was distilled off under reduced pressure under cooling, crystallized by cooling after distillation, and filtered to obtain 22.1 g of intermediate (II) in the form of colorless crystal powder, with a yield of 95%.

Embodiment 3

[0029] Example 3 Add 25.8g of 5-methyluridine (0.1mol) and 10.8g of dimethyl carbonate (0.12mol) into 50ml of DMF, start stirring and raise the temperature to 120°C, after the solid dissolves, add 1g of KOH to keep it under reflux After 3 hours, after no raw materials were measured with TCL, the solvent was distilled off under reduced pressure under cooling. After the distillation, cooling crystallized and filtered to obtain 22.1 g of colorless crystal powdery intermediate (II), with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com